Chip mounter detection device

A detection device and placement machine technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult-to-focus optical identification, placement offset, and impact on visual accuracy, so as to achieve uniform and soft illumination and improve Increased accuracy and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

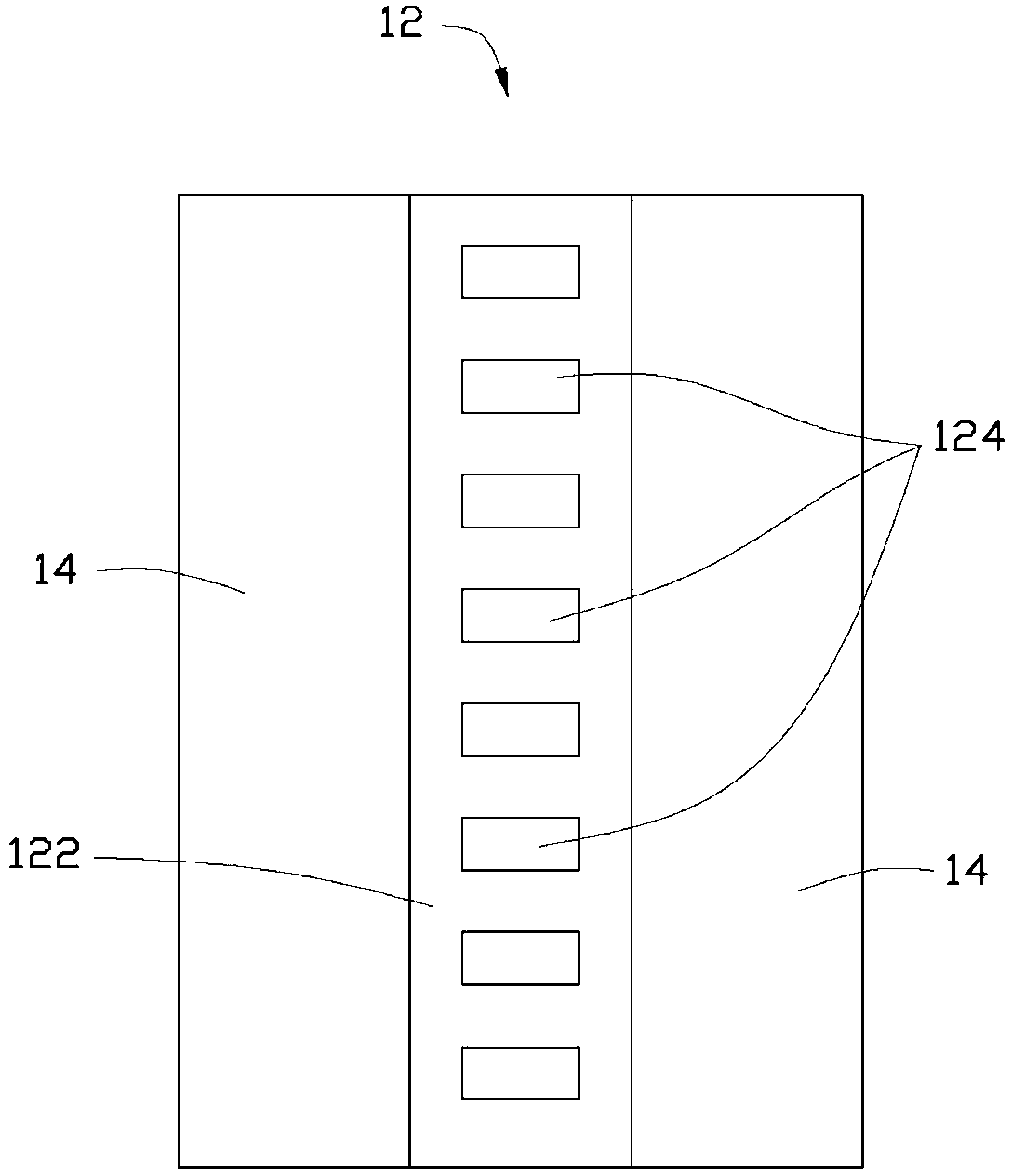

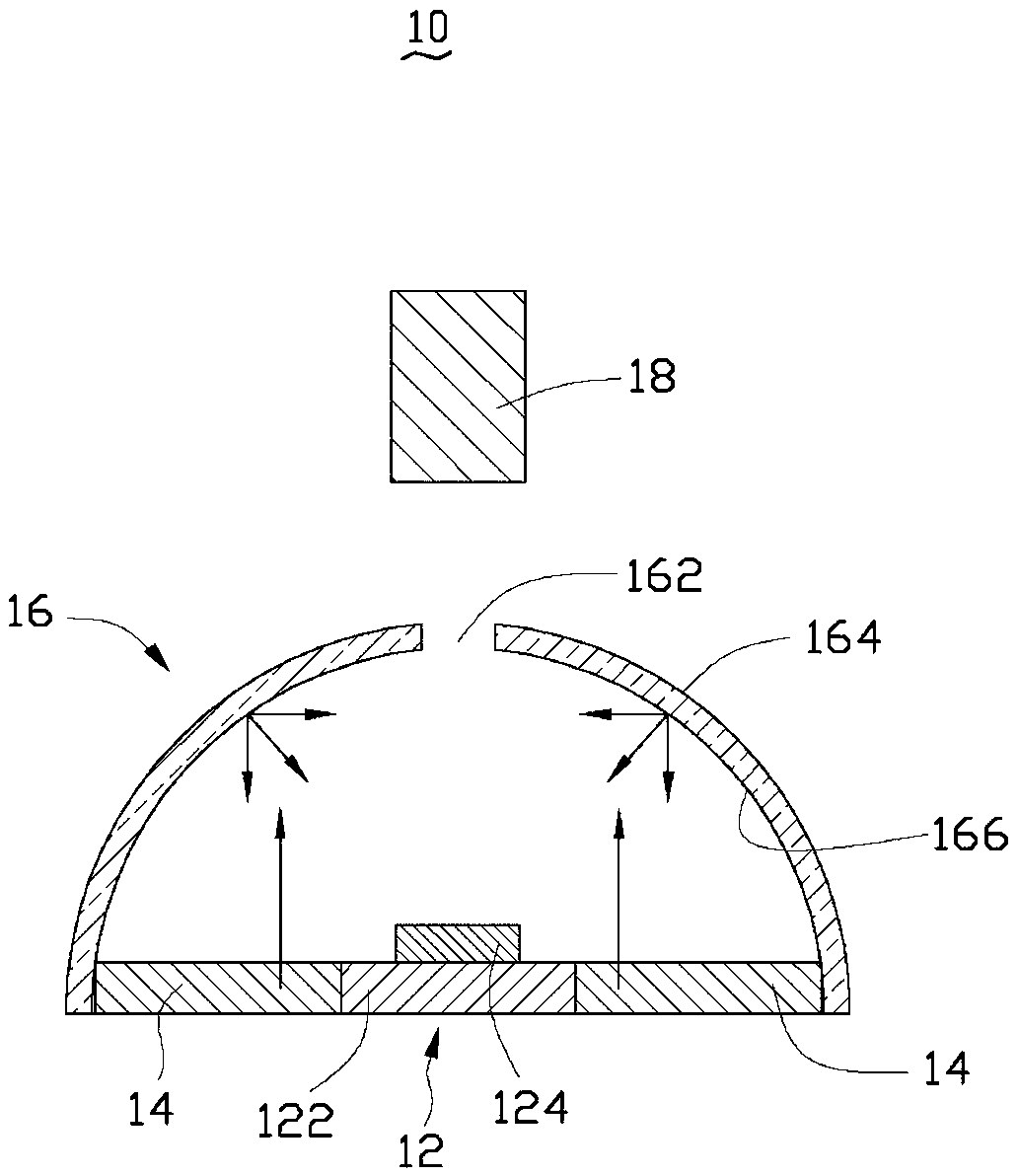

[0012] see figure 1 and figure 2 As shown, a top view of the component to be tested and a light source arrangement of the chip mounter detection device of the present invention, and a side view of the chip mounter detection device of the present invention are respectively provided. The detection device 10 of the placement machine of the present invention includes a component to be tested 12 , a light source 14 , a cover 16 and a camera module 18 . Wherein the component to be tested 12 comprises a circuit board 122 and a plurality of patch components 124, the sticking position of the patch component 124 is predetermined on the described circuit board 122, and the patch component 124 is formed by the patch Machine (not marked in the figure) is pasted on the predetermined pasting position. In this embodiment, the component to be tested 12 is an LED light bar, the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com