Novel crude oil sample detection mixer

A technology for detecting samples and mixers, which is applied in the field of oil injection rotary agitation and multi-helical blade shearing crude oil detection sample mixers, which can solve the problem of low mixing uniformity, high temperature of mixed liquid and non-continuous production in terms of use effect and other problems, to achieve the effect of simple structure, less loss of components, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

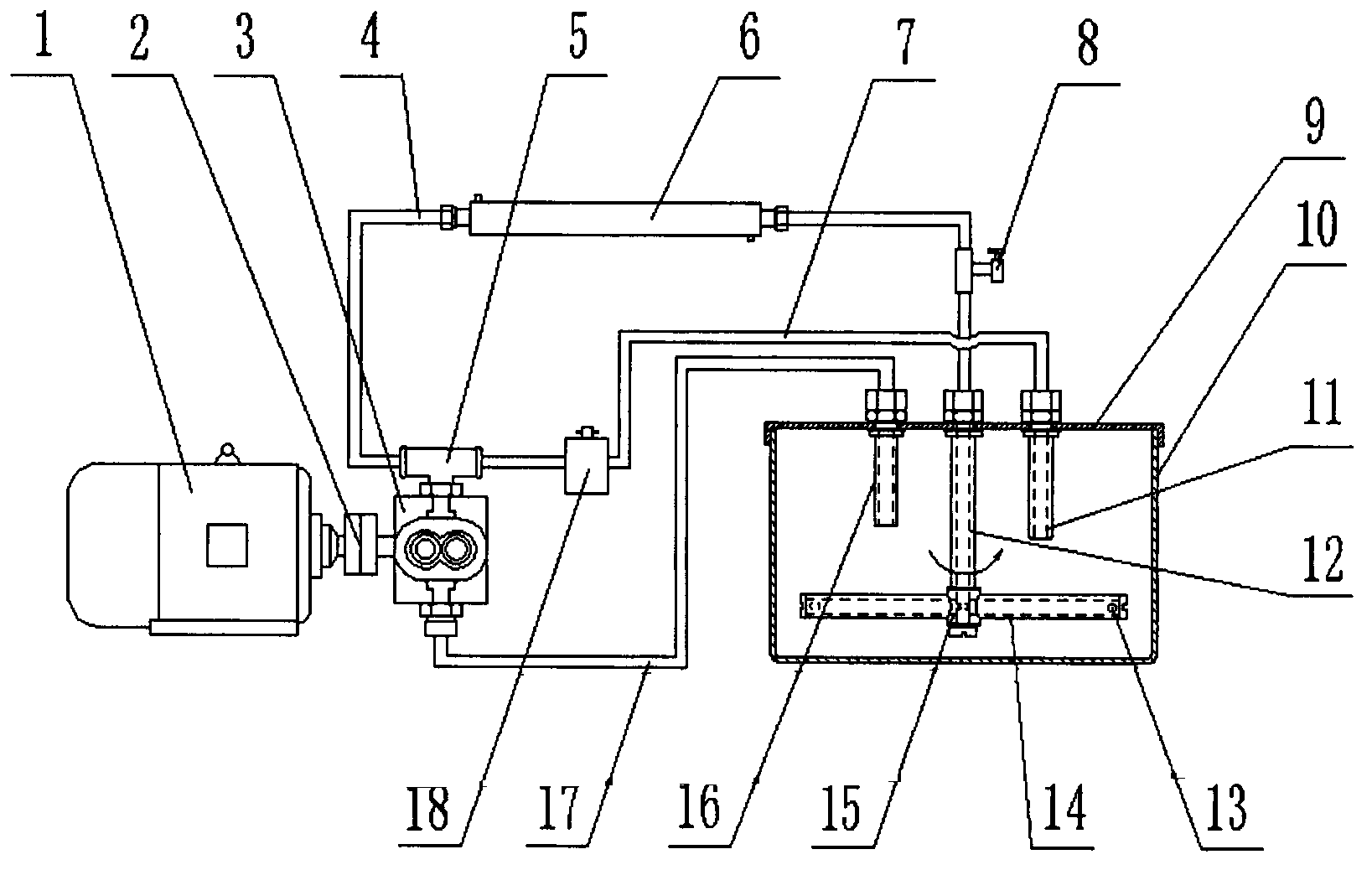

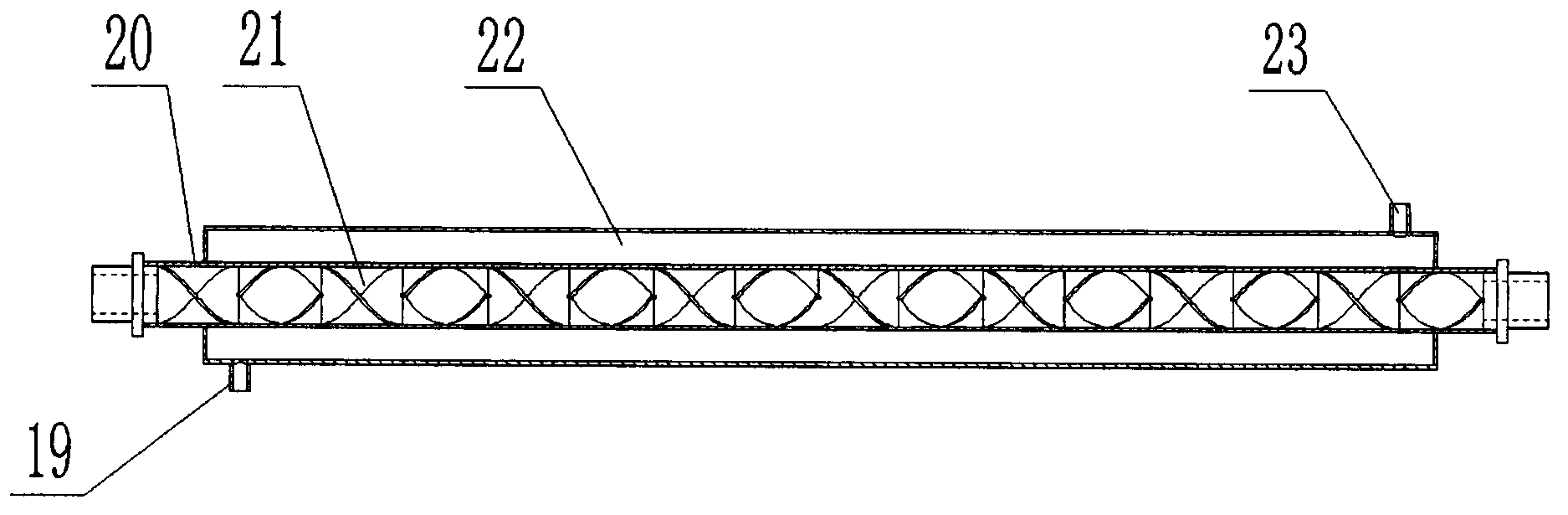

[0016] refer to figure 1 , figure 2 , is an embodiment of a novel crude oil detection sample mixer, comprising a motor (1), an oil pump (3), an oil inlet pipeline (17), an oil outlet pipeline (4), an oil overflow pipeline (7), a spiral blade Mixing device (6), overflow valve (18), three-way pipe joint (5), sampling valve (8) and oil injection rotary stirring device, characterized in that the motor (1) is connected to the machine through a coupling (2) On the oil pump (3), the described oil injection rotary stirring device is composed of a mixing container (10), a mixing container cover (9), an oil suction port (16), an oil overflow port (11), a central oil return rod (12), a stirring The cross bar (14) and the sleeve (15) are composed, the mixing container cover (9) is arranged on the upper side of the mixing container (10), and the oil suction port (16) and the oil overflow port (11) are arranged on the mixing container cover (9) , the central oil return rod (12) is locate...

Embodiment 2

[0018] The difference between this embodiment and embodiment 1 is that the agitating cross bar is more than two cross bars.

Embodiment 3

[0020] The difference between this embodiment and embodiment 1 is that the agitating bar is a disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com