A Design Method of High Frequency and High Voltage Transformer for Electrostatic Precipitation

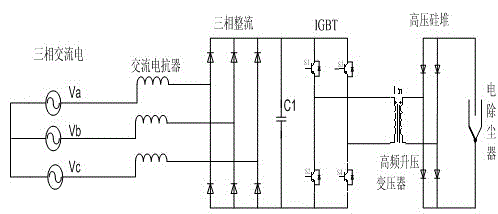

A high-frequency high-voltage, electrostatic dust removal technology, applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problems of low transmission power and low transmission efficiency, achieve high operating frequency, large transmission power, and improve operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

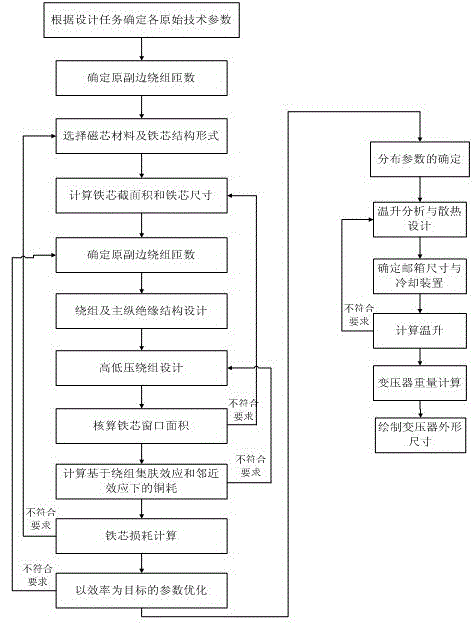

[0052] The present invention will be further described below with reference to the accompanying drawings and specific implementation methods.

[0053] like figure 1 and figure 2 As shown, it is a design flow chart based on high-frequency high-voltage transformation applied to electrostatic dust removal, and the specific steps are:

[0054] 1) Determine the original technical data according to the design task, determine the primary and secondary winding turns ratio, and determine the primary and secondary rated current;

[0055] 2) Select the magnetic core material and the iron core structure form, the present invention adopts the ultramicrocrystalline magnetic core as the transformer iron core, the selected ultramicrocrystalline iron core structure form is as follows Figure 5 shown. The iron core is made of 0.8mil (mil) thick ultrafine crystal core.

[0056] 3) Calculate the cross-sectional area of the iron core and the size of the iron core; the size of the iron core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com