Method for reinforcing concrete weak beam

A concrete beam and concrete technology, applied in building maintenance, construction, building construction, etc., can solve the problems of insufficient bearing capacity, reduced strength of concrete and steel bars, poor construction quality, etc., to improve the bending resistance and increase the effective height. , the effect of strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

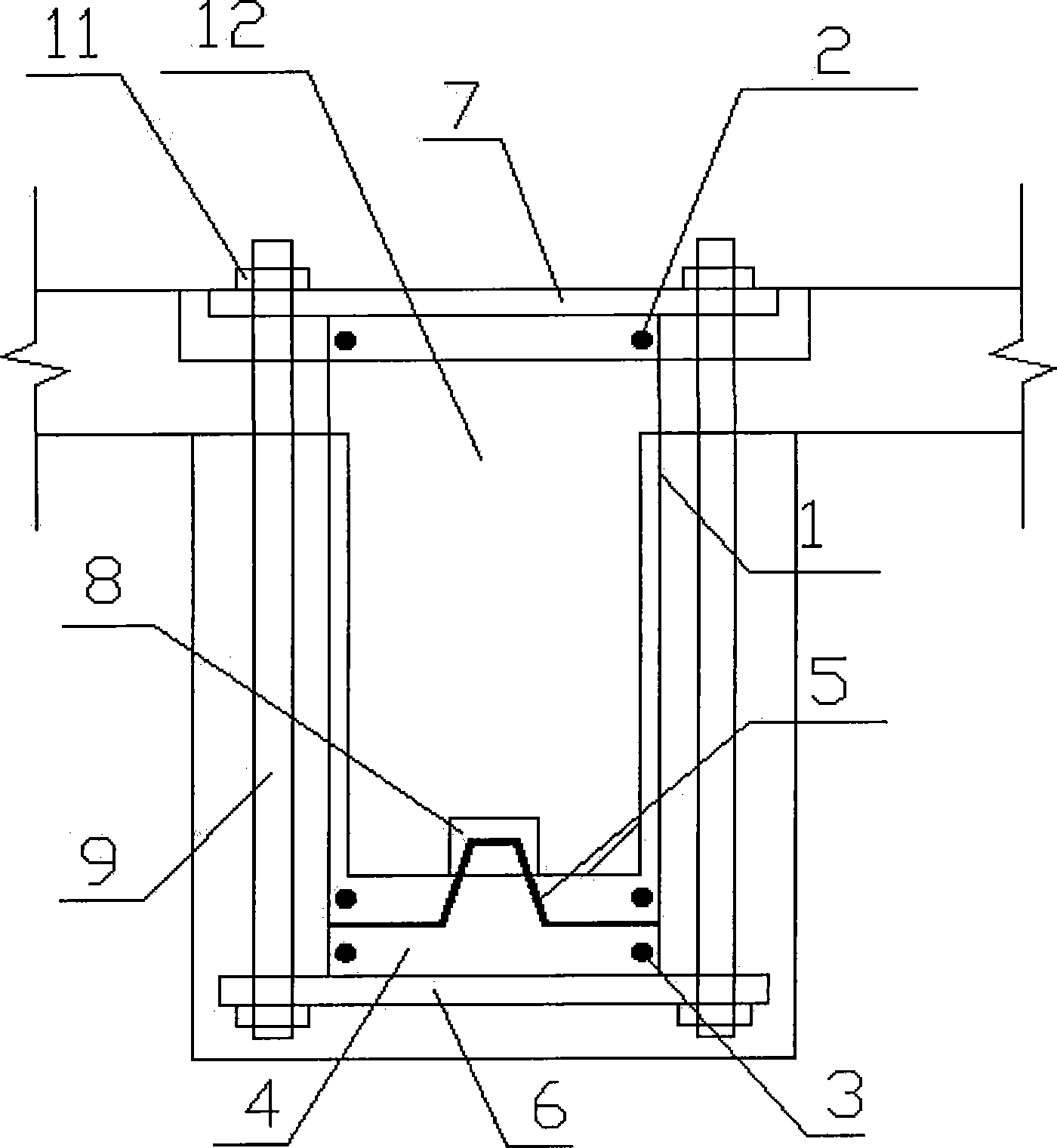

[0015] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0016] figure 1 It is a schematic diagram of the reinforcement structure of a concrete sick beam, and the reinforcement structure of a concrete sick beam includes a stirrup 1, a negative reinforcement 2, a main reinforcement 3, a reinforcement body 4, a steel bar stool 5, a steel support plate 6, a steel cover plate 7, and a high-strength epoxy resin mortar 8 , prestressed strut 9, shotcrete 10, prestressed anchor 11, concrete beam 12, negative reinforcement 2 is set on the upper part of concrete beam 12, and the diameter of negative reinforcement 2 is 22 mm, and two main reinforcements 3 are arranged on the lower part of concrete beam 12, and the diameter of main reinforcement 3 is 22mm, the lower part of the concrete beam 12 is provided with a groove, the groove depth is 50mm, the groove width and length are 70mm, the reinforced horse stool 5 is anchored into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com