Automatic wire binding machine for electric power engineering

A technology of electric power engineering and wire binding machine, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc. It can solve the problems of irregular binding coils, time-consuming and laborious, unsightly, etc., and achieve neat and beautiful binding wires, Improve work efficiency and solve time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

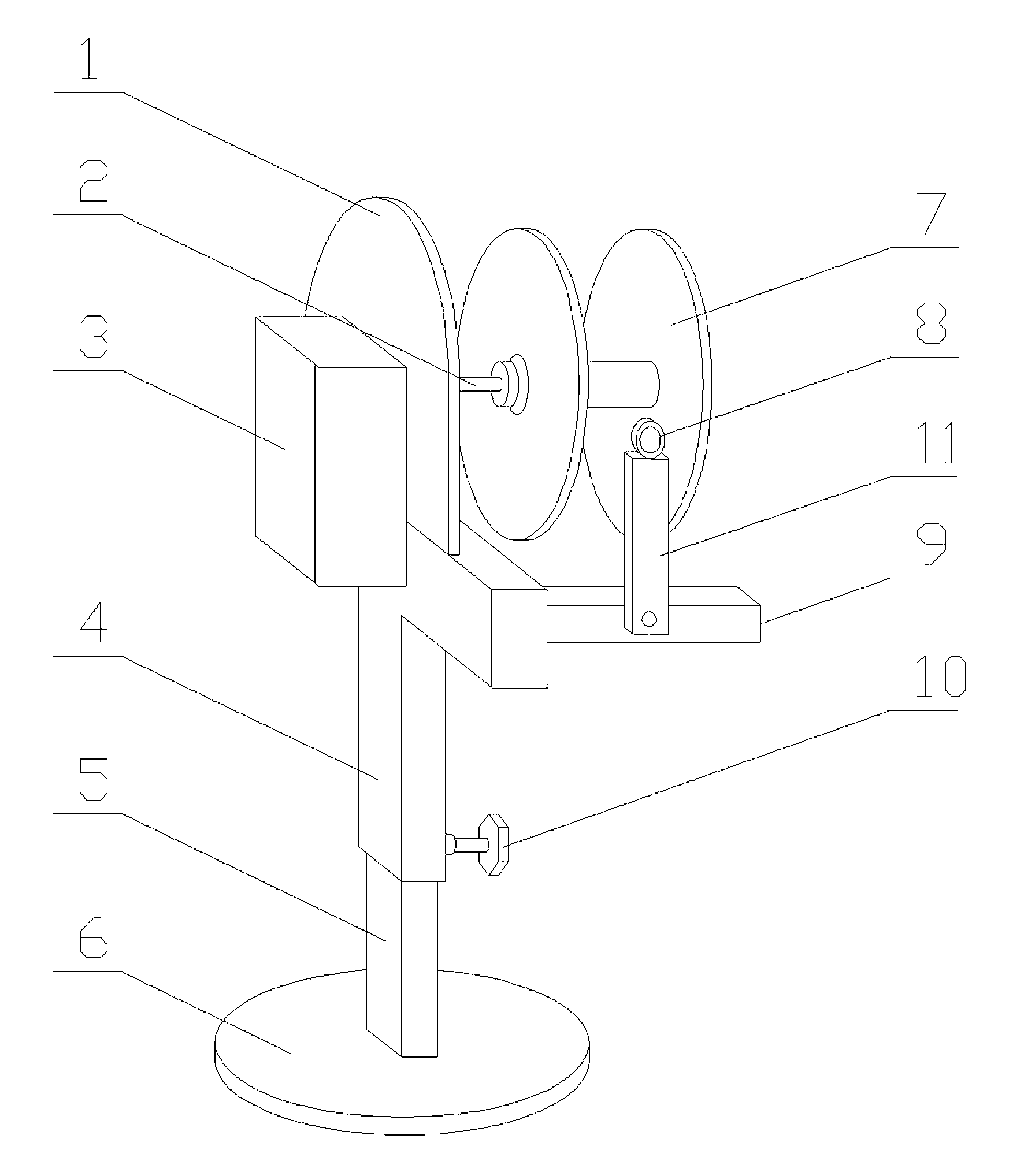

[0010] as attached figure 1 Shown is a specific embodiment of the present invention, the present invention comprises base 6, support frame 4, the bobbin 7 that is fixed on the support frame 4, vertical board 1 and the motor 3 that is fixed on the support frame 4, described motor 3 passes The rotating shaft 2 arranged on the vertical plate 1 is connected with the spool 7; the support frame 4 is provided with a crossbeam 9, and the crossbeam 9 is provided with a pillar 11, and the pillar 11 is hinged with the crossbeam 9, and the pillar 11 is provided with There is a collar 8; the base 6 is provided with a connecting pipe 5, the supporting frame 4 is sleeved on the connecting pipe 5, and the supporting frame 4 is provided with fastening bolts 10. When using the present invention, the base 6 is placed on the ground, since the support frame 4 is sleeved on the connecting pipe 5, the height of the support frame 4 can be adjusted first, and then fixed by the fastening bolt 10 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com