Small cigarette packet sealing tag gumming machine

A technology for pasting machines and cigarette packs, applied in packaging and other directions, can solve the problems of inability to achieve anti-counterfeiting, inability to guarantee product quality, corporate waste, etc., and achieve the effect of good anti-counterfeiting, high degree of automation, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

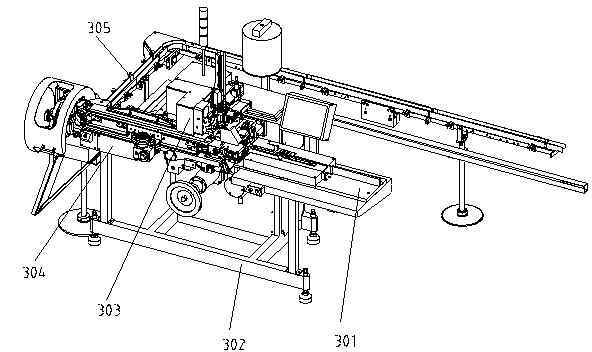

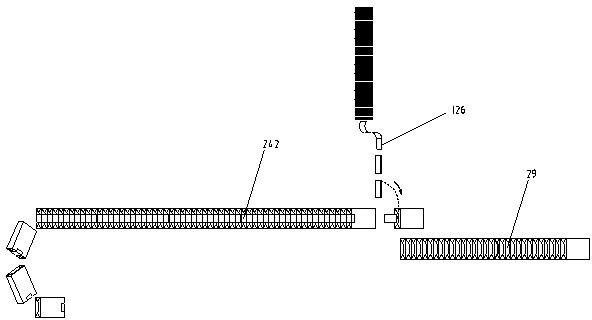

[0042] like Figure 1-28 A cigarette packet seal sticking machine shown in the figure includes a cigarette pack entrance conveying mechanism 301, a cigarette pack lifting, forward pushing, and seal sticking mechanism 302, a seal library and a seal pick-up, transfer, glue application, positioning, and delivery Mechanism 303 , drying and transporting mechanism 304 for cigarette bales after sticking seals, and conveying belt 305 for finished product export cigarette bales.

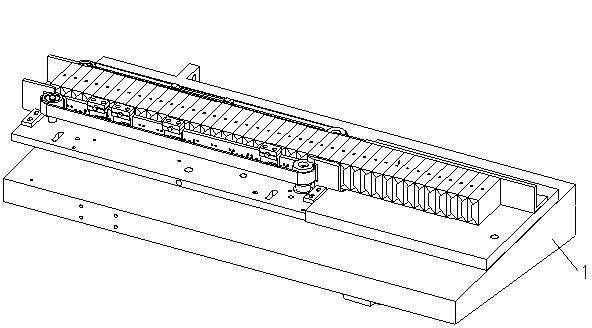

[0043] Cigarette packet entrance conveying mechanism 301 (referring to Figure 3-6) including the entrance frame body 1 and the entrance motor 2 under the entrance frame body, the entrance motor base 3, the entrance motor drive pulley 4, the shaft seat 1 5, the shaft seat 2 6, the toothed pulley 1 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com