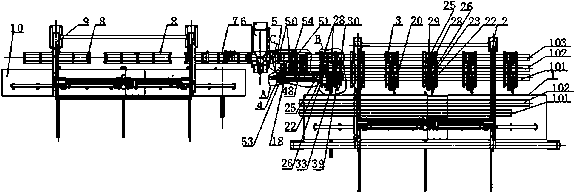

Production device and machining method for U-shaped longitudinal beam and lining beam automatic positioning beam combining spot welding

A technology for automatic positioning and production equipment, which is applied in the field of spot welding process, U-shaped longitudinal beam and its lining beam positioning, and combined beams. It can solve the problems of large area occupied by professional machinery, low handling, turning efficiency, and low positioning efficiency. , to achieve the effects of small footprint, improved operating environment for workers, and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

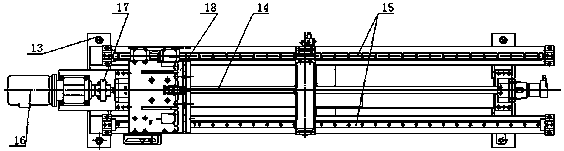

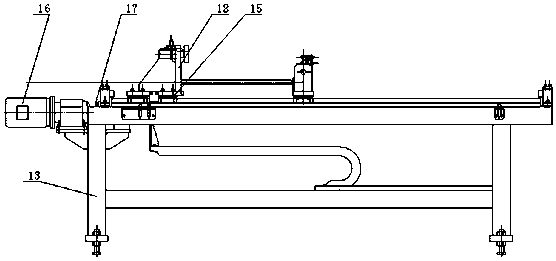

[0060] When the U-shaped longitudinal beam with automatic positioning and its lining beam are used for automatic beam closing and spot welding production equipment, a processing method for U-shaped longitudinal beam and lining beam automatic positioning beam spot welding, which includes the following steps:

[0061] (1), place the U-shaped longitudinal beam 102 and the lining beam 101 on the feeding platform 1 respectively, for standby;

[0062] (2) Use the feeding extraction device 2 to suck and lift the spare U-shaped stringer 102 , and lift the U-shaped stringer 102 with the opening upward directly to the stringer feed roller 25 and the stringer feed roller 48 . For the U-shaped longitudinal beam 102 with the opening downward, it is lifted to the automatic turning device 20 first, and the automatic turning device 20 turns it over 180°, and pulls it to the lining beam feeding roller 22 through the lining beam side pulling cylinder 21 , and then use the feed extract...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap