Hydrogen storage alloys for metal hydride-high pressure composite hydrogen storage

A hydrogen storage alloy and hydride technology, applied in the field of alloys, can solve problems such as poor activation performance, low effective hydrogen storage capacity, and inability to meet the application requirements of metal hydride-high pressure composite hydrogen storage containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Design a hydrogen storage alloy whose chemical formula is Ti 1.02 Cr 1.2 Fe 0.6 mn 0.2 B 0.01 , Calculate the addition amount of each raw material according to the chemical formula. The raw material purity of Ti, Cr, Fe, Mn and B all reach above 99%. The above-mentioned raw materials are weighed according to the calculated addition amount after being cleaned and dried, and an additional 3% weight of Mn is added according to the proportioning amount. Put the weighed sample in the water-cooled copper crucible of the magnetic levitation furnace. After evacuating to a vacuum degree of 1.02 Cr 1.2 Fe 0.6 mn 0.2 B 0.01 match.

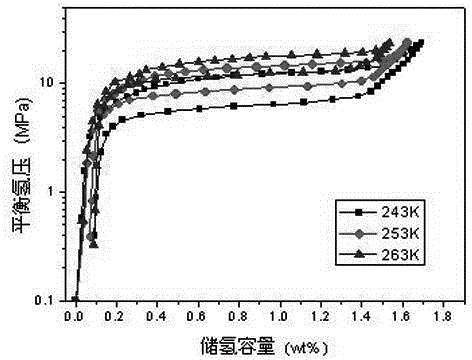

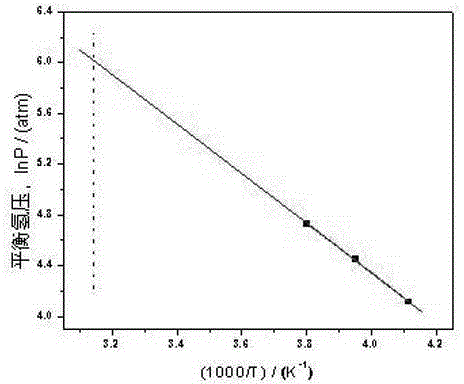

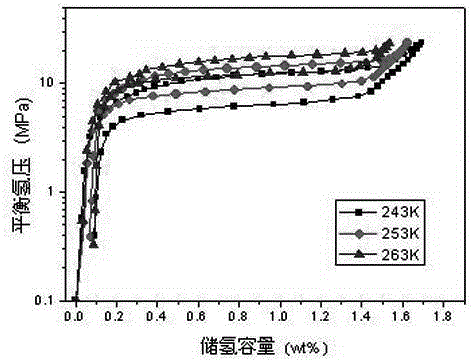

[0034] The prepared hydrogen storage alloy ingot was crushed into particles with a particle size of less than 200 microns, and then loaded into a reactor to measure the hydrogen storage performance. The hydrogen storage alloy is first evacuated under the heating condition of 400°C for 30 minutes, and then filled with high-pressure hydrogen ga...

Embodiment 2

[0036] The design chemical formula is Ti 1.01 Cr 1.1 Fe 0.6 mn 0.3 B 0.01 The hydrogen storage alloy, according to the chemical formula to calculate the addition of each raw material. The raw material purity of Ti, Cr, Fe, Mn and B all reach above 99%. The above-mentioned raw materials are weighed according to the calculated addition amount after being cleaned and dried, and an additional 3% weight of Mn is added according to the proportioning amount. Put the weighed sample in the water-cooled copper crucible of the magnetic levitation furnace. After evacuating to a vacuum of 1.01 Cr 1.1 Fe 0.6 mn 0.3 B 0.01 match.

[0037] The prepared hydrogen storage alloy ingot was crushed into particles with a particle size of less than 200 microns, and then loaded into a reactor to measure the hydrogen storage performance. The hydrogen storage alloy is first evacuated at 400°C for 30 minutes, and then filled with high-pressure hydrogen. The alloy is easy to absorb hydrogen and ...

Embodiment 3

[0039] The design chemical formula is Ti 1.02 Cr 1.1 Fe 0.6 mn 0.3 B 0.01 The hydrogen storage alloy, according to the chemical formula to calculate the addition of each raw material. The raw material purity of Ti, Cr, Fe, Mn and B all reach above 99%. The above-mentioned raw materials are weighed according to the calculated addition amount after being cleaned and dried, and an additional 3% weight of Mn is added according to the proportioning amount. Put the weighed sample in the water-cooled copper crucible of the magnetic levitation furnace. After evacuating to a vacuum of 1.02 Cr 1.1 Fe 0.6 mn 0.3 B 0.01 match.

[0040] The prepared hydrogen storage alloy ingot was crushed into particles with a particle size of less than 200 microns, and then loaded into a reactor to measure the hydrogen storage performance. The hydrogen storage alloy is first evacuated under the heating condition of 400°C for 30 minutes, and then filled with high-pressure hydrogen gas. The alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com