Liquid fuel strainer assembly

A technology of filter assembly and liquid fuel, which is applied in the direction of liquid fuel feeder, filtration and separation, thin material processing, etc., and can solve the problems of reducing the efficiency of multi-layer structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Those skilled in the art will understand that terms such as "upper", "lower", "upward", "downward", "top", "bottom" and the like are used descriptively to the drawings and do not represent the protection scope of the present invention. limitations, the scope of protection is defined by the appended claims.

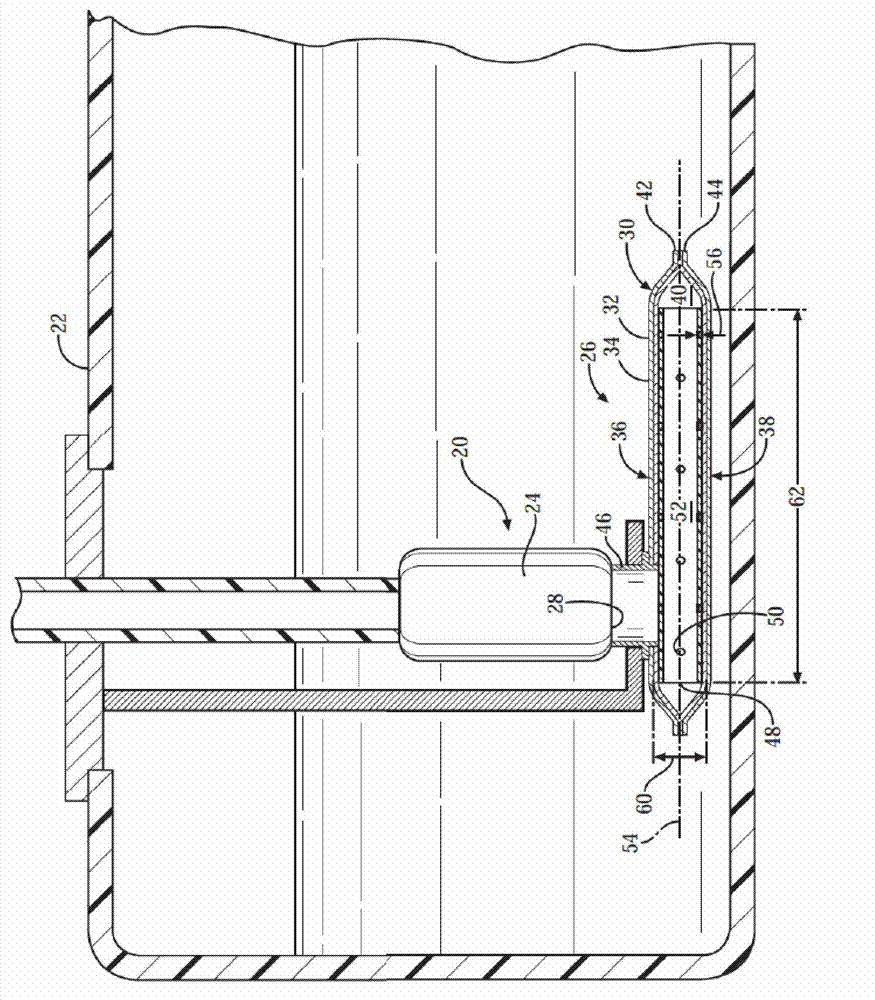

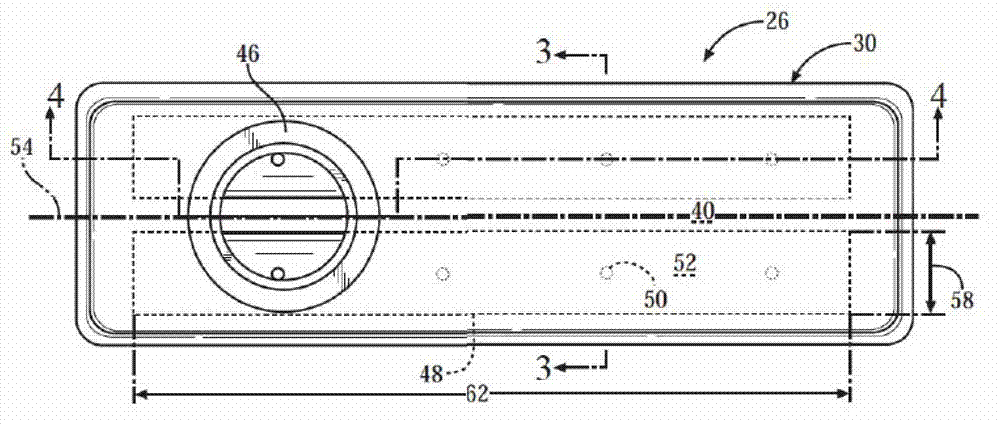

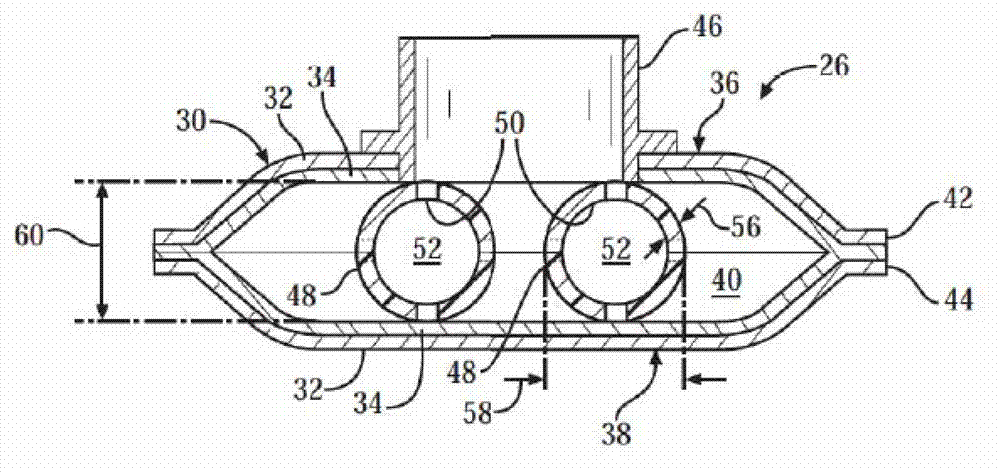

[0012] Referring to the drawings, wherein like reference numerals represent like components throughout the several views, a fuel delivery unit is shown generally at 20 . refer to figure 1 , the fuel delivery unit 20 is disposed inside a fuel tank 22 of the vehicle. The fuel delivery unit 20 includes a fuel pump 24 that circulates fuel from a fuel tank 22 to the engine of the vehicle. To filter or block particulate matter or sediment suspended within fuel delivery unit 20 , fuel delivery unit 20 includes a liquid fuel filter 26 therein. A liquid fuel filter 26 is attached to the fuel pump inlet 28 and filters or collects particulate matter larger than a predefined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com