Micro-gap type contact angle measuring instrument

A contact angle and measuring instrument technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to measure the liquid contact angle, and achieve the effect of good popularization and simple implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. But the following examples do not limit the protection scope of the present invention in any way.

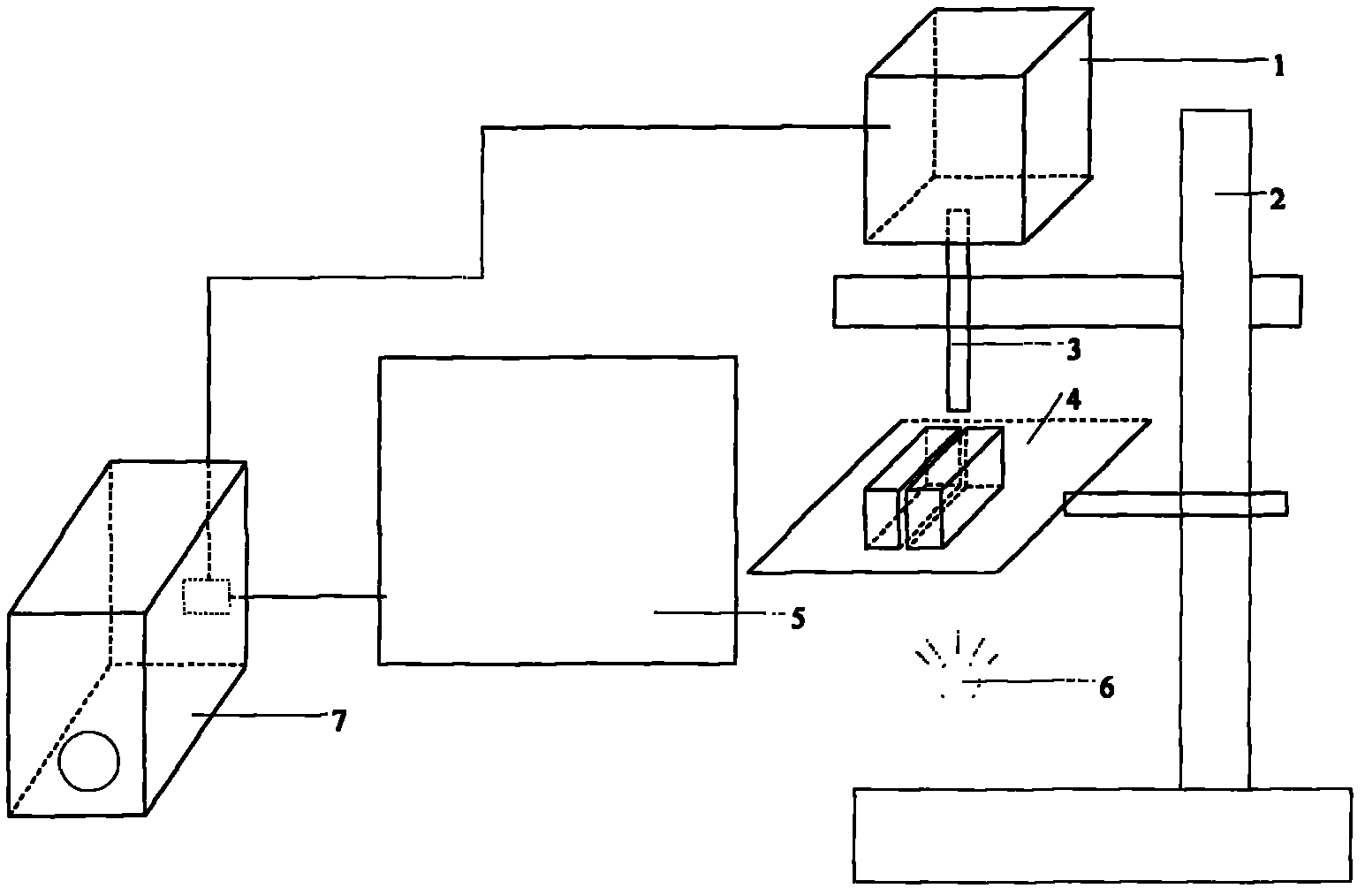

[0025] attached figure 2 It is the overall structure of the instrument of the present invention, mainly including five parts of sample measurement part (liquid sample, solid sample), microscopic magnification, photography (microscope), graphic intake (camera), data analysis (software), and computer control. Microscope, camera, commercial graphics processing software, and computer can be selected according to the needs of measurement. Here, the sample measurement part is mainly explained further.

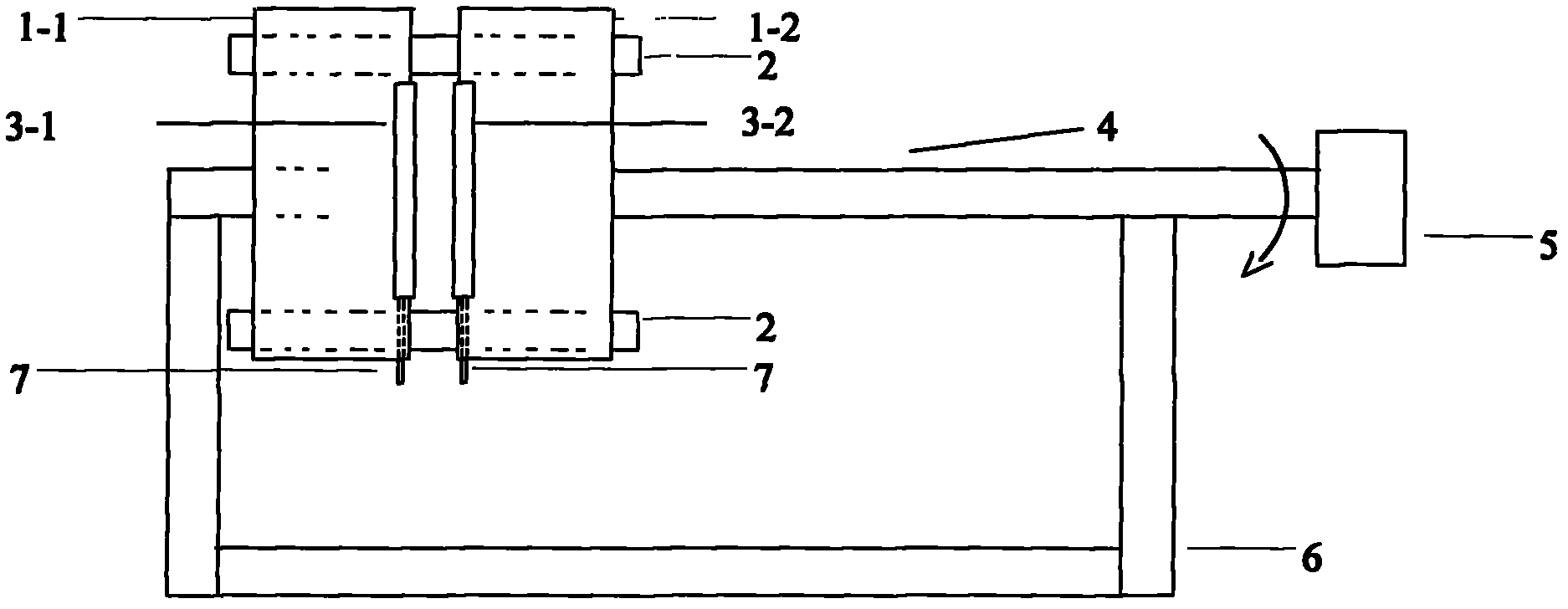

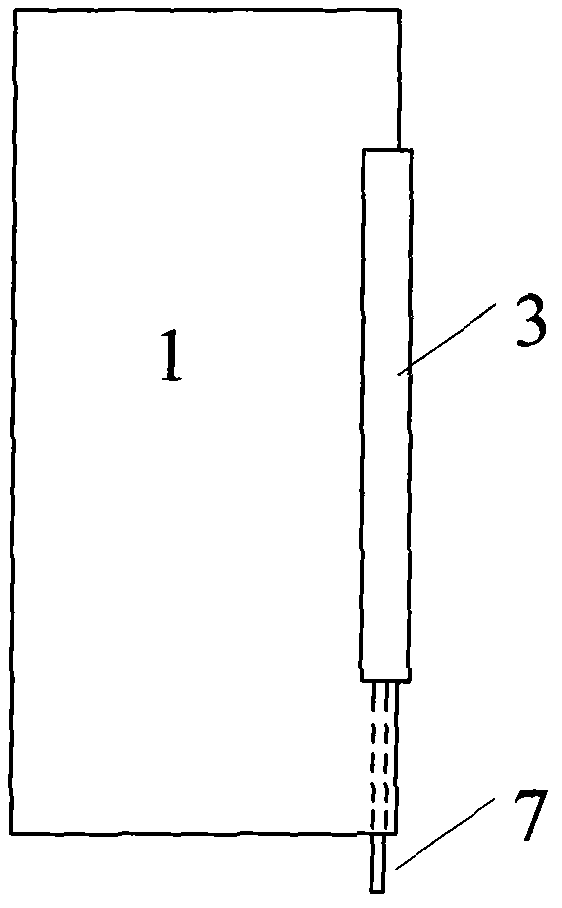

[0026] The sample is divided into two parts: solid sample and liquid sample. The sample measurement part mainly has three functions: solid sheet fixation, establishment and adjustment of micro gaps, and formation of contact angle of liquid in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com