Knitwear rolling and inspecting machine

A technology of material rolling and machine inspection, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of difficulty in ensuring the quality of rope-shaped curling, stripping and flattening, affecting the production process, and waste of fabrics, etc., to achieve The effect of saving manpower input and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

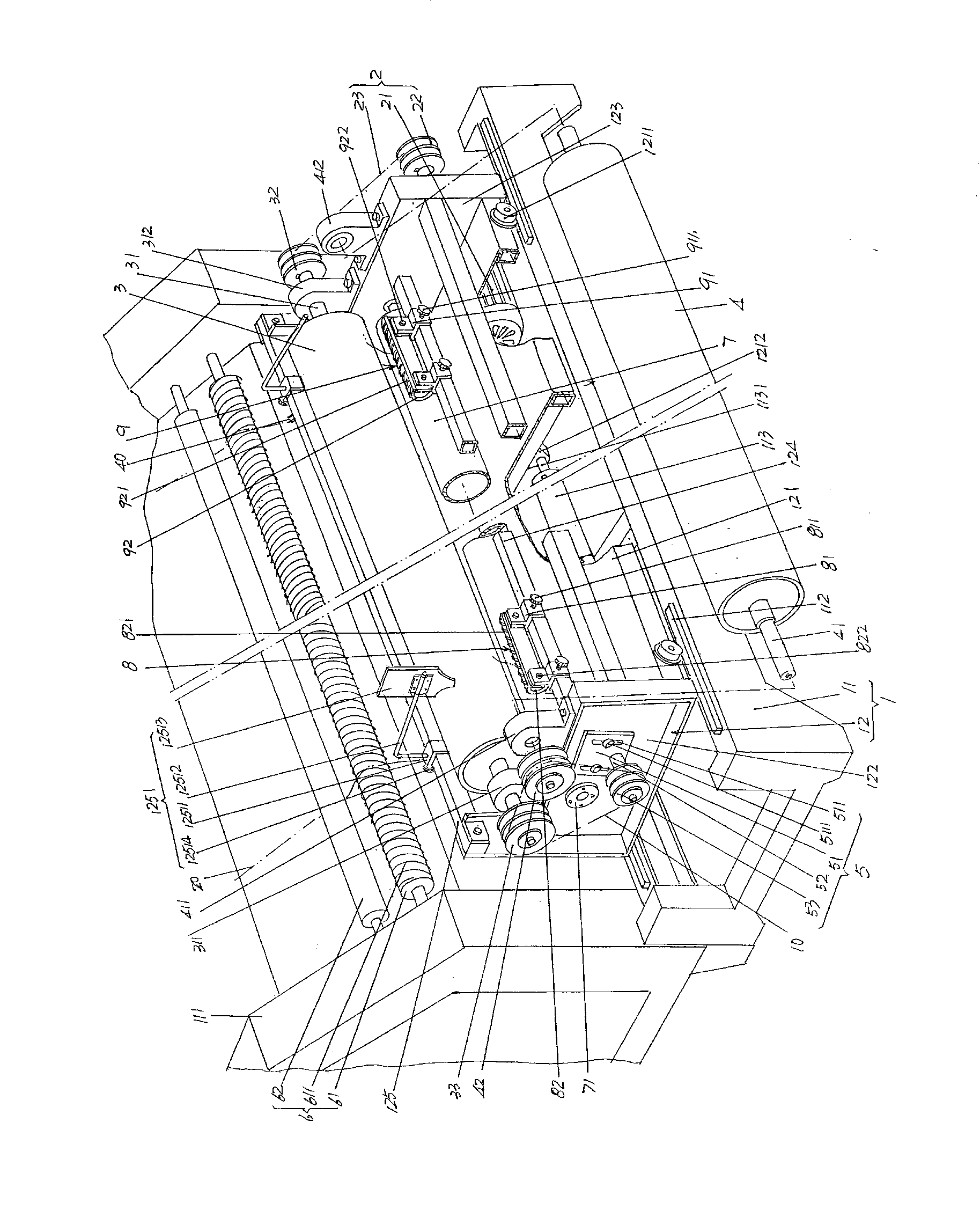

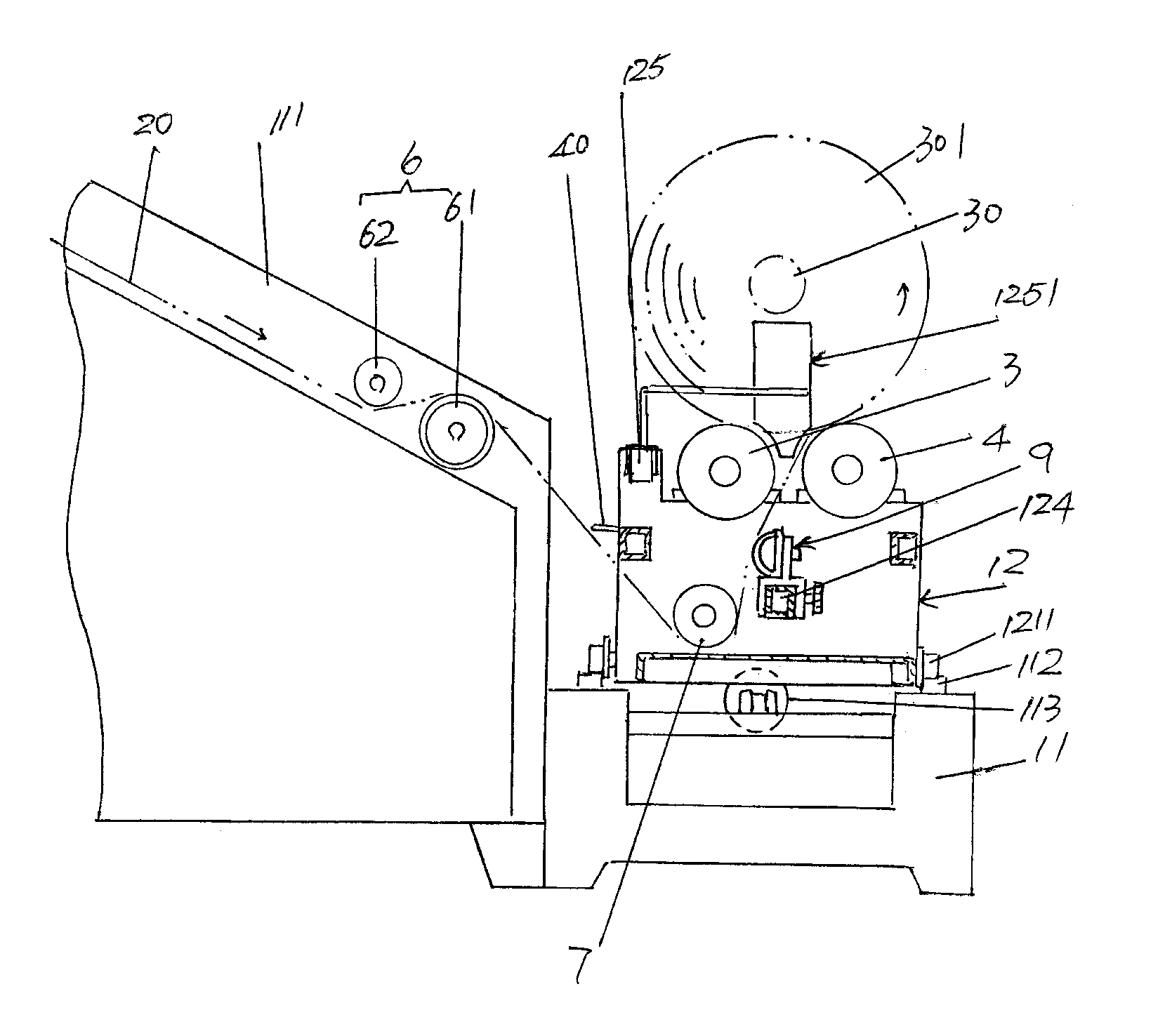

[0023] See figure 1 , a cloth roll frame 1 is given, the cloth roll frame 1 includes a base 11 and a mobile trolley 12, the base 11 is set on the floor of the place of use, and a lengthwise direction of the base 11 side figure 1 The rear side of the shown position state is fixed with a cloth guide mechanism support 111, and a guide rail 112 is respectively fixed on the upper part of the corresponding two sides of the length direction of the base 11, and the mobile trolley 12 is movably arranged on the base 11. set on the guide rail 112. In order to avoid unnecessary waste of material, because the left and right movement range of the mobile trolley 12 on the base 11 is relatively small, only a section of guide rail is respectively fixed at the two ends of the upper part of the corresponding two sides in the length direction of the base 11. 112.

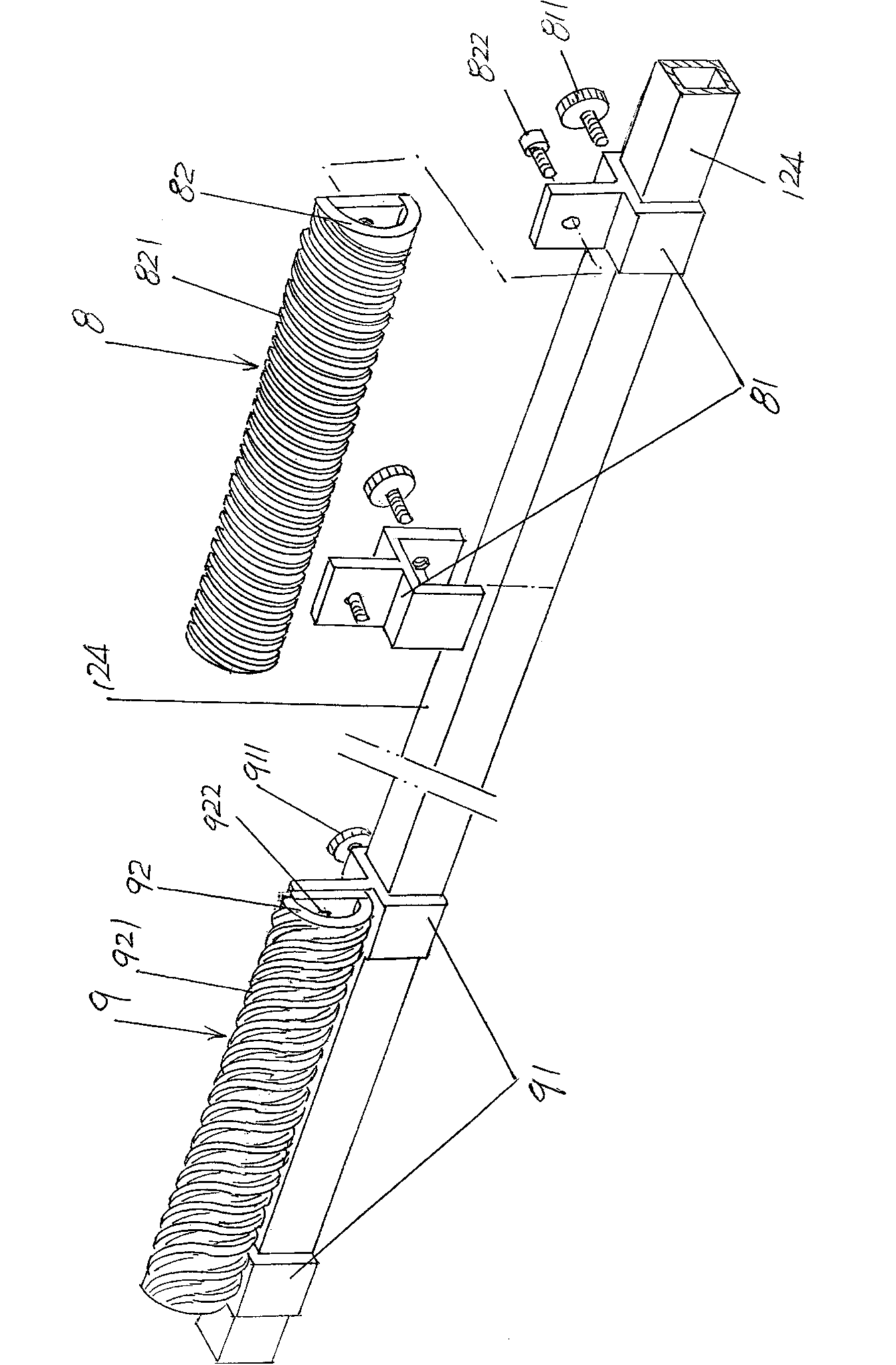

[0024] The aforementioned mobile trolley 12 comprises a trolley base 121, left and right wall panels 122, 123 and a fixed bar 124 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com