Valve-pot combining type grain slag output method and device

A technology for water slag and water output, which is applied in the field of outputting metallurgical slag, and can solve problems such as no delivery method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

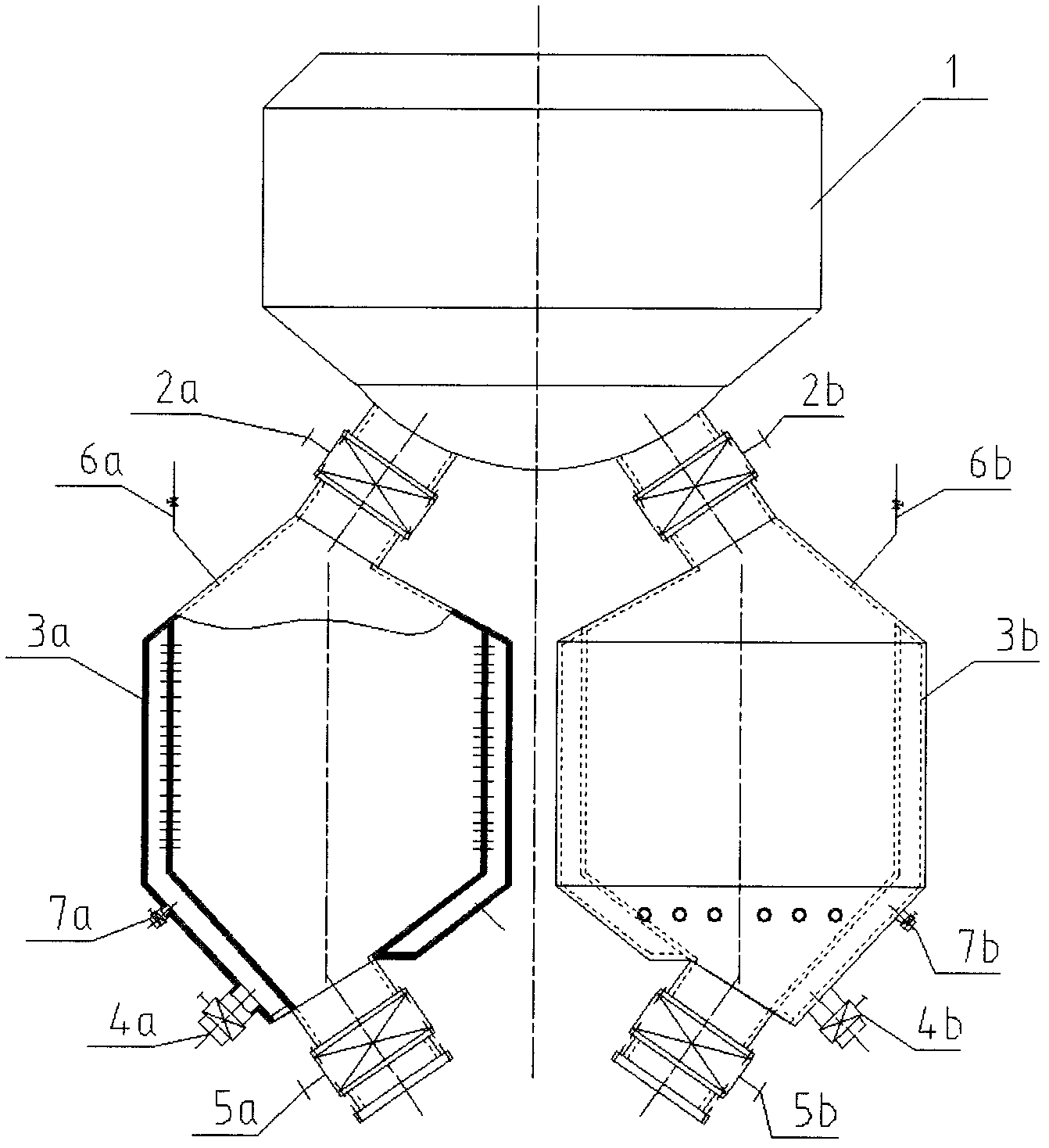

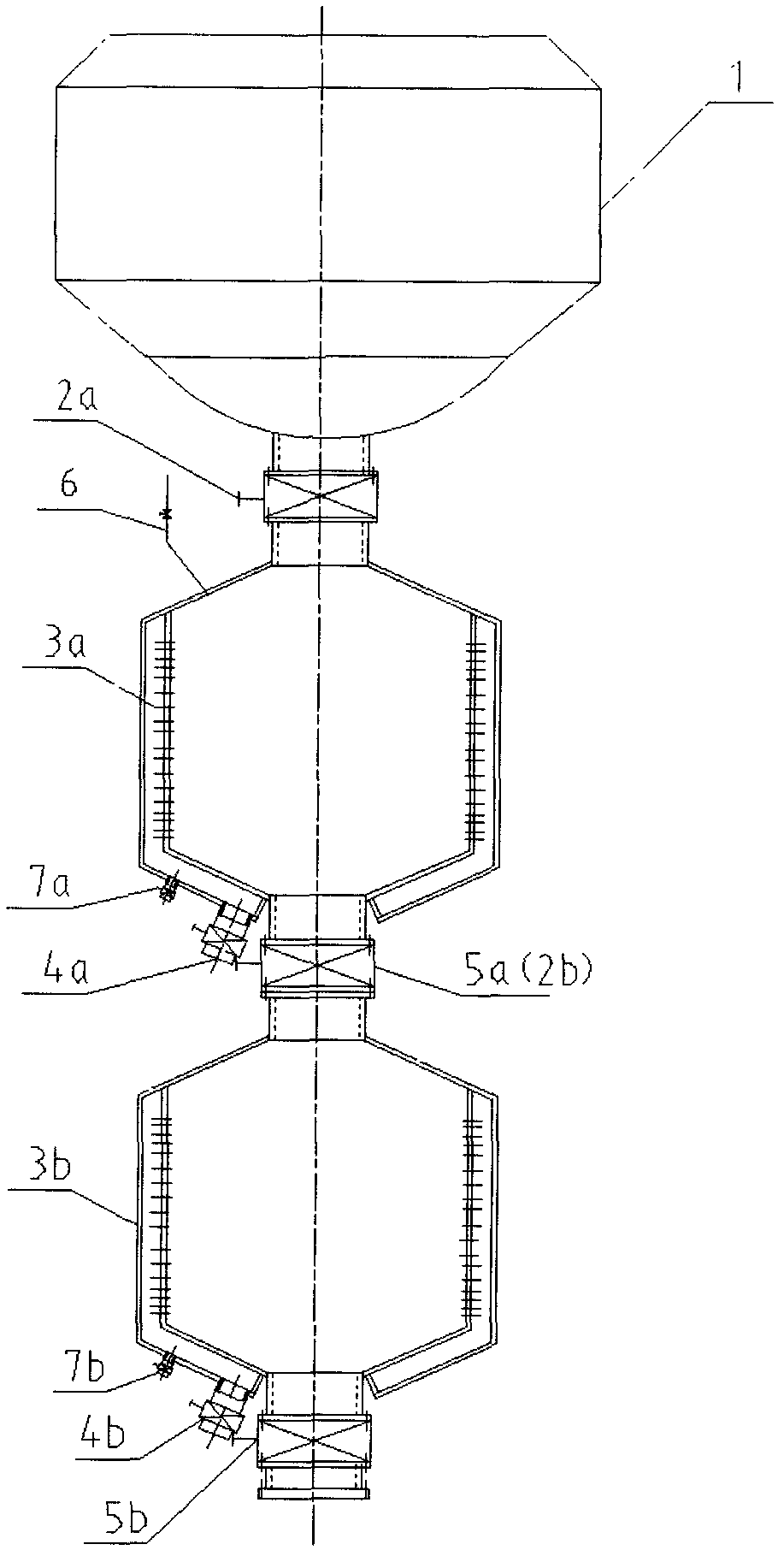

[0023] figure 1 The working process of merging tanks is as follows:

[0024] Before slag discharge: the tank 1 of the slag treatment device is sealed, the slag treatment device has been working and produces a certain amount of water slag or dry slag, and the valves 2 and 5 of the tank 3 are in the closed position.

[0025] Slag discharge: tank a#, open the slag discharge valve 2a, the slag flows into the tank 3a, close the slag discharge valve 2a after the tank is full of slag, open the drain pipe valve 4a or the pressure relief pipe valve 6a to discharge water or release pressure, wait for water, gas After the release, close the valve 4a or 6a, open the slag discharge valve 5a to discharge the slag, close the slag discharge valve 5a after the slag is discharged, open the pressure charging pipe 6a to pressurize the tank 3, and close the pressure after the pressure of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com