Two-dimensional reproduction method for petroleum pipeline defects through least squares support vector machines (LS-SVM)

A technology of support vector machine and least squares, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of complex inverse problem and large amount of calculation, achieve online reconstruction and improve convergence accuracy , to solve the effect of slow training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

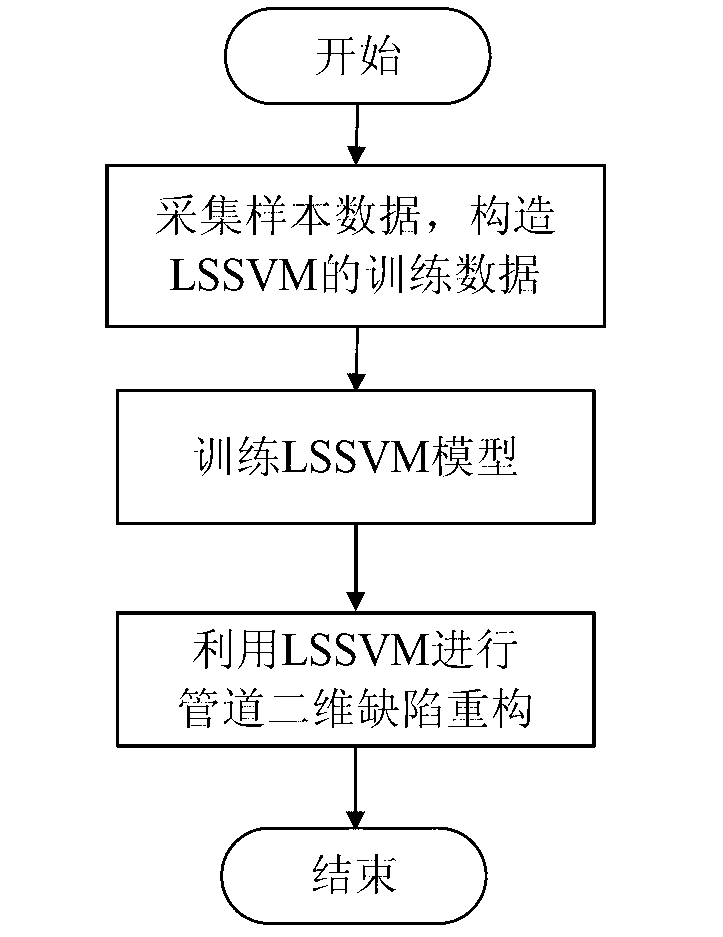

[0047] The process of predicting the geometric parameters of defects according to the magnetic flux leakage signals generated by defects is essentially a process of establishing the mapping relationship between magnetic flux leakage signals and geometric parameters of defects.

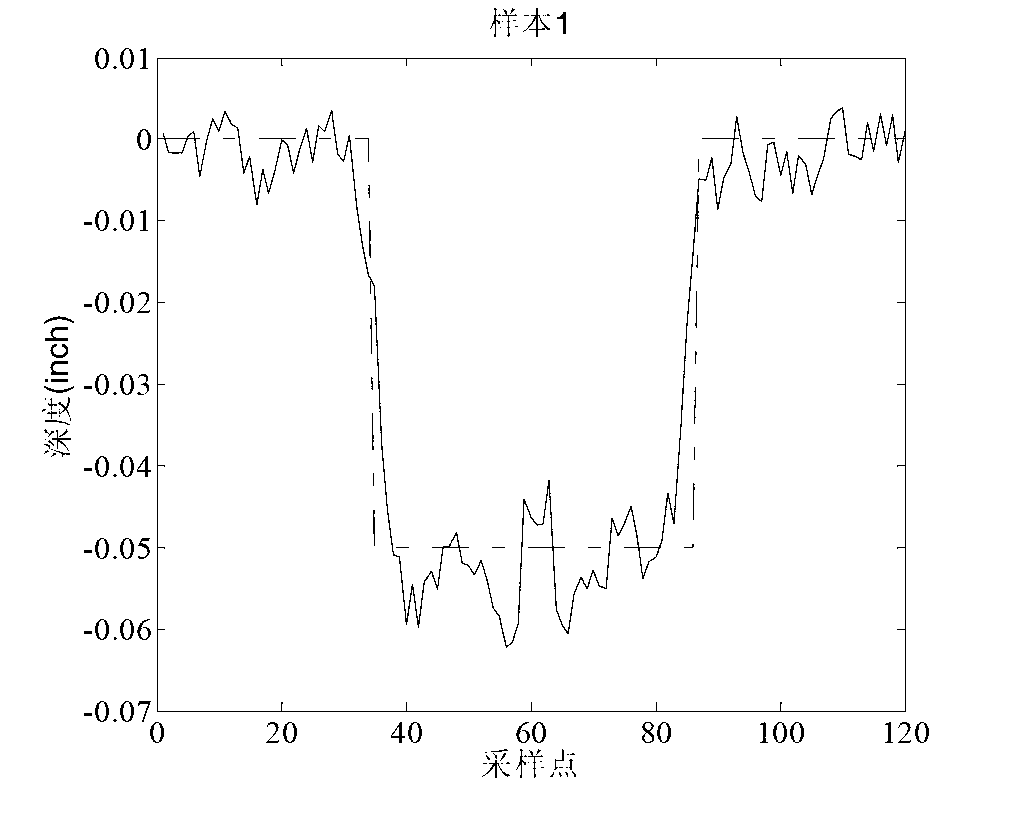

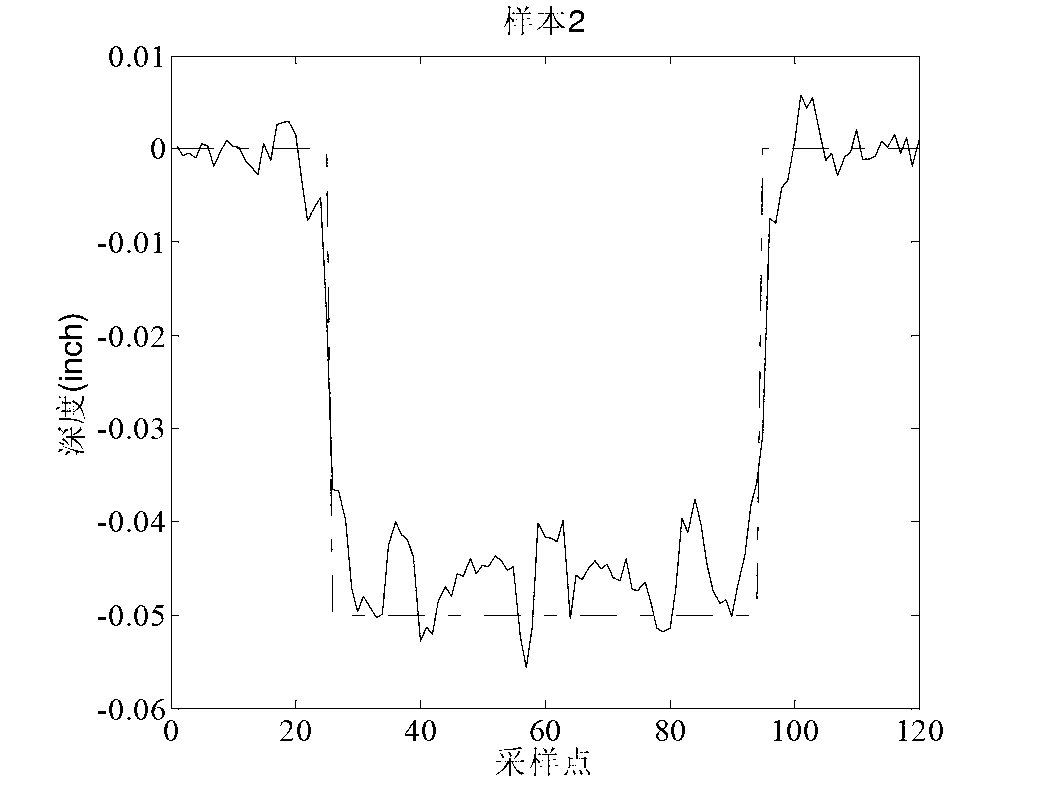

[0048] (1) The measured values of MFL signals and defects collected from actual pipelines are used as experimental data for network training after preprocessing such as denoising and normalization. There are 90 sets of sample data, the first 80 sets are used as training data, the last 10 sets are used as test data, and each set of data has 120 sampling points.

[0049] (2) Set the least squares support vector machine parameters: kernel function parameter σ and penalty factor γ. The magnetic flux leakage signal is used as the input of the least squares support vector machine, and the defect contour (length and depth) is used as the output.

[0050] Use the least squares support vector machine for two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com