Inlaid valve element and manufacturing process thereof

An inlaid and spool technology, which is applied in the direction of manufacturing tools, cores, valve devices, etc., can solve the problems of increased resistance to the up and down movement of the spool, poor precision of the chute, rough surface, etc., to save production costs and service life Good effect of improving and anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. rear.

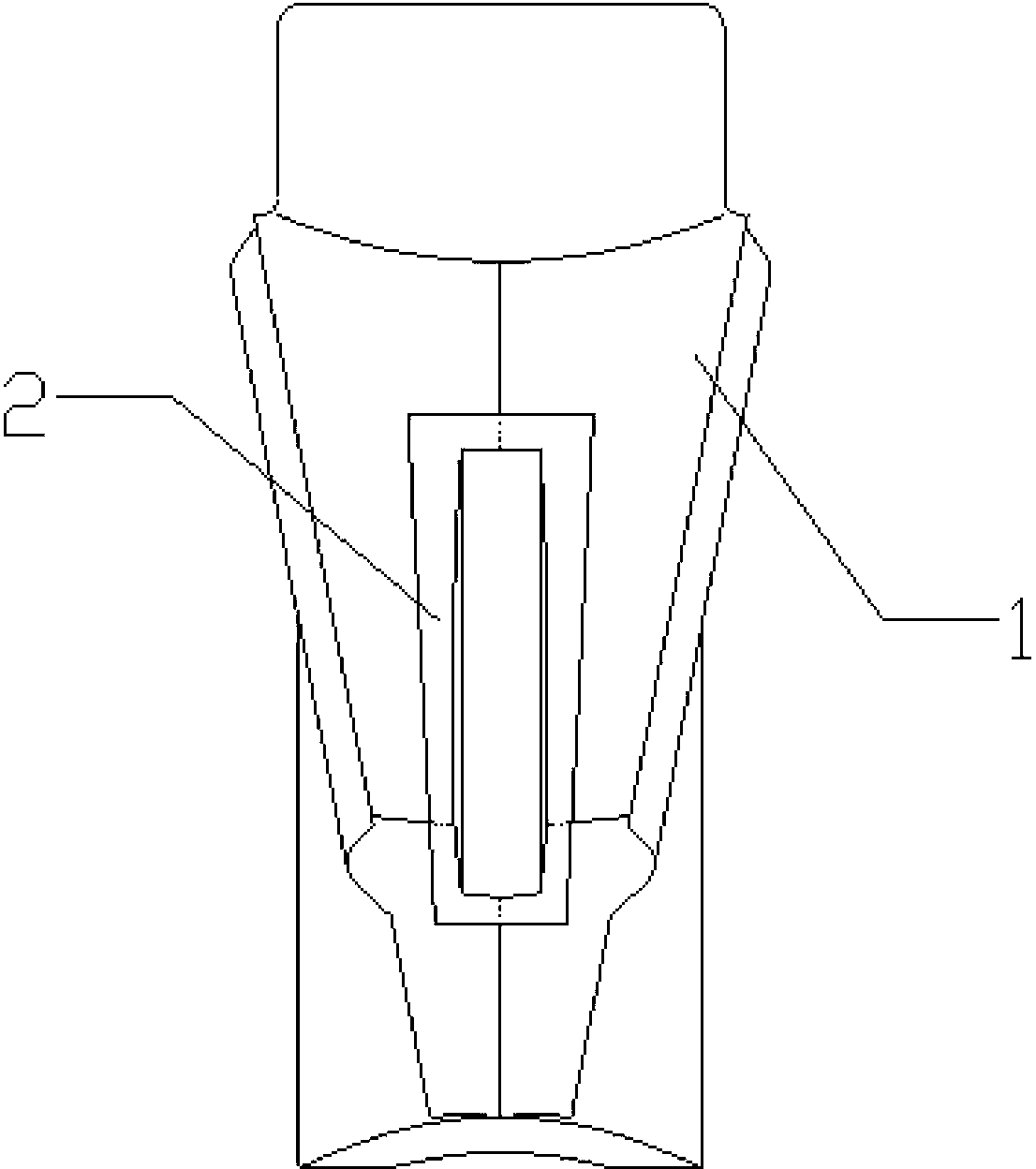

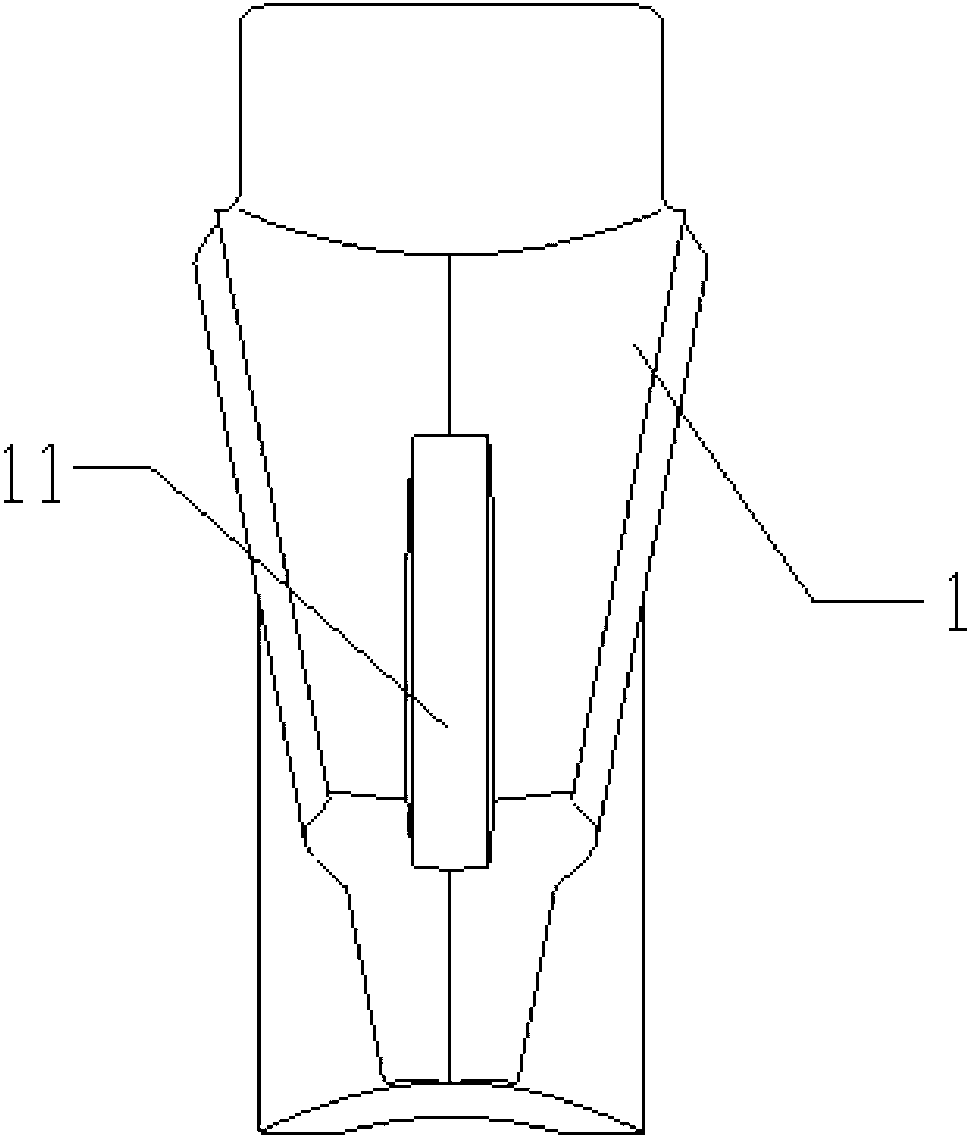

[0035] Such as figure 1 , a mosaic type spool, including a spool body 1, and a spool chute protection sleeve 2, the two sides of the spool body 1 are respectively provided with an inlay groove 11 for installing the spool chute protection sleeve 2.

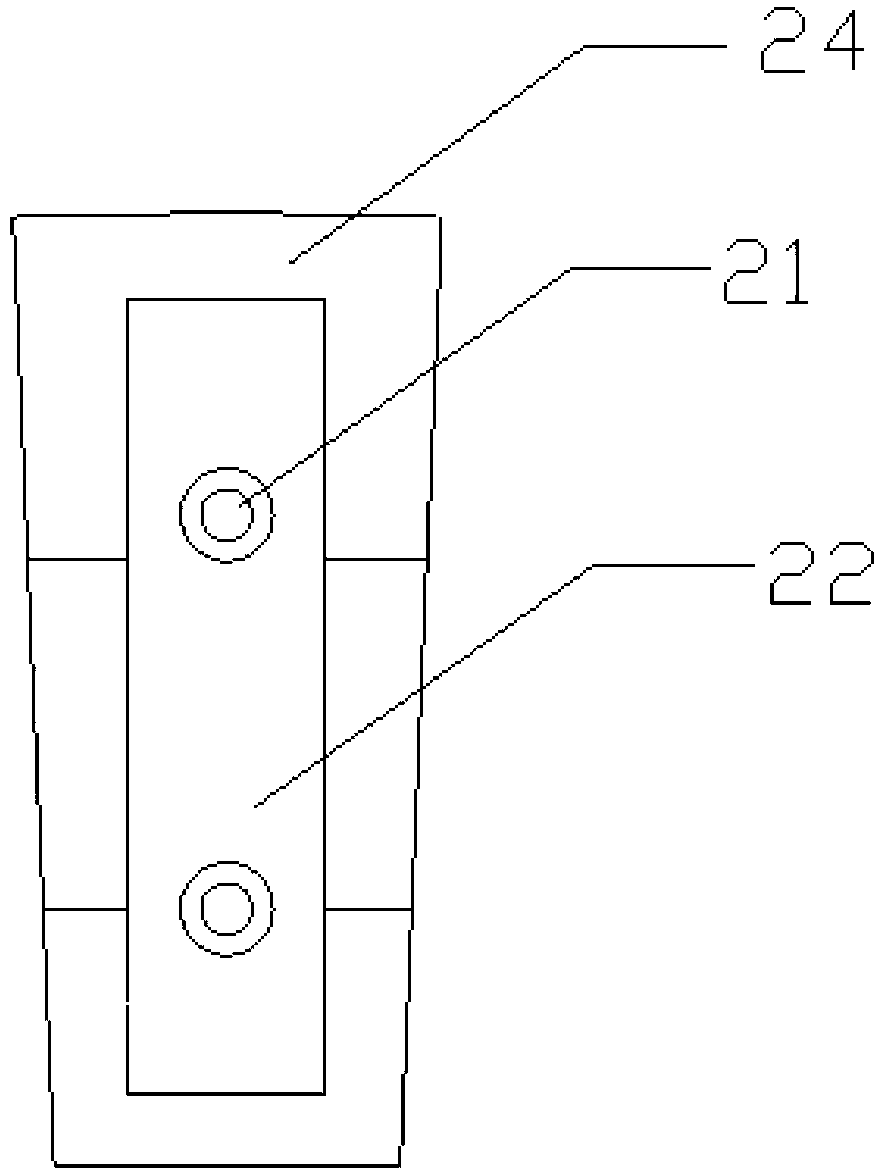

[0036] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the spool chute protective sleeve 2 includes an inlaid baffle 24, and a positioning groove 22 is arranged in the inlaid baffle 24, and a plurality of positioning holes 21 are arranged in the locating groove 22; the spool chute protective sleeve 2 is installed in the inlaid groove 11 After that, they are fixed to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com