Membrane electrode and manufacturing method thereof

A thin-film electrode and thin-film technology, which is applied in the field of thin-film electrode preparation, can solve the problems of easy loss of screen, increased cost, and difficulty in patterning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

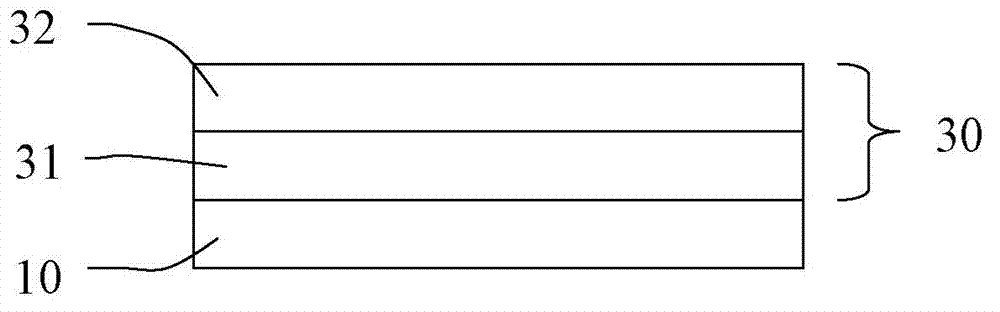

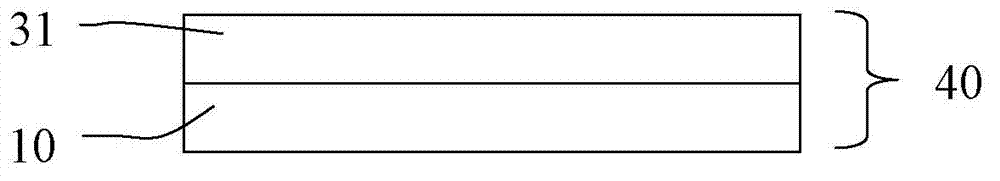

[0069] The steps of the method for preparing a thin film electrode of the present invention will be described below with reference to FIGS. 1 and 2 . First, if Figure 1a As shown, a substrate 10 is provided; then, as Figure 1b As shown, the transfer film 30 is placed on the substrate 10, wherein the transfer film 30 includes a paint layer 31 and an underlayer 32, and the paint layer 31 is interposed between the underlayer 32 and the substrate 10, in this way The paint layer 31 can be transferred on the substrate 10; finally, as Figure 1c As shown, the film electrode 40 can be formed by removing the underlayer 32 .

[0070] In addition, in the method of the present invention, if Figure 2a As shown, the conductive base material 20 may be formed on the base material 10 according to circumstances including the conductive layer 15 . Conductive layers suitable for use in the method of the present invention include, but are not limited to, those selected from the group consis...

Embodiment 1

[0079] Preparation of transfer film

[0080] Get 17.5 parts by weight of titanium dioxide (ST-21, manufactured by Ishihara Co., Ltd., Japan, with 100% solid content), 7.5 parts by weight of polyester resin (5016-TS, manufactured by Changxing Chemical Company, with 100% solid content) and 75 parts by weight of solvent N-octyl Based pyrrolidone (NOP), they are stirred and mixed uniformly at a high speed to prepare a coating composition with a solid content of about 25% by weight, wherein the average particle diameter of titanium dioxide is about 25 nanometers.

[0081] The above-mentioned coating composition was coated on a polyethylene terephthalate (PET) release film (model: A71, manufactured by Teijin DuPont Co., Ltd., film thickness 50 μm) with an RDS coating rod #7, and the coating thickness was The transfer printing film of the present invention can be obtained after drying at 130°C for 10 minutes, and the thickness of the coating layer after drying is 6 microns.

[0082]...

Embodiment 2

[0085] Repeat the steps of Example 1 to prepare the transfer film, except that the thickness of the coating film is changed to 12 microns, and the thickness of the dried coating layer is 3 microns.

[0086] Repeat the steps of Example 1 to prepare a thin film electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com