End socket assembly welding machine for low-temperature heat-insulating gas cylinder

A low-temperature heat insulation and welding machine technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of unguaranteed assembly quality, difficult control of weld quality, low assembly efficiency, etc., achieve simple structure, reduce production cost, The effect of high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

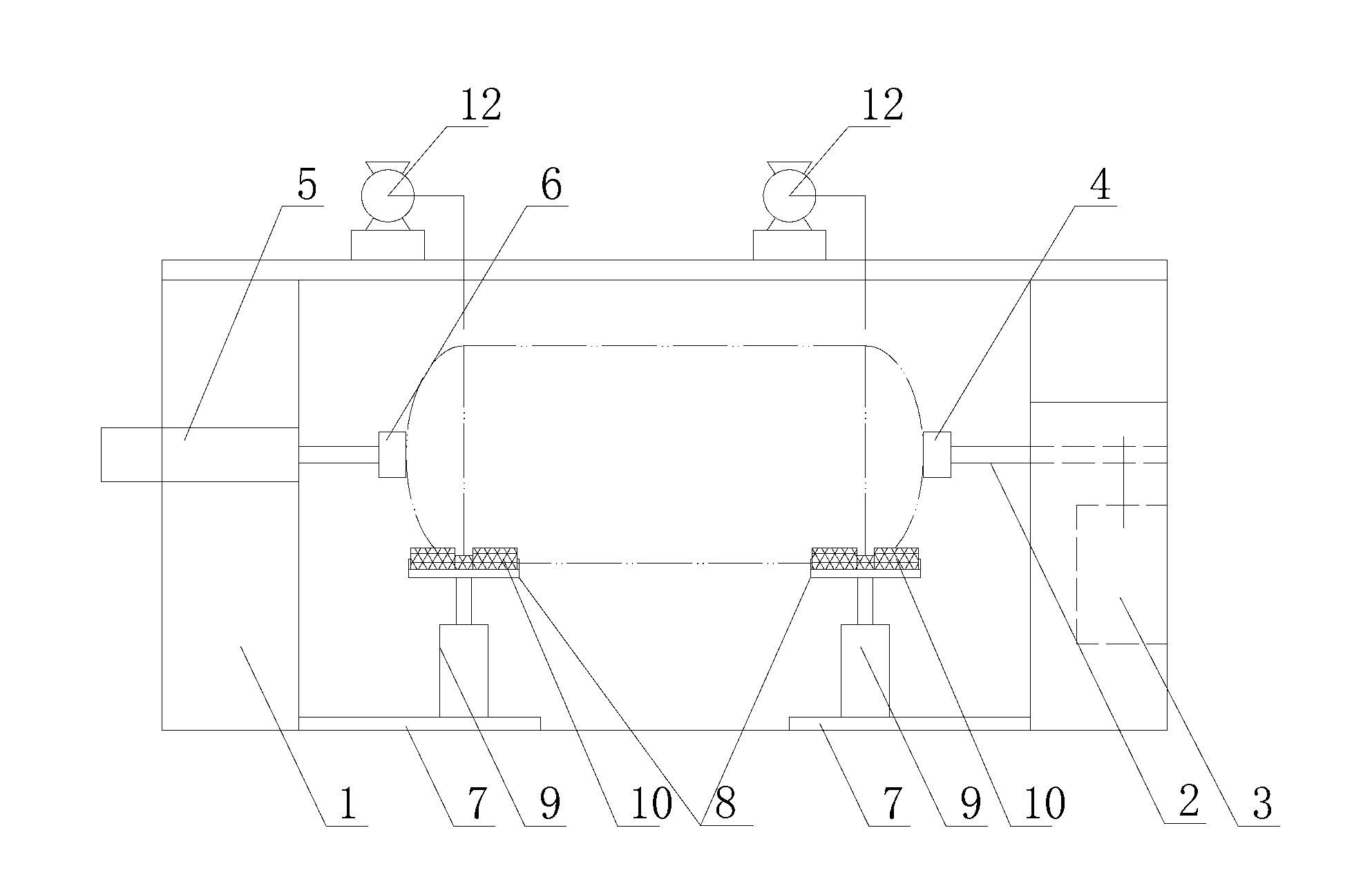

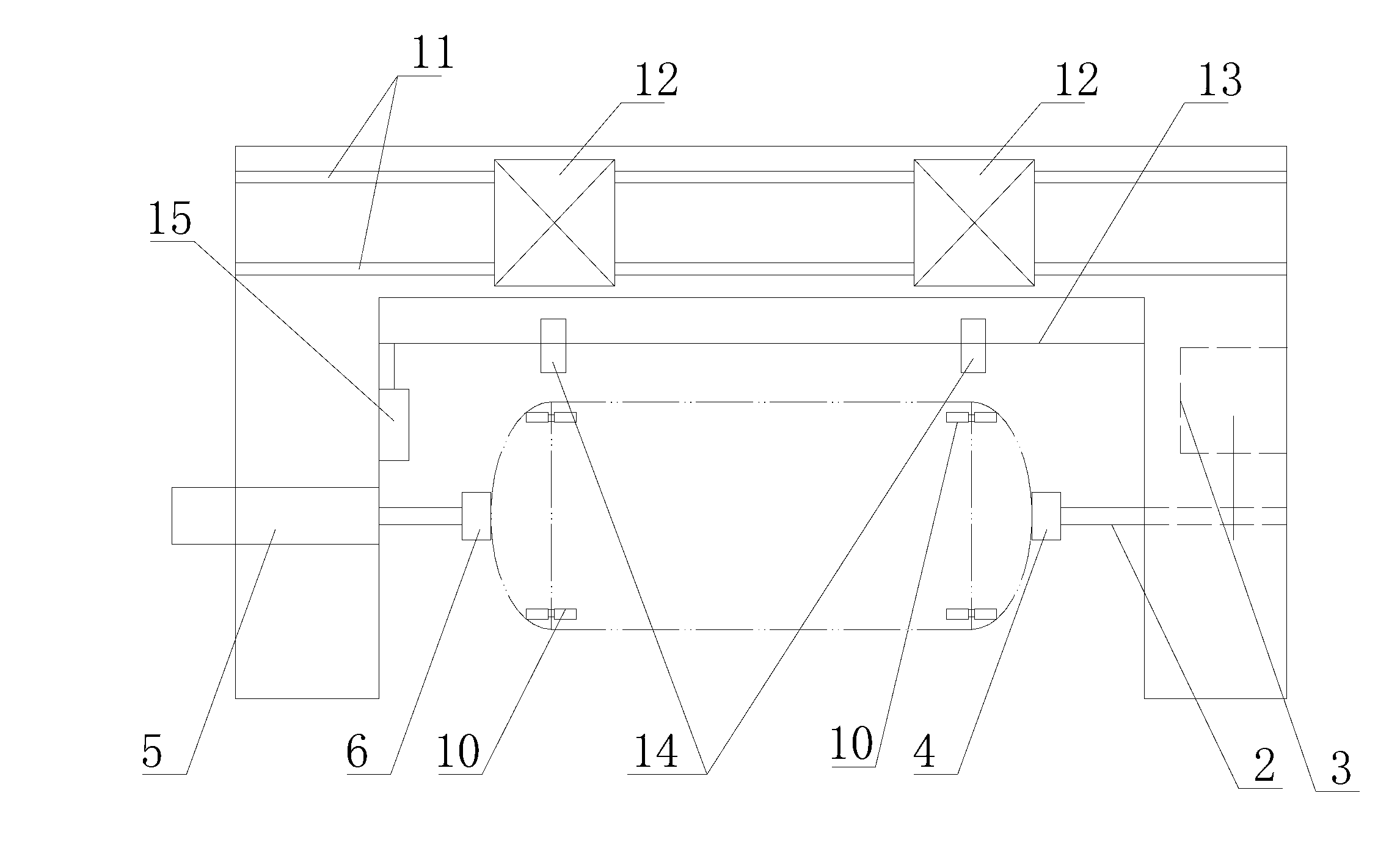

[0024] Such as Figure 1-2 As shown, the low-temperature insulation gas cylinder head assembly welding machine includes a frame 1, and the frame 1 is provided with a rotating shaft 2, and one end of the rotating shaft 2 is connected with a driving device 3 arranged on the frame 1, and the rotating shaft 2 The other end is provided with a fixed end rotary chuck 4, and the frame 1 is provided with a clamping cylinder 5 which moves axially along the gas cylinder, and the piston rod end of the clamping cylinder 5 is provided with a movable end rotary chuck 6. There are two bottle supporting devices on the frame 1. The bottle supporting device includes a bracket 7 which is arranged on the frame 1 and can be adjusted along the axial position of the gas cylinder. The bracket 7 is provided with a mounting plate 8 perpendicular to the axis of the gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com