Sealed Liquid Pressure Differential Layered Settlement Gauge and Its Embedding and Measurement Method

A layered subsidence meter and measurement method technology, which is applied in the field of land subsidence detection, can solve the problems of large measurement errors, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

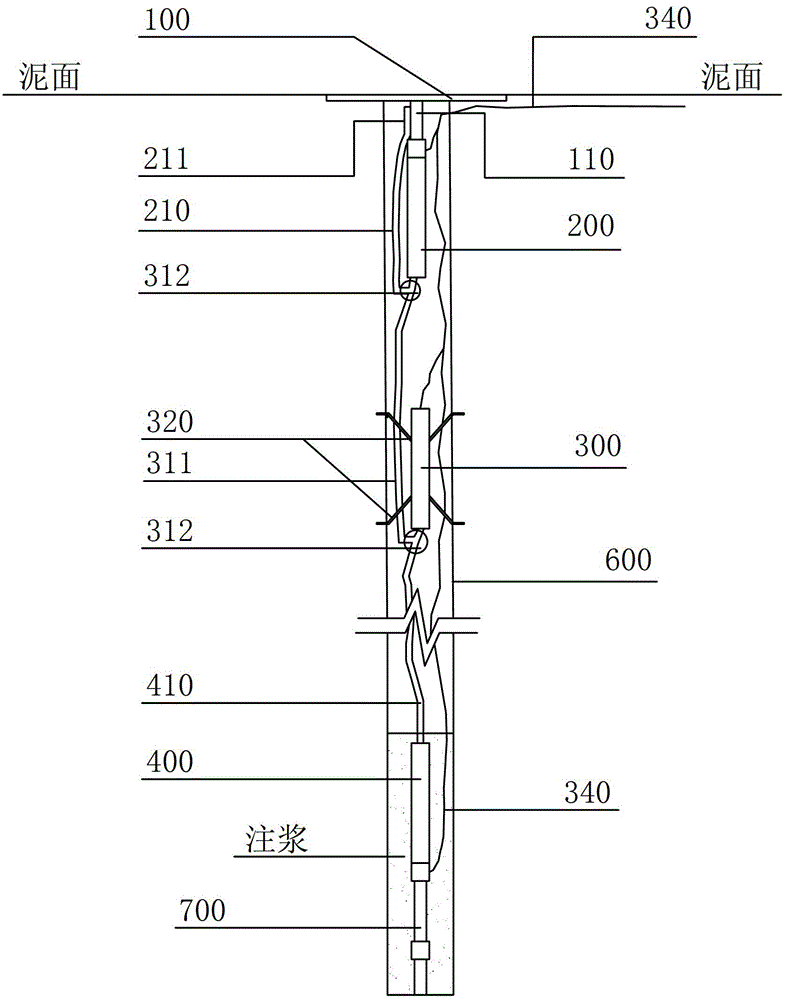

[0067] This embodiment provides a sealed liquid differential pressure layered settlement meter, such as figure 1 As shown, the sealed liquid differential pressure layered settlement meter includes: a settling plate 100, a top hydraulic sensor 200, a middle hydraulic sensor group 300, a bottom hydraulic sensor 400, and an auxiliary rod 500 (see Figure 5 ), the drilling protection casing 600, and the bottom fixing device 700.

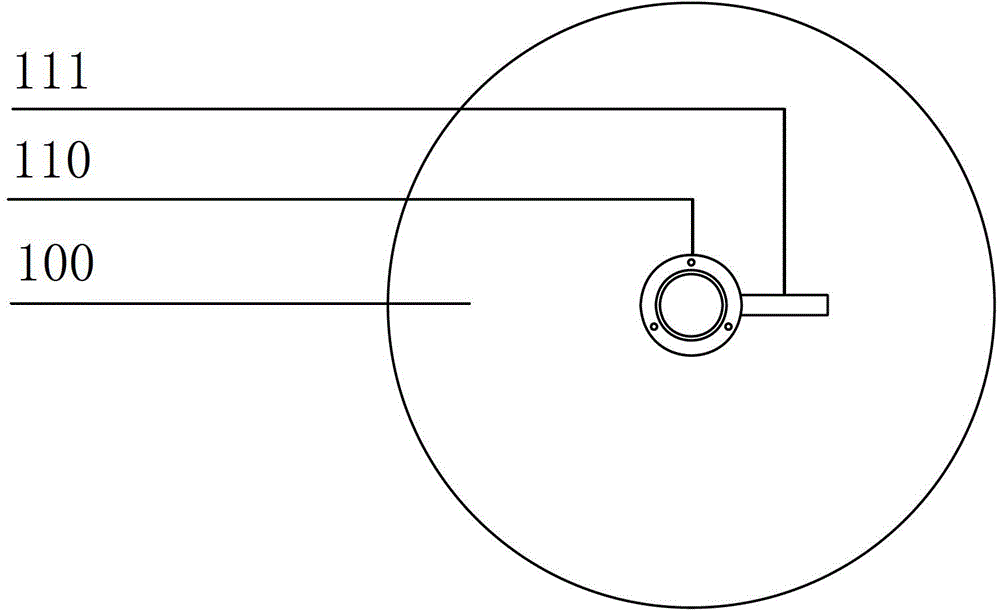

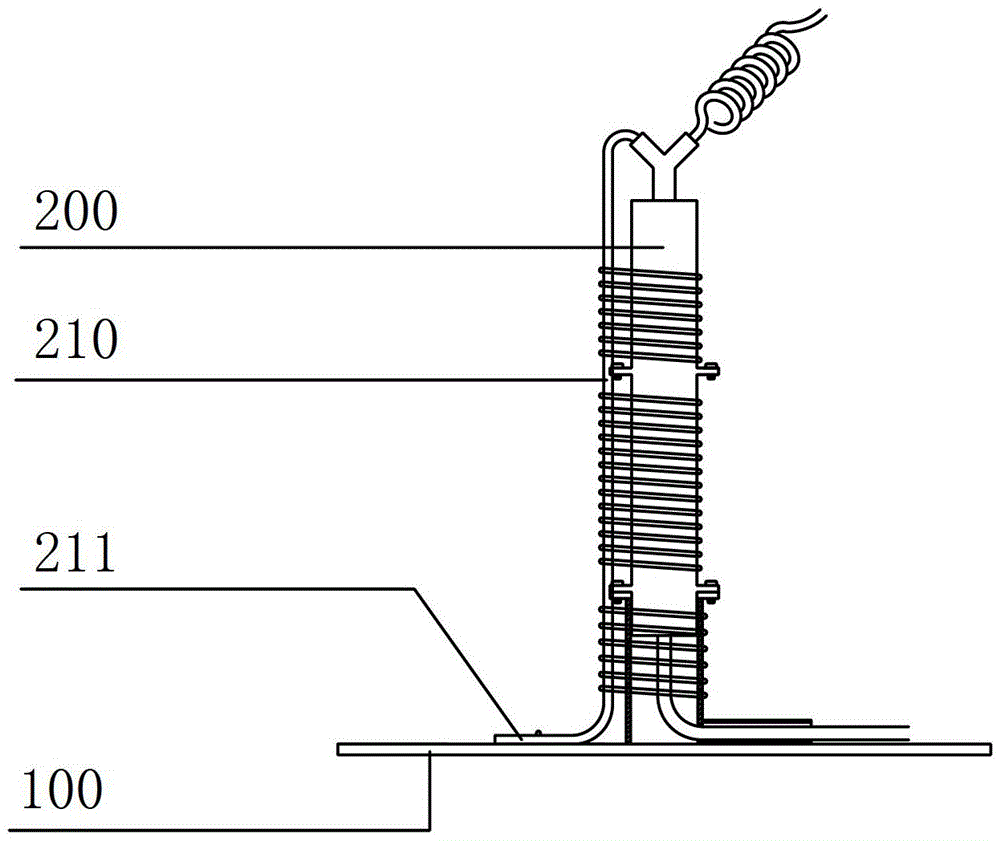

[0068] Such as Figure 2a and Figure 2b As shown, the top hydraulic pressure sensor 200 is fixedly installed under the settling plate 100 through the flange 110 . The top hydraulic pressure sensor 200 includes a liquid tube 210 with a sealed orifice. There is a certain length of gas section at the top of the orifice-sealed liquid pipe 210 . The nozzle 211 of the liquid pipe 210 is vertically fixed on the flange 110 . The flange 110 is provided with a threading pipe 111; the signal cable 220 of the top hydraulic sensor 200, the signal cable 340 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com