Method for increasing permeability of low-permeability coal seam by means of deep-hole directional pre-splitting blasting

A technology of pre-splitting blasting and low air permeability, which is applied in the direction of earthwork drilling, gas discharge, mining fluid, etc. It can solve the problems affecting the coal seam gas extraction rate and extraction effect, and the coal seam low air permeability, so as to prevent gas disaster accidents The effect of occurrence, improvement of air permeability, and high gas drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The method for increasing permeability of low-permeability coal seam by deep hole directional pre-splitting blasting of the present invention, its preferred embodiment is:

[0020] Include steps:

[0021] First of all, using conventional operation methods, construct large-diameter blasting holes in high-gas and low-permeability coal seams;

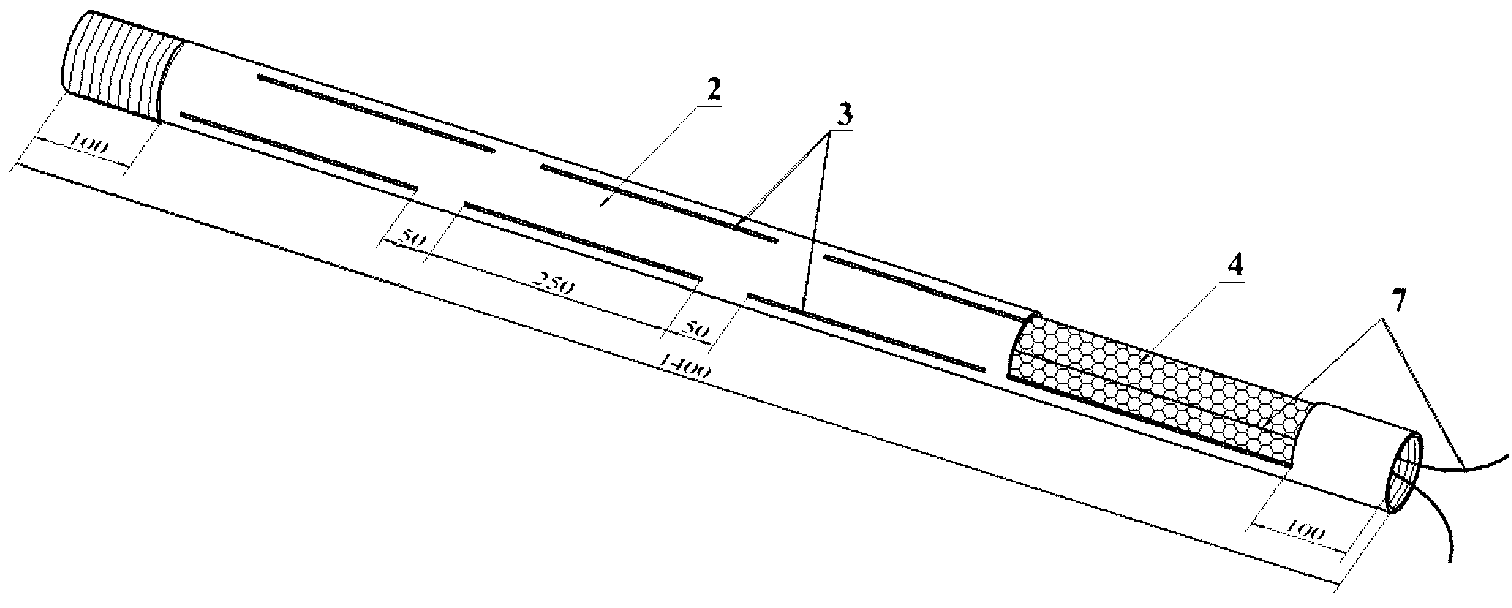

[0022] Then, the four-way vertical slit pipe is used as the blasting charge pipe and the water bag pipe, and the four positions of 0°, 90°, 180° and 270° in the circumferential direction of the four-way vertical slit pipe are respectively provided with longitudinal slits. seam

[0023] Afterwards, the four-way vertical slotted tube with the charge roll and the four-way vertical slotted tube with the water bag are arranged at intervals to fill the large-diameter blasting hole with explosives, and the explosives are indexed through the double detonator. , to complete the blasting and anti-reflection operation on low-permeable thick ...

specific Embodiment

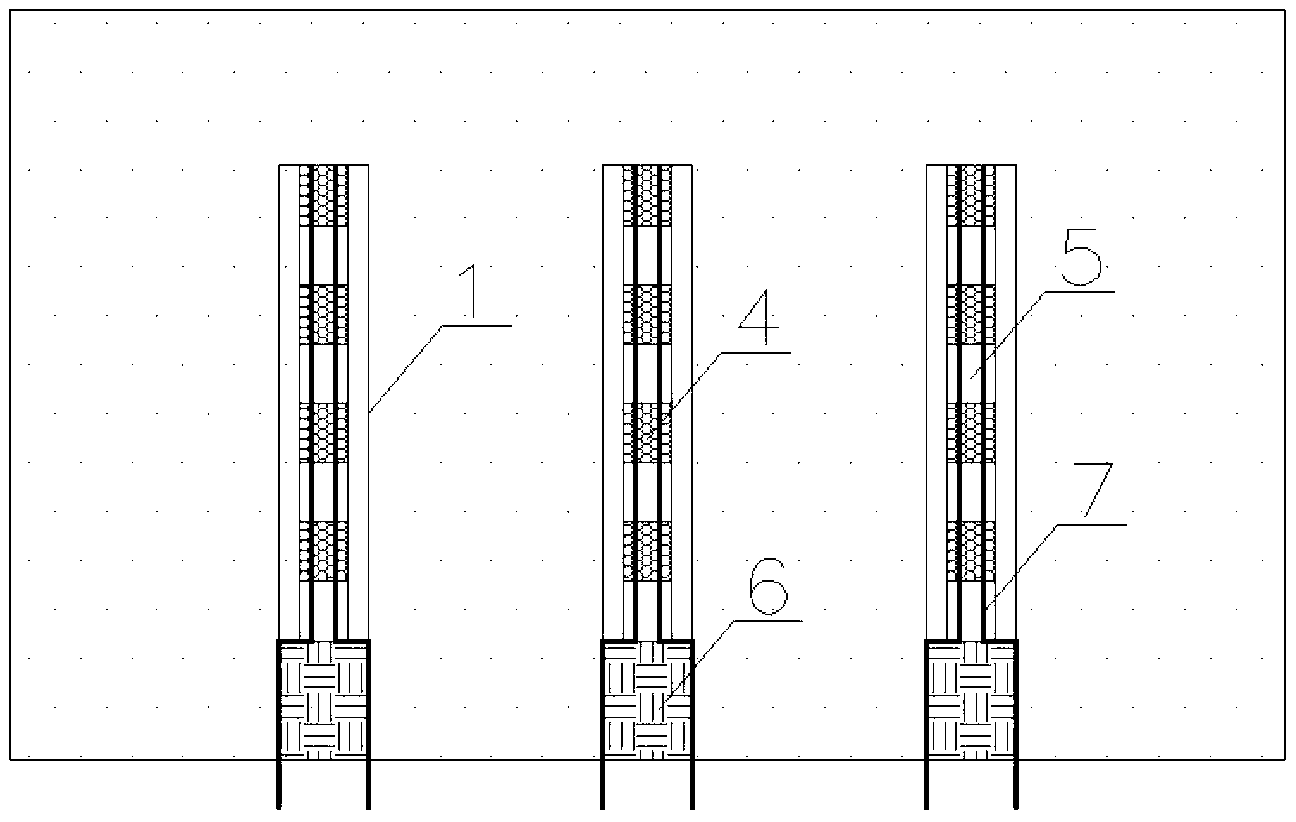

[0041] A method for increasing permeability of low-permeable coal seams in deep-hole directional pre-splitting blasting combined with the four-way vertically slit pipe 2 and the drug roll 4 and the four-way vertically slit pipe 2 and the water bag 5 for charge at intervals.

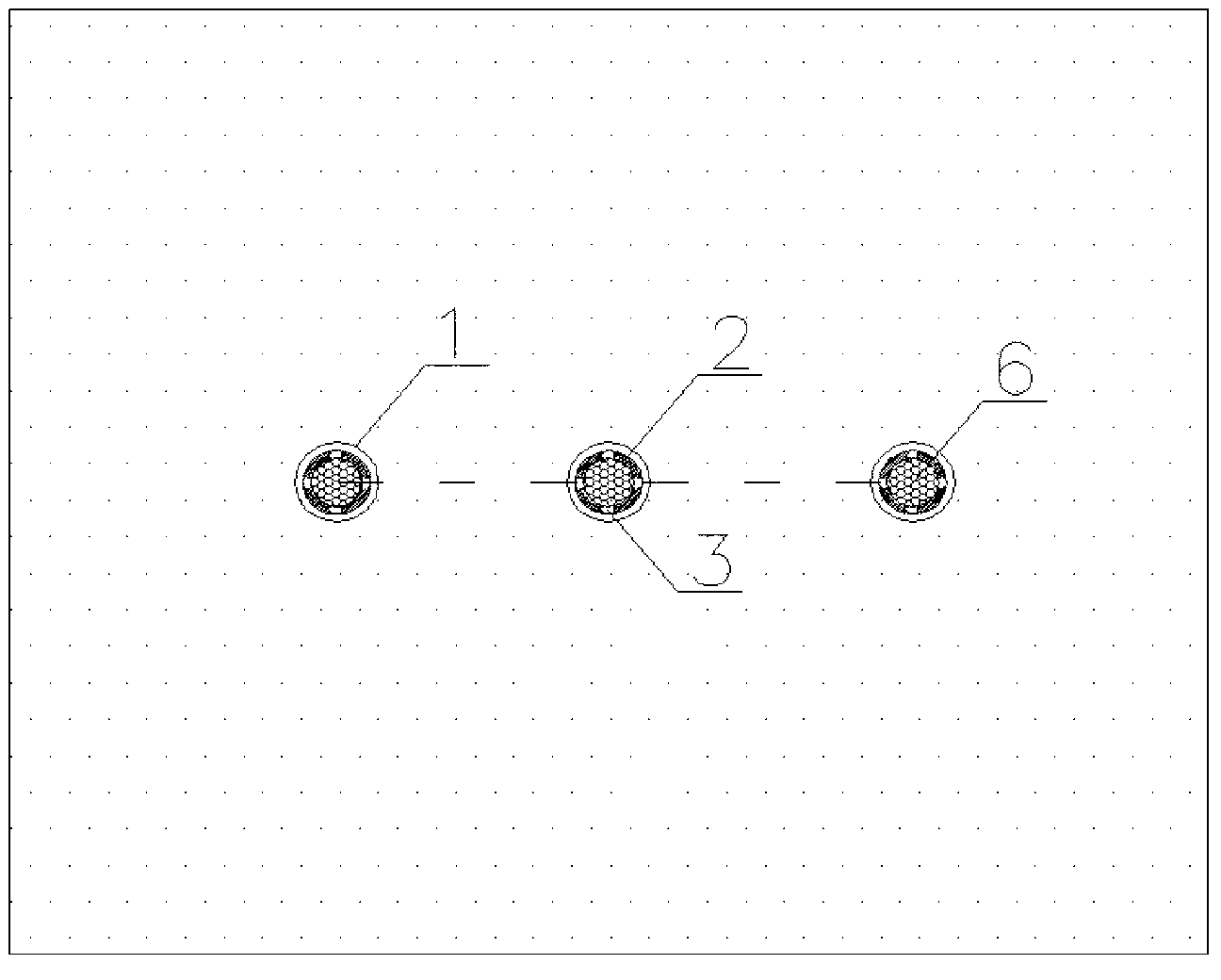

[0042] like figure 1 , figure 2 As shown, taking 3 blastholes as an example, the specific steps include:

[0043] Step 1: Construct large-diameter deep blast holes in the coal seam by adopting conventional operation methods.

[0044] Under normal circumstances, the coal seam is thick and has low air permeability, so the gas exists in the coal seam in the state of adsorption. The construction of deep blast hole 1 can release the gas in the deep coal seam and increase the air permeability of the coal seam, which is beneficial to improve the gas in the thick coal seam. Extraction effect. In general, the diameter of blast hole 1 for large-diameter deep hole blasting is 60-80mm, the depth of blast hole 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com