Sheet counting and arranging machine and working method thereof

A chip counting machine and working method technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of low chip counting accuracy, high production cost, low production efficiency, etc., and achieve high chip counting accuracy , Saving production space and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

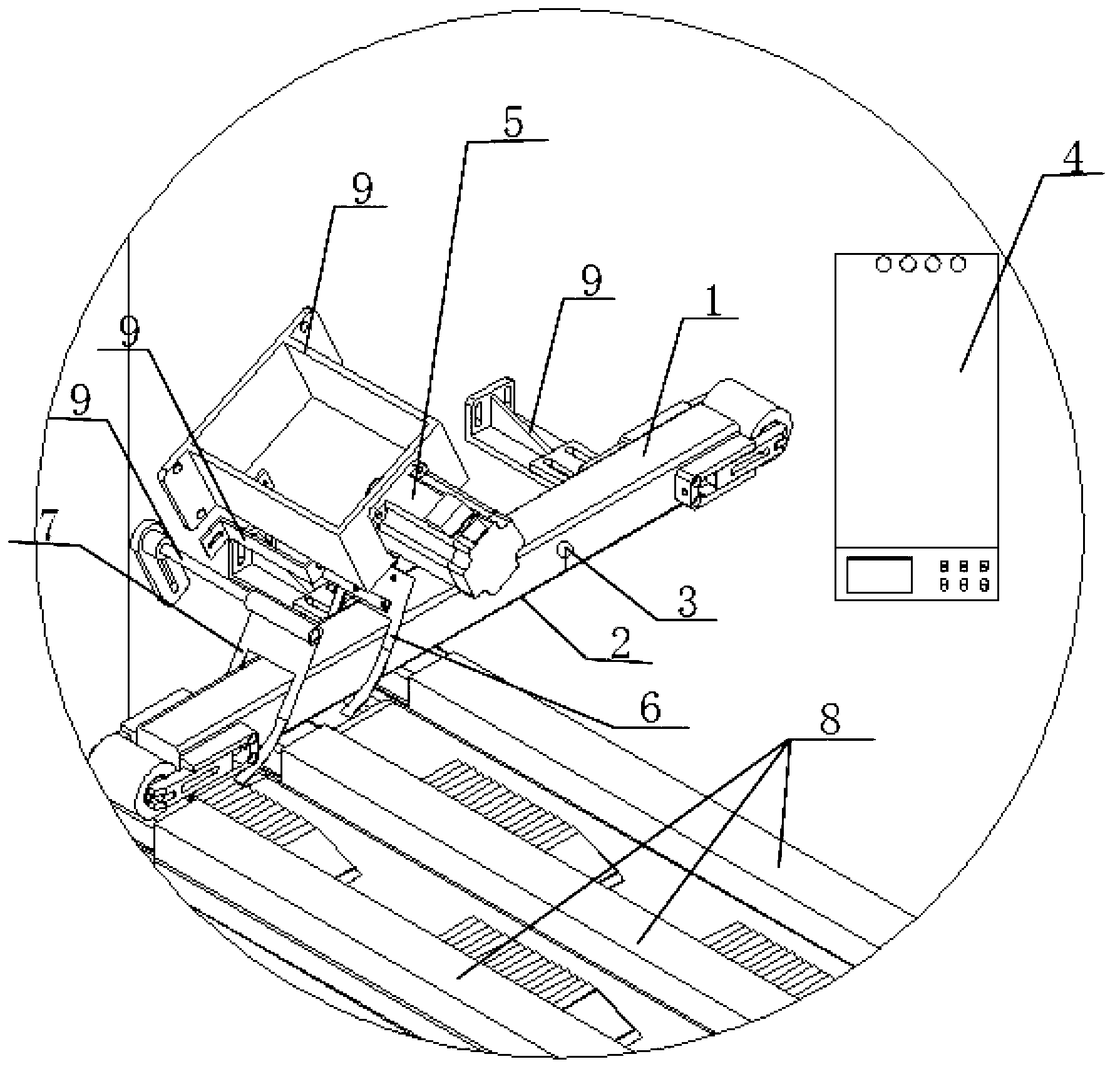

[0020] A specific embodiment of the present invention is a sheet counting and sorting machine, comprising a suction duct 1, a suction belt 2, a photoelectric sensor 3, an industrial programmer 4, a servo motor 5, a movable pick 6, and a fixed stop 7 , double-row conveying line 8, the suction pipe 1 is fixed on the frame wallboard through the bracket 9, the suction belt 2 is set on the suction pipe 1, the photoelectric sensor 3 is arranged on the suction pipe 1, and the photoelectric sensor 3 is located on the On one side of the servo motor 5, the servo motor 5 is fixed on the frame wallboard through the brac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap