Concrete vibration quality monitoring and communication networking method

A quality monitoring and concrete technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of neglecting process data acquisition and management, sensor integration difficulties, data transmission interruption, etc., to achieve intelligent and networked to improve stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below according to accompanying drawing, the present invention is described in further detail:

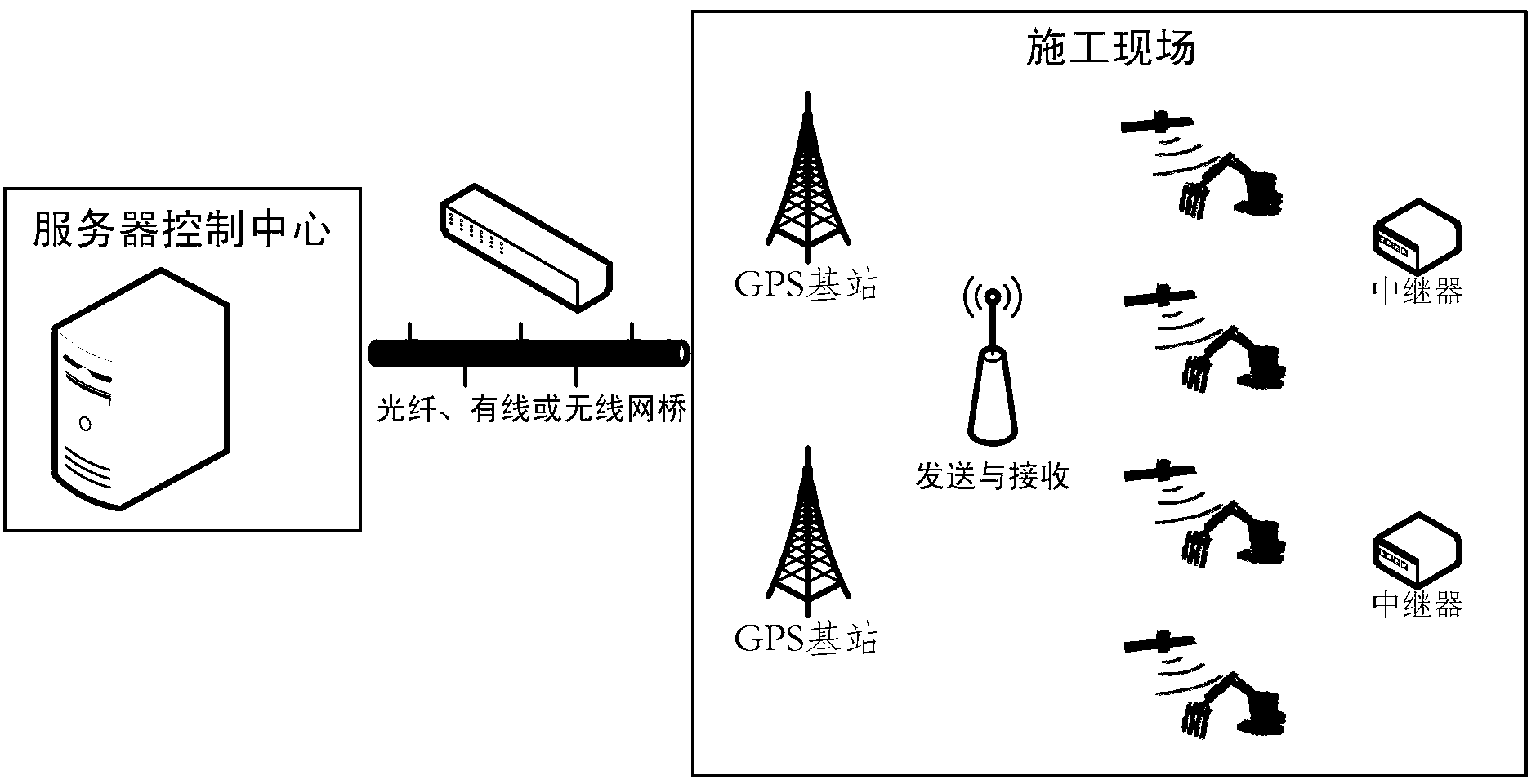

[0027] The concrete vibrating quality monitoring communication networking method proposed by the present invention, such as figure 1 As shown, the main technical solution is to propose a communication networking method for concrete vibration quality monitoring in the process of intelligent monitoring of concrete vibration quality. Reliability, greatly reducing data loss and data delay in message transmission and reception.

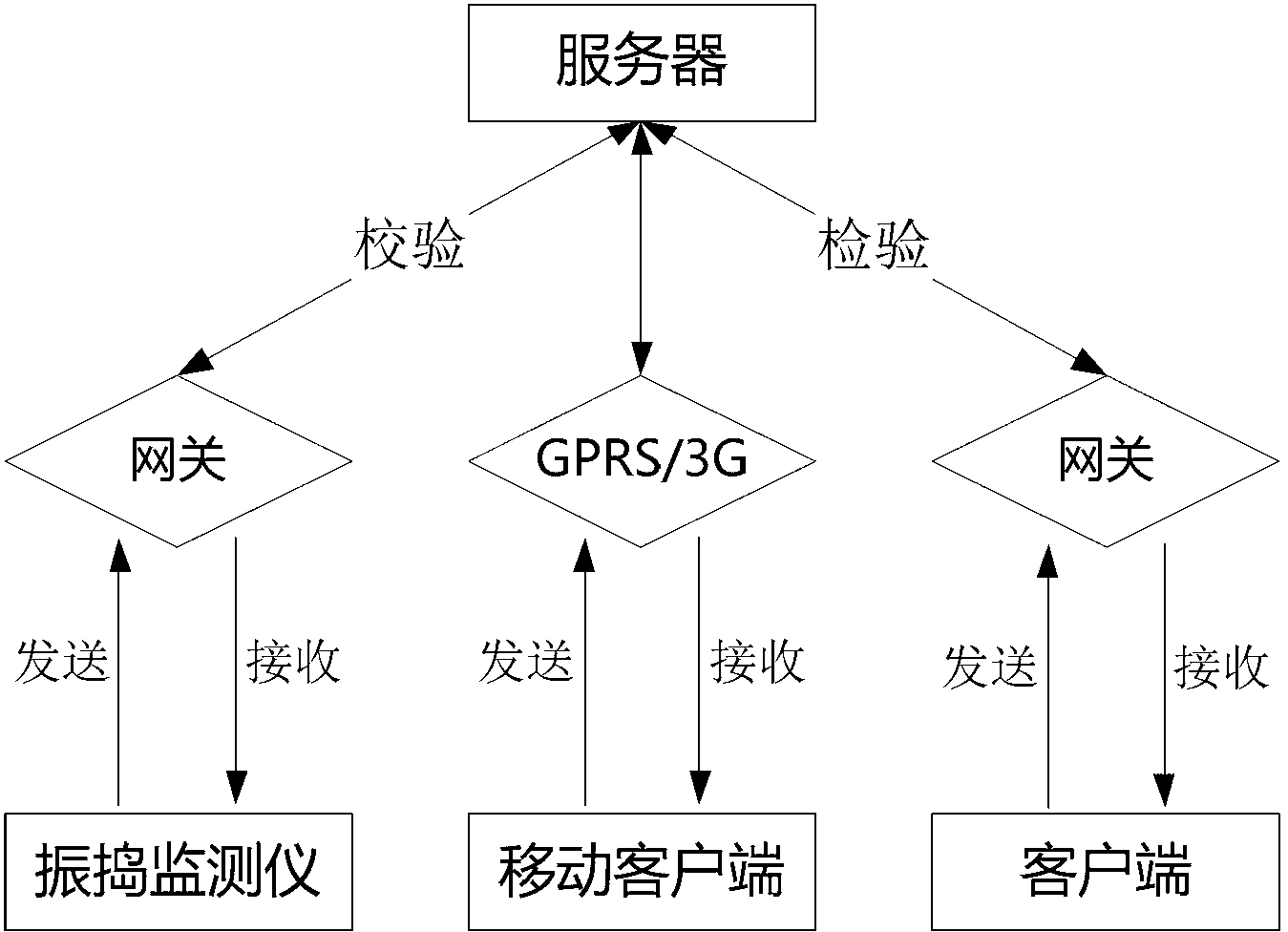

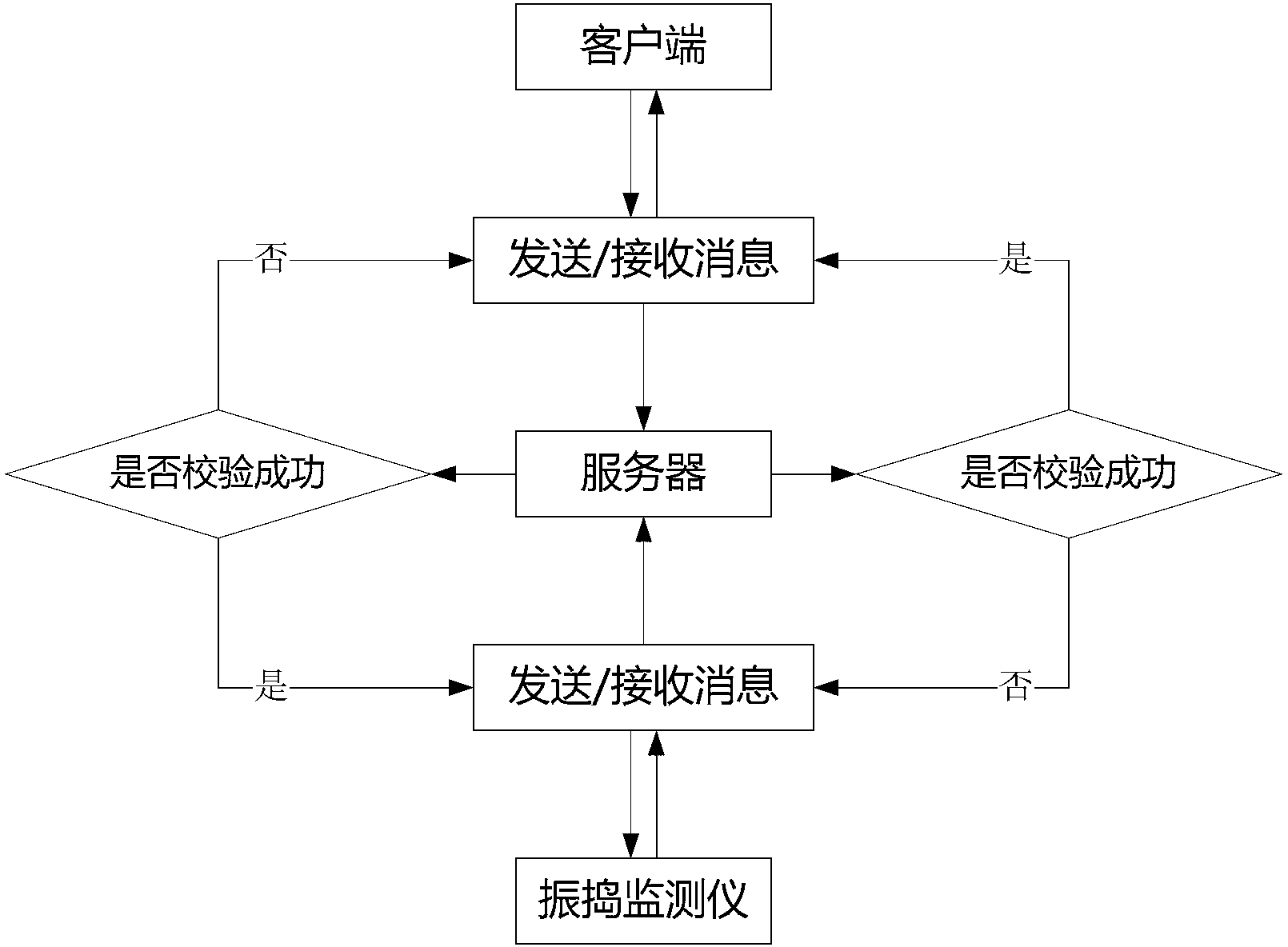

[0028] The technical solution adopted by the present invention to solve the core technical problem is: in the process of intelligent monitoring of concrete vibration quality, in order to ensure stable and reliable data transmission, wired (such as optical fiber and twisted pair), wireless (such as Wi-Fi), GPRS / 3G, RFID wireless radio frequency signals and other networks establish a communication networking method for concrete vibrating quality monitors....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com