Integral plug-in type hand-operated direction valve

A manual reversing valve and plug-in technology, which is applied in the direction of mining equipment, earthwork drilling, pillars/brackets, etc., to achieve the effects of reasonable design of the movement track of parts, convenient and quick replacement, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

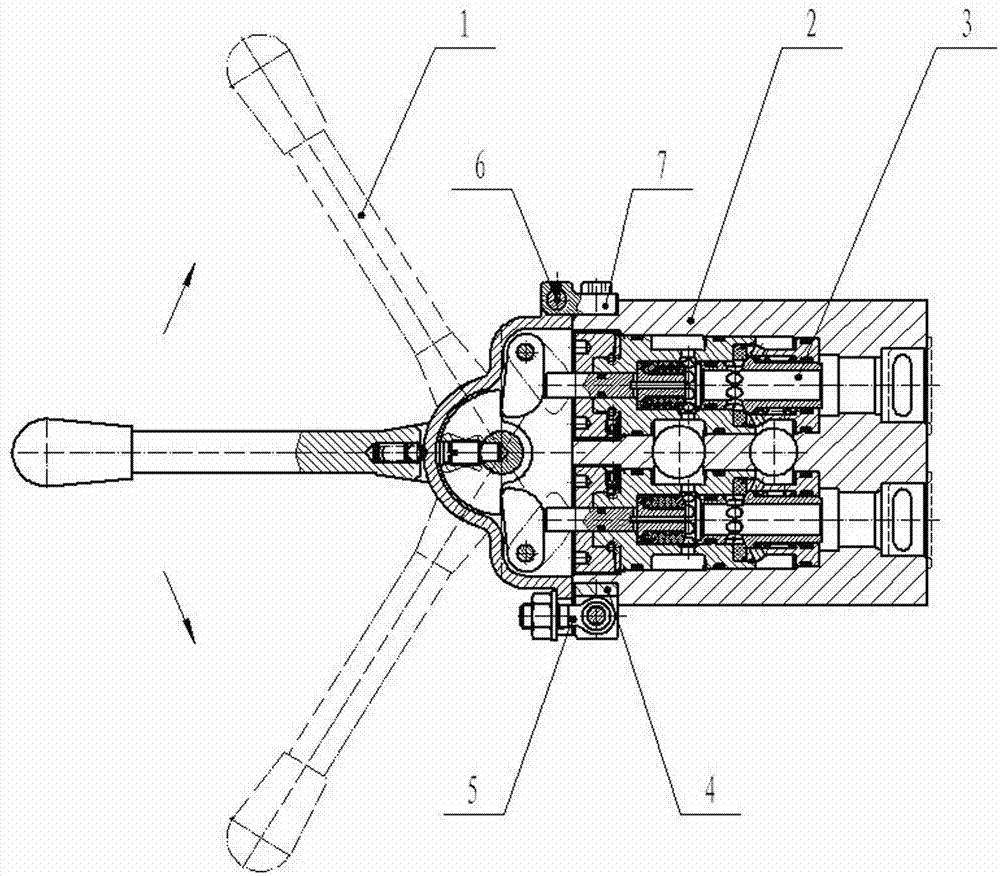

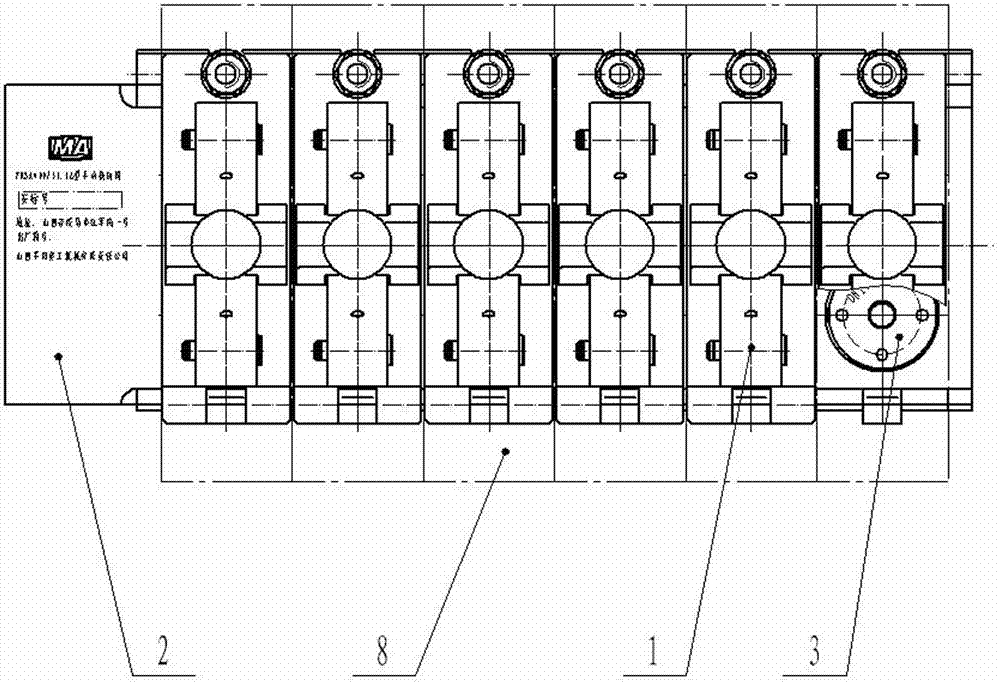

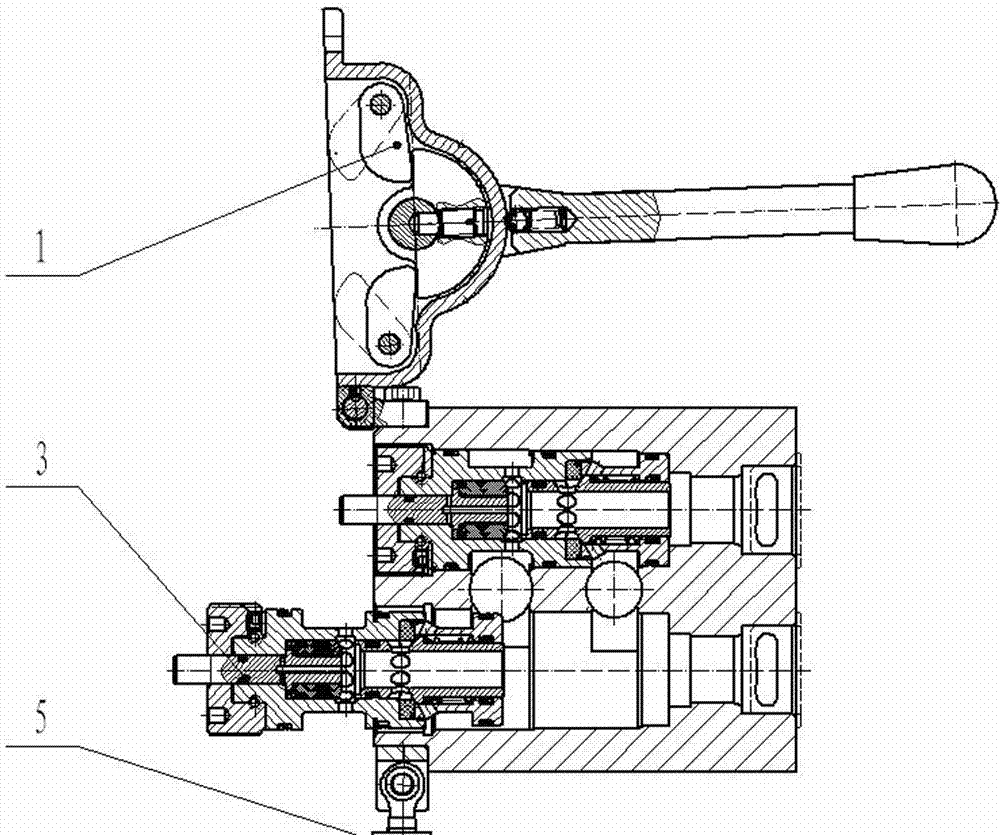

[0016] Such as figure 1 , an integral cartridge type manual reversing valve, which includes an operating mechanism 1, a valve body assembly 2, a valve core assembly 3, a pressure block 4, a swing bolt 5, a pin shaft 6, a hinge seat 7 and a control unit 8. The upper end of the mechanism 1 and the valve body assembly 2 is hinged with the hinge seat 7 through the pin shaft 6, the hinge seat 7 is connected with the upper end of the valve body assembly 2 through bolts, the pressure block 4 is arranged at the lower end of the valve body assembly 2, the operating mechanism 1 and the valve body assembly The lower end of 2 is pressed and connected by the joint bolt 5, the valve core assembly 3 is set in the valve body assembly 2, the valve body assembly 2 and the valve core assembly 3 are threaded through the inner cavity of the valve body assembly 2, and the control unit 8 is controlled by the operating mechanism 1 It is composed of a pair of valve core assemblies (3), and the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com