A vehicle-mounted fuel cell vibration test system simulating actual driving conditions

A fuel cell and vibration testing technology, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problems of poor time-varying and nonlinear adaptation effect, economical, dynamic decline, complex structure, etc. , to achieve the effect of improving reliable reproduction, achieving accurate reproduction, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

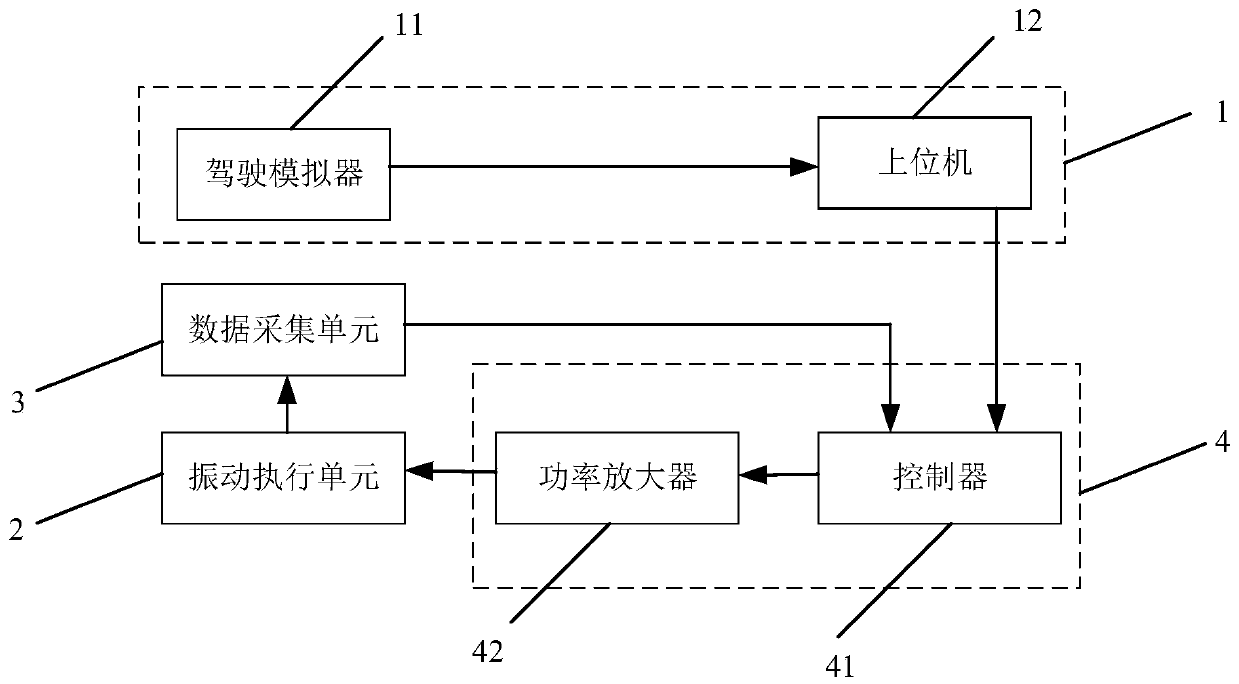

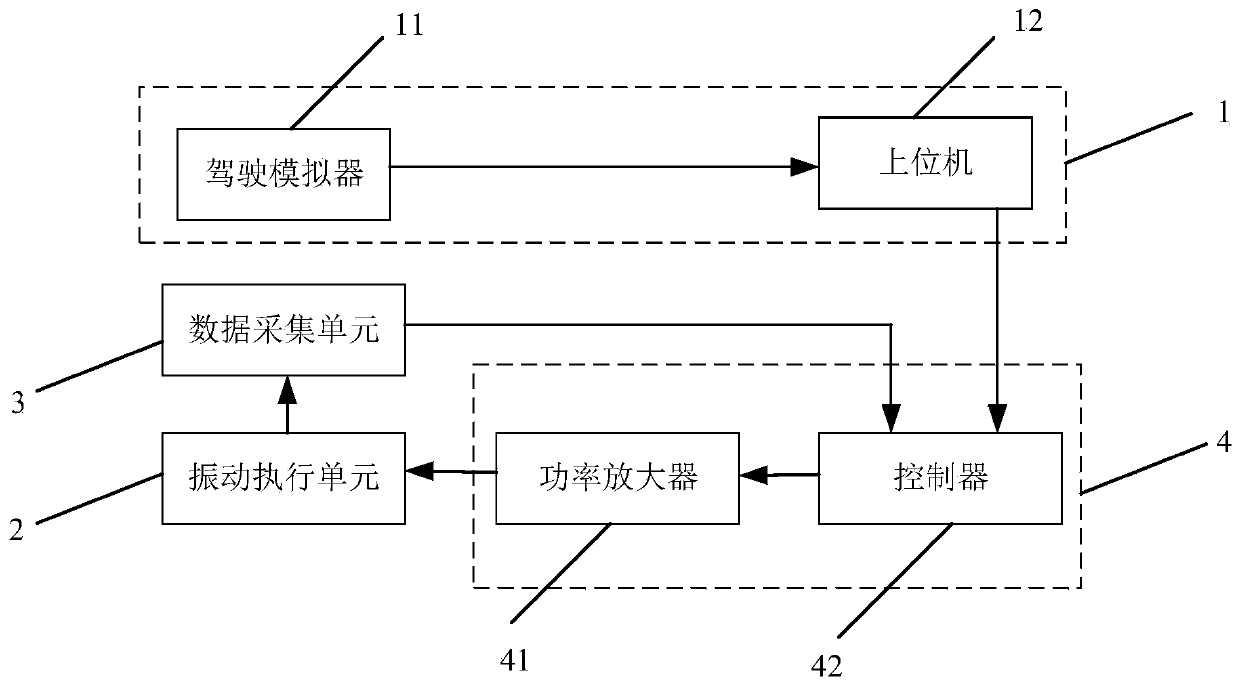

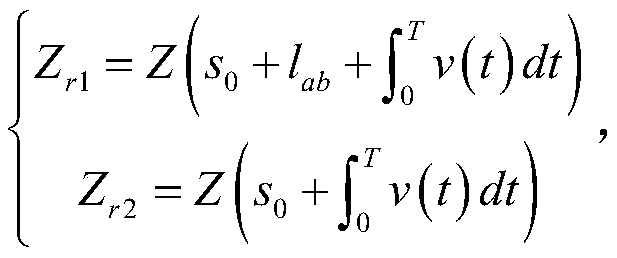

[0026] Such as figure 1 As shown, a vehicle-mounted fuel cell vibration test system that simulates actual driving conditions is used to simulate the reproduction of the vehicle-mounted fuel cell vibration state under actual driving conditions. The system includes a vertical vibration signal real-time generation unit 1, a vibration execution unit 2. The data acquisition unit 3 and the control unit 4, the vertical vibration signal real-time generation unit 1 simulates the vertical vibration target signal at the vehicle fuel cell under different vehicle speeds and road surface roughness, the vibration execution unit 2 generates vertical vibration, and the data Acquisition unit 3 collects the actual vertical vibration signal of vibration execution unit 2, and control unit 4 performs tracking control on vibration execution unit 2 according to the vertical vibration target signal and vertical vibration actual signal, and then vibration execution unit 2 performs vertical vibration tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com