A Variable Area Gradient Digital Rotary Valve

A variable area and gradient technology, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., to achieve high precision, uniform force, and breakthrough processing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

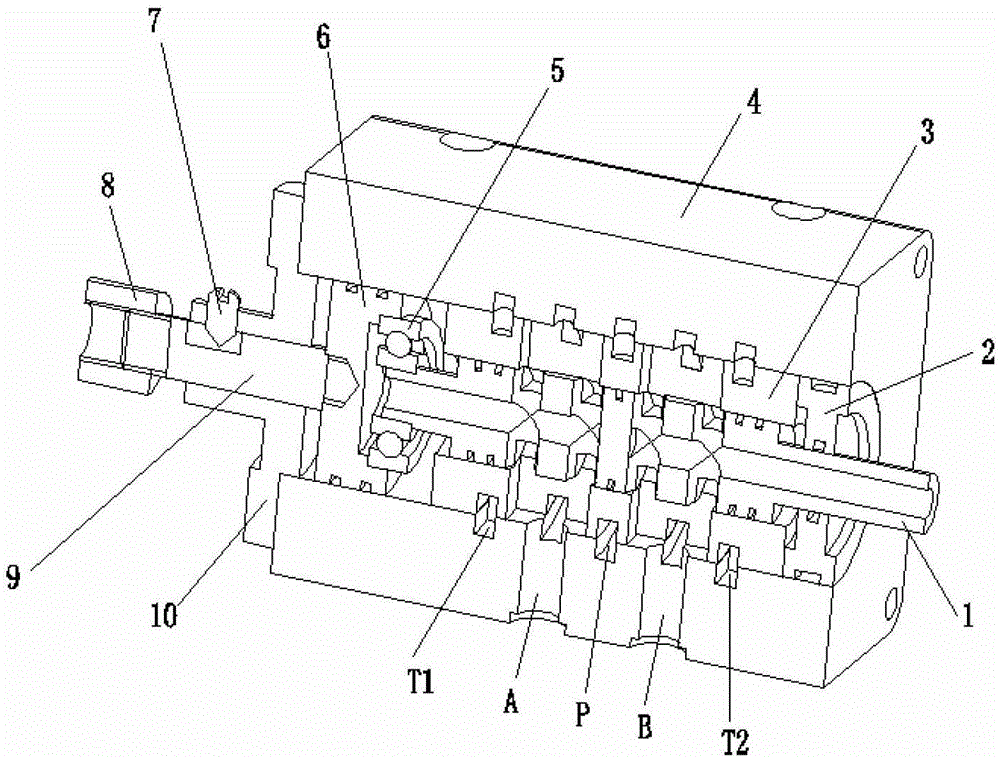

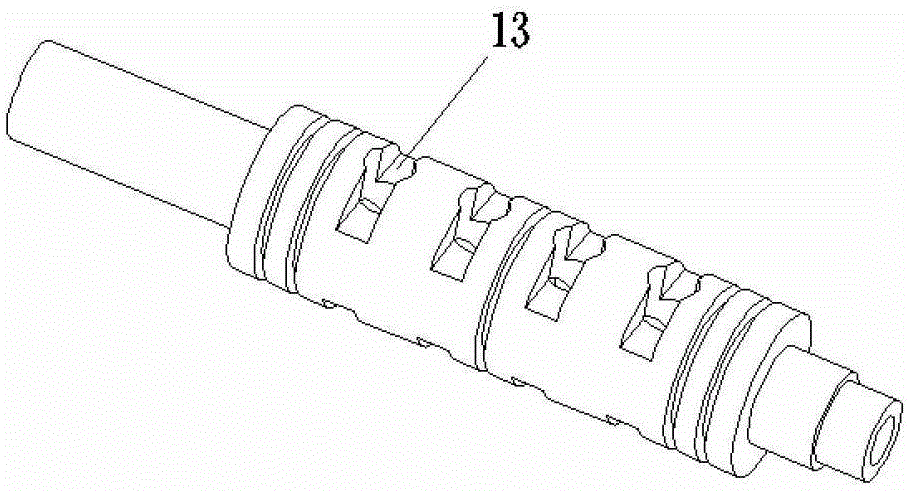

[0019] as attached Figure 1~4 As shown, the five annular grooves of the valve sleeve 3 nested in the inner cavity of the valve body 4 correspond to the positions of the annular grooves in the inner cavity of the valve body 4 one by one, and the five annular grooves in the inner cavity of the valve body 4 are respectively connected to the left Oil port T1, left working oil port A, oil inlet P, right working oil port B, right return oil port T2.

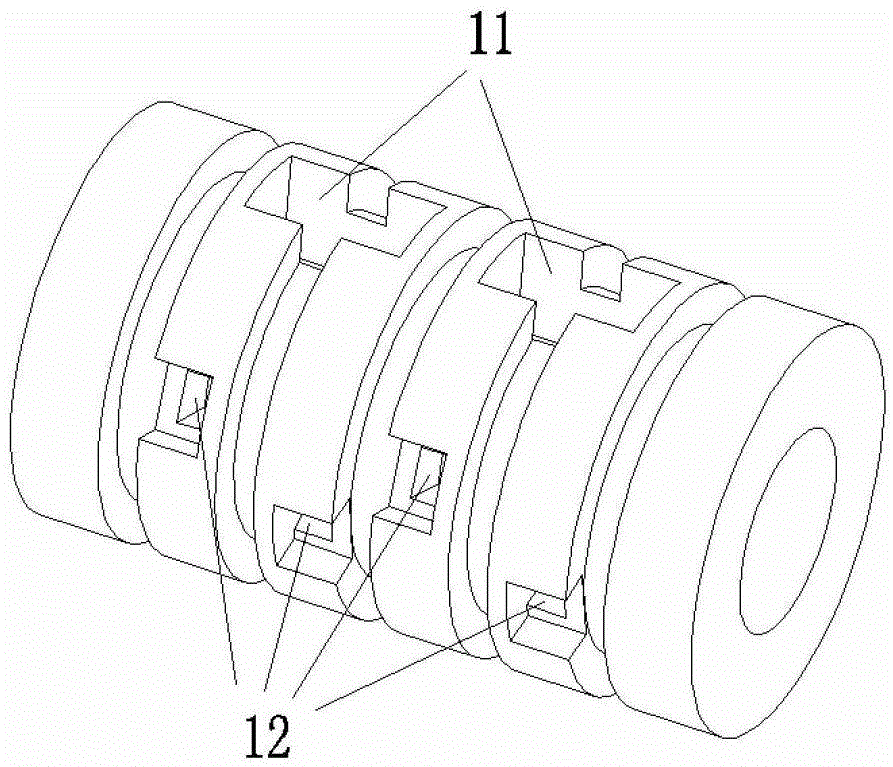

[0020] The four groups of rectangular control valve ports 12 processed on the valve sleeve 3, from left to right, the first group of valve ports communicate with the left oil return port T1, the second and third groups of valve ports communicate with the oil inlet P, and the fourth group of valve ports It communicates with the right oil return port T2. Two groups of oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com