Diesel engine cylinder cover valve seat conical surface jumping special gauge

A cylinder head and diesel engine technology, applied in the field of machined parts inspection, can solve the problems of high cost, long inspection time of three-coordinate measuring instrument, unsuitable for batch product inspection, etc., achieve low manufacturing cost, reduce inspection cost, and meet inspection requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of detection of the beating deviation of the cone surface of the cylinder head valve seat of a marine diesel engine.

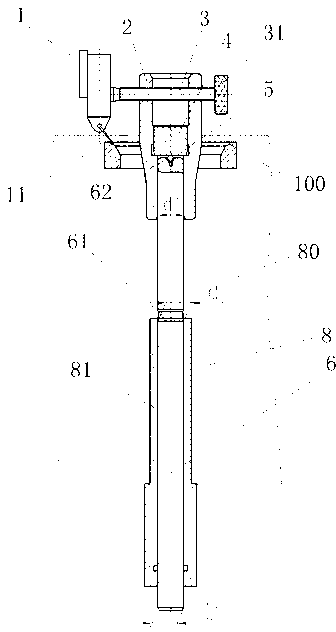

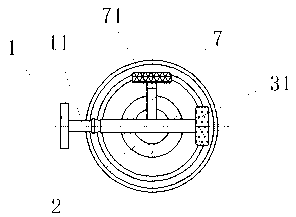

[0017] Such as figure 1 and figure 2 As shown, the present invention comprises a lever dial indicator 1, a dial sleeve 2, a threaded pin 3, a plug 4, a steel ball 5, a mandrel 6 and a locking pin 7, and the middle part of the mandrel 6 is provided with an undercut 61, and the core The diameter D of the lower end of the rod 6 is greater than the diameter d of the middle part of the mandrel 6 on the lower side of the undercut 61 , the diameter d1 of the upper part of the mandrel 6 on the upper side of the undercut 61 is smaller than the diameter d1 of the middle part of the mandrel 6 , and the diameter D of the lower end of the mandrel is the same as that of the middle part of the mandrel The difference in diameter d is 0.04-0.07mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat treatment hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com