Flat plate heat pipe

A flat heat pipe and top plate technology, applied in the field of heat pipes, can solve the problems of reducing the flow velocity of the working fluid and reducing the heat transfer efficiency of the flat heat pipe, achieving superior performance, small thermal resistance, and guaranteed heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

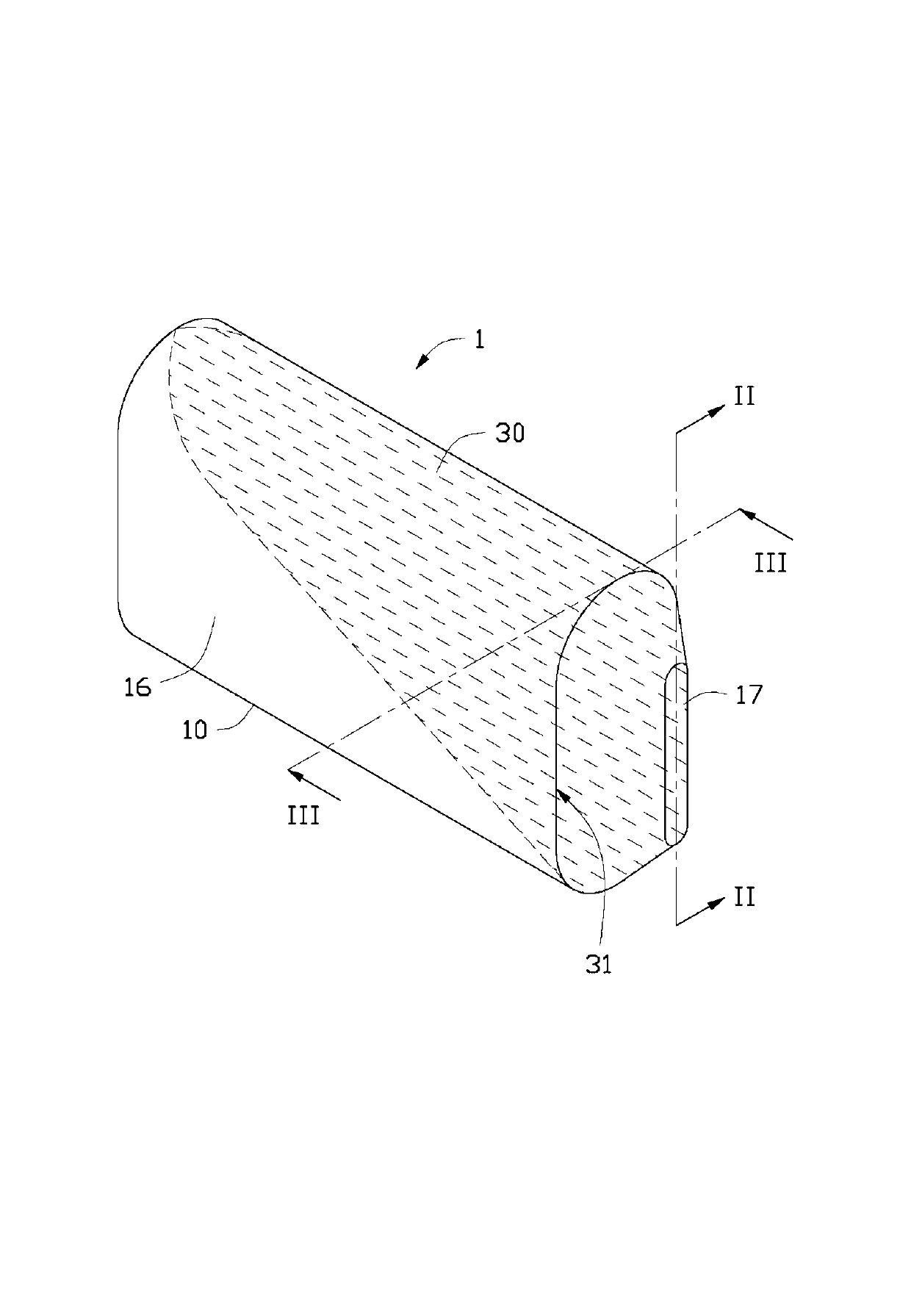

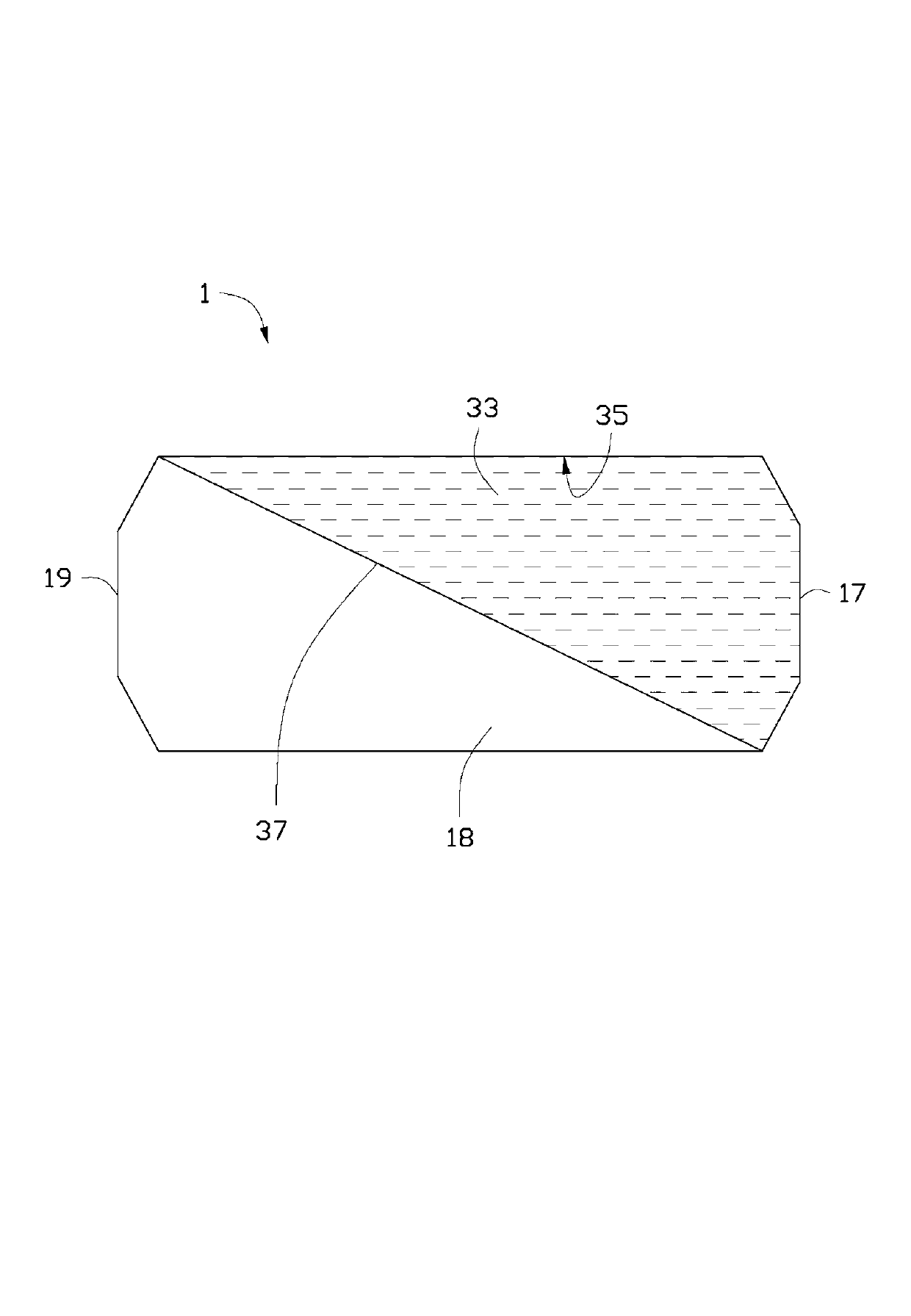

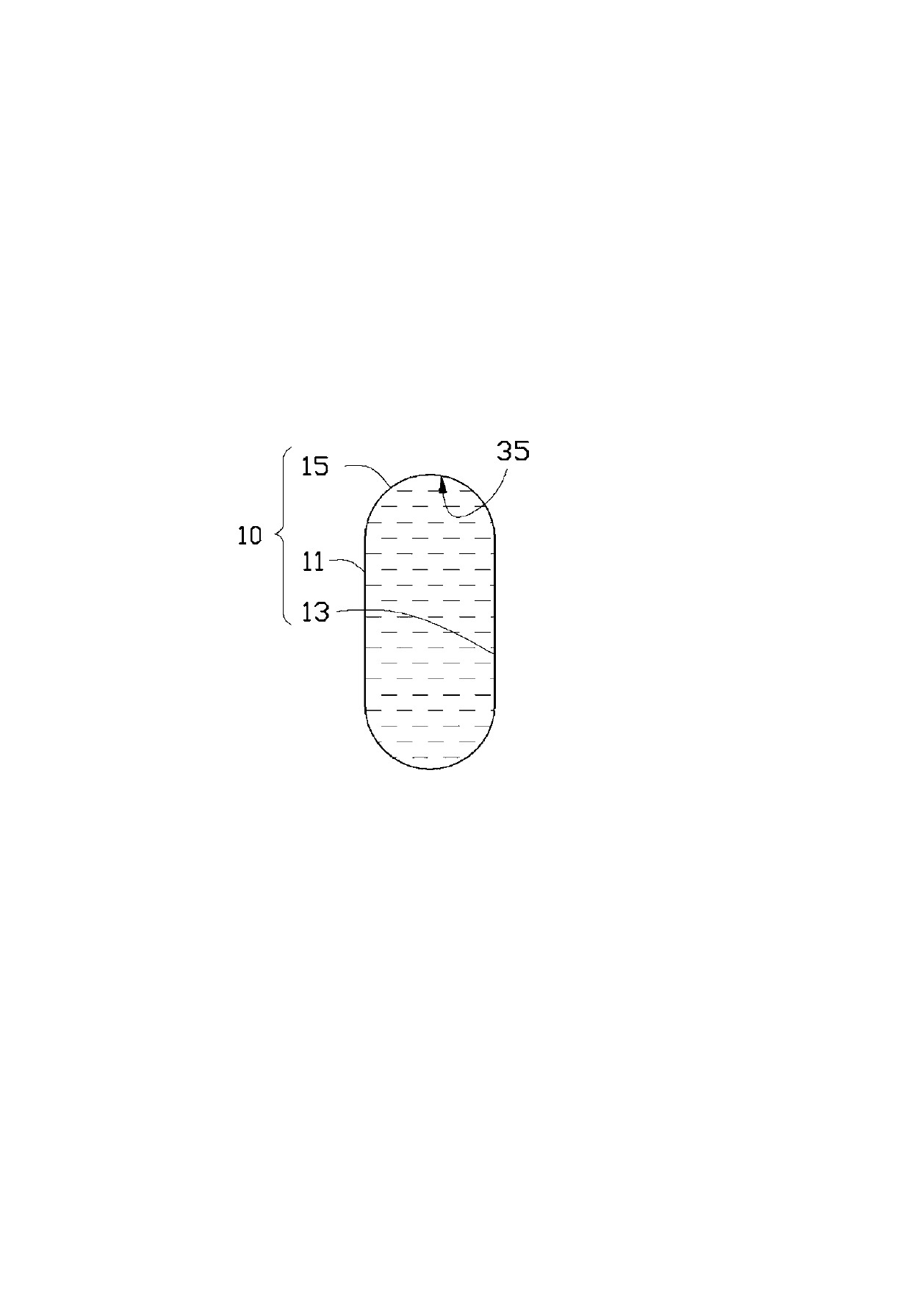

[0023] Such as Figure 1 to Figure 3 Shown is the flat heat pipe 1 of the first embodiment of the present invention. The flat heat pipe 1 includes a shell 10, a capillary structure 30 attached to the inner surface of the shell 10, and a working medium (not shown) contained in the shell 10.

[0024] The housing 10 is made of metal with good thermal conductivity, and includes a longitudinal top plate 11, a longitudinal bottom plate 13 located on one side of the top plate 11 and parallel to the top plate 11, and connecting the top plate 11 and the opposite side edges of the bottom plate 13 The two convex arc connecting plates 15. The opposite ends of the top plate 11 and the bottom plate 13 are flattened to form a first end 17 and a second end 19 that are close to each other, so that the top plate 11, the bottom plate 13 and the two connecting plates 15 together form a sealed containment Space 16. In the longitudinal direction of the flat heat pipe 1, a section extending from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com