An automatic detection device for the roundness of the inner ring of a bearing and its application method

An automatic detection device and bearing inner ring technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems affecting the performance and life of bearing products, high labor intensity of workers, and low degree of automation, so as to achieve convenient operation and maintenance , Fast and simple installation, fast replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

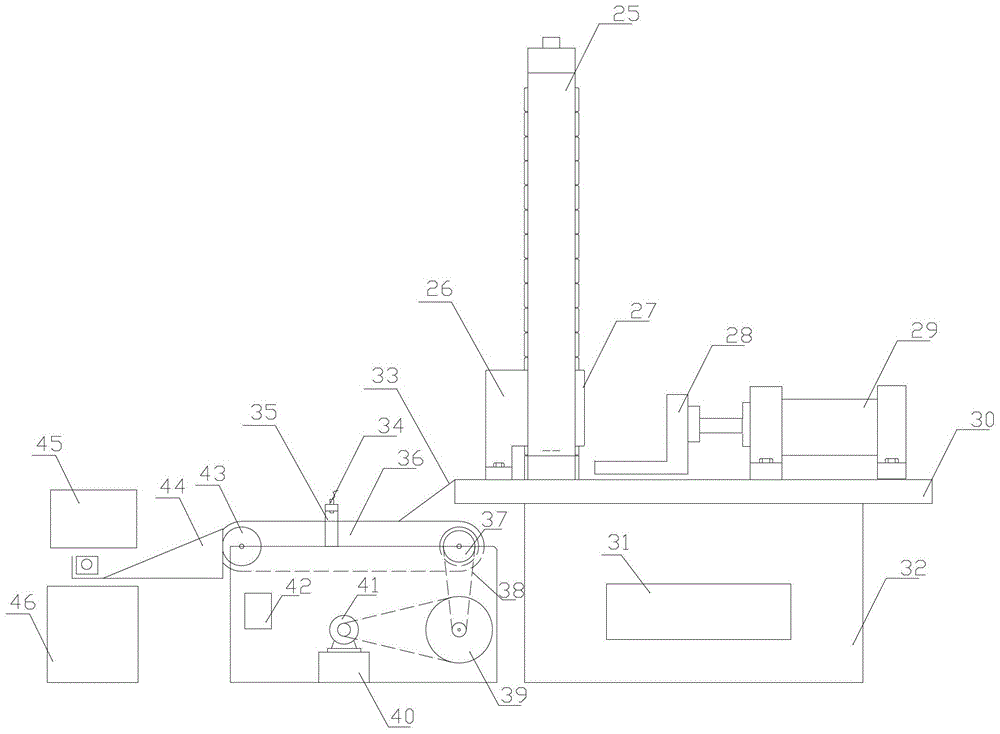

[0039] An automatic detection device for the roundness of the inner ring of a bearing, comprising a vertical operation cabinet, a material discharge mechanism, a workpiece installation mechanism, a horizontal conveying mechanism, a positioning mechanism, and a measuring mechanism.

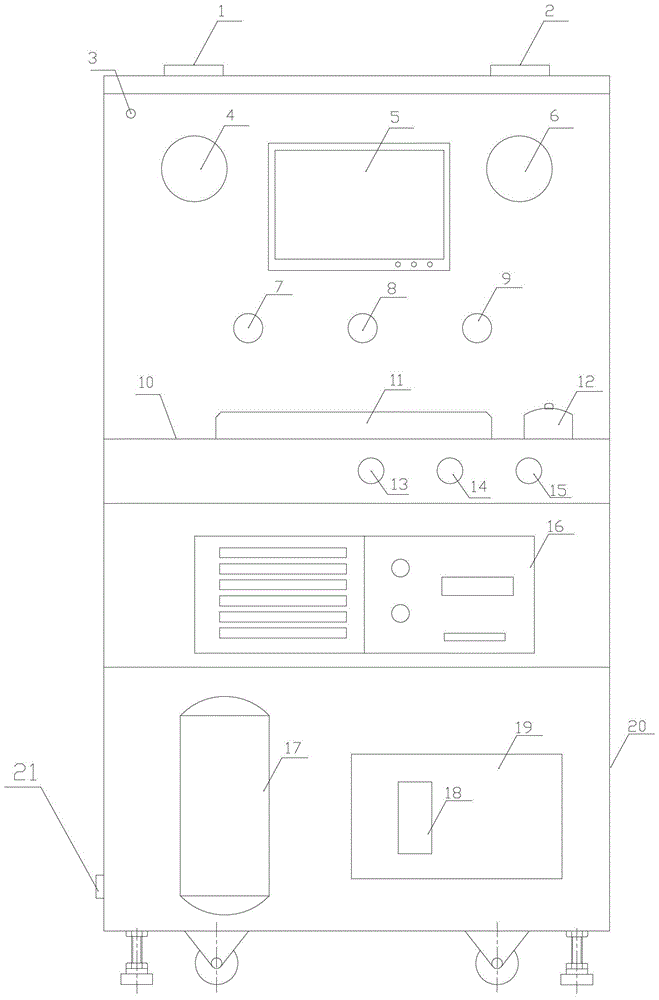

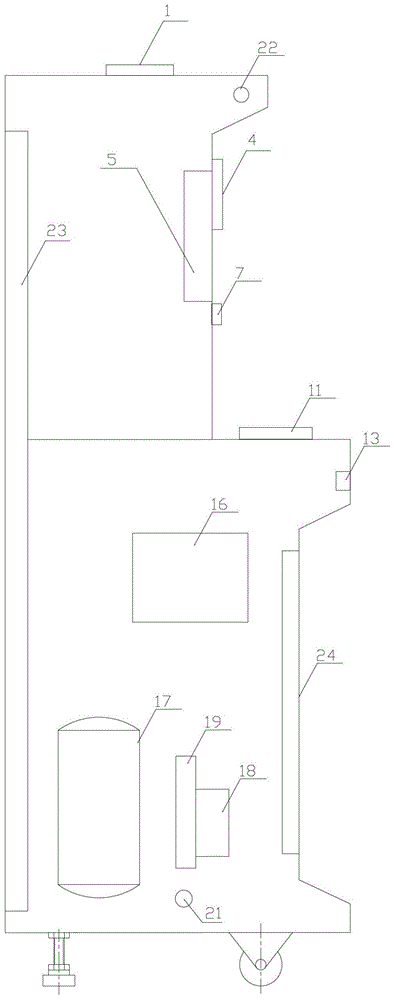

[0040] Such as figure 2 , image 3 As shown, the vertical operation cabinet includes a left exhaust fan 1, a right exhaust fan 2, an air source pressure gauge 4, a liquid crystal display 5, a fixture air pressure gauge 6, a fluorescent lamp 22, a 220V power supply indicator light 7, and a qualified indication Light 8, unqualified indicator light 9, operation cabinet workbench 10, keyboard 11, mouse 12, start key 13, stop key 14, reset key 15, industrial computer 16, gas storage tank 17, electrical drive board 19, Delta PLC Control module 18, vertical cabinet 20, power supply air source inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com