Multi-channel multi-component stationary source sampling and analysis system

A sampling analysis and multi-component technology, which is applied in the field of pollutant emission analysis instruments, can solve the problems of less flue gas components, difficult analysis and reflection of pollutant emission trend changes, and achieve high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

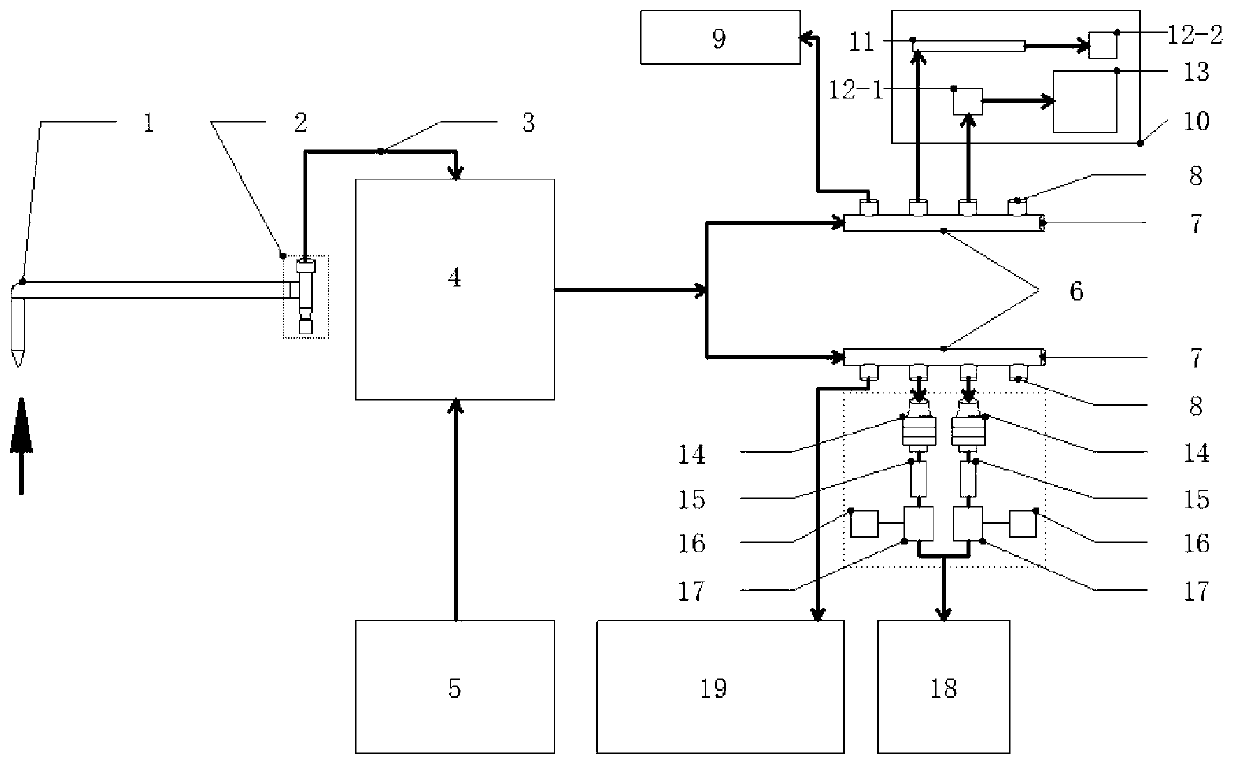

[0017] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] A multi-channel multi-component fixed source sampling and analysis system, including a sampling gun 1, the tail of the sampling gun 1 is connected to the inlet end of the particle cutting head 2 through a thread, and the gas outlet end of the particle cutting head 2 is passed through an MPS temperature-accompanied air-conducting hose 3 is connected to the air inlet of the MPS dilution system 4, and the air compressor 5 connected to the MPS dilution system 4 provides dilution air, and the air outlet of the MPS dilution system 4 is connected to the air inlets of the two air distribution pipes 6 through a pneumatic joint , the end of each gas distribution pipe 6 is provided with a gas exhaust port 7 with a one-way valve, and the main body of each gas distribution pipe 6 is provided with an equivalent sampling port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com