A Design Method of Single Heat Exchange Fin for LNG Vaporizer

A technology of heat exchange fins and a design method, applied in the field of LNG vaporizers, can solve the problems of not producing high-efficiency heat exchange fins, large space required for installation, reduced use efficiency, etc., and achieves reduced installation space, large safety factor, The effect of large evaporation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

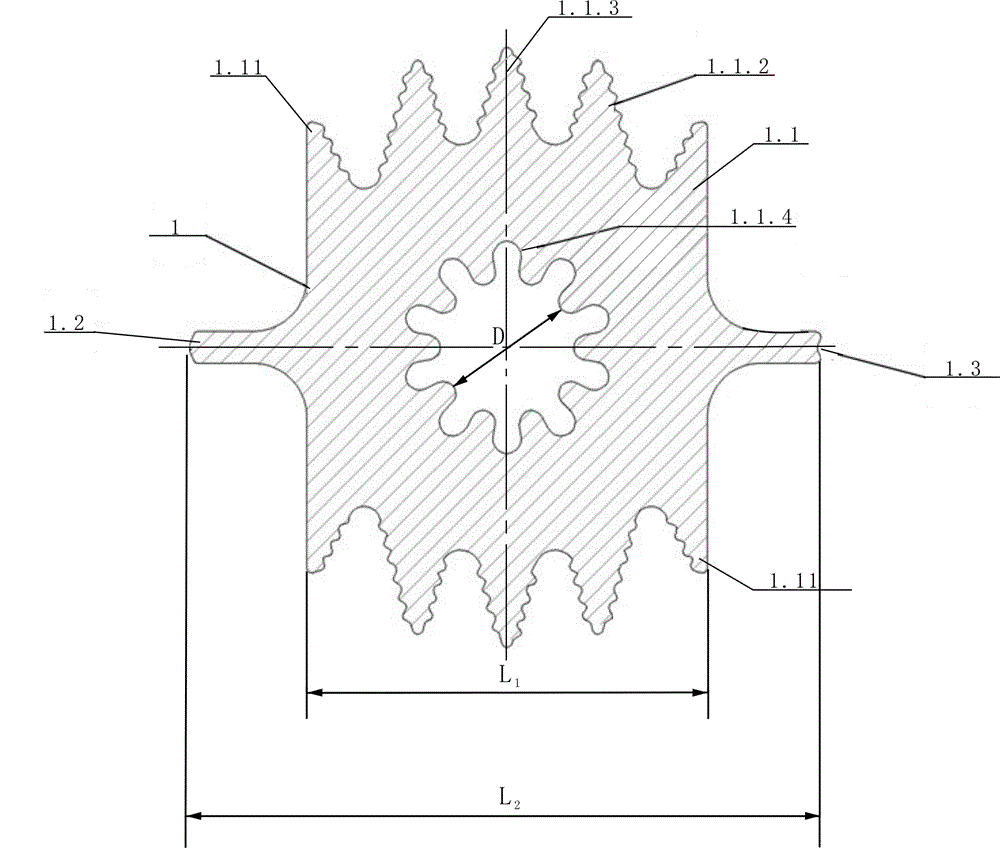

[0018] A single-piece heat transfer fin design method for LNG vaporizers. The single-piece heat transfer fins designed by this design method not only have a small installation space and a large evaporation capacity, but also have a high pressure bearing capacity and are safe. The coefficient is large, the heat exchange effect is good, and the freezing thickness and height of the LNG vaporizer are reduced.

[0019] First set the width of the LNG vaporizer to be installed and positioned as L 2 And the diameter of the heat exchange pipe is D, and the single heat exchange fin 1 includes a base 1.1, an inner hole arranged on the centerline of the base, a left bracket 1.2 and a right bracket 1.3 connected to the left and right ends of the base, and the diameter of the inner hole = D.

[0020] figure 1 It is a single heat exchange finned tube with five outer fins, the present invention is not limited to figure 1 As indicated, the purpose of disclosing the invention is to protect al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com