Dynamic brake performance testing device of integrated type electronic parking brake system

A technology of electronic parking brake and test device, which is applied in the direction of vehicle test, measurement device, machine/structural component test, etc., can solve the problems of high risk factor and high cost of vehicle test, and achieve simple structure and dynamic test bench. Optimized braking performance and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

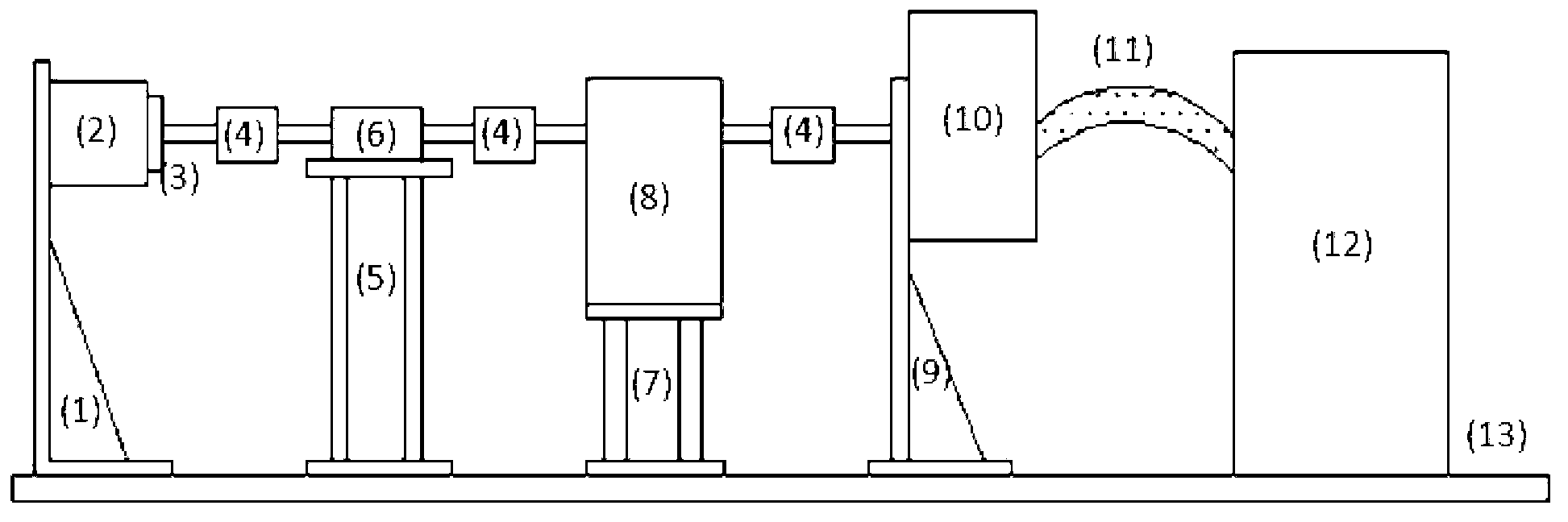

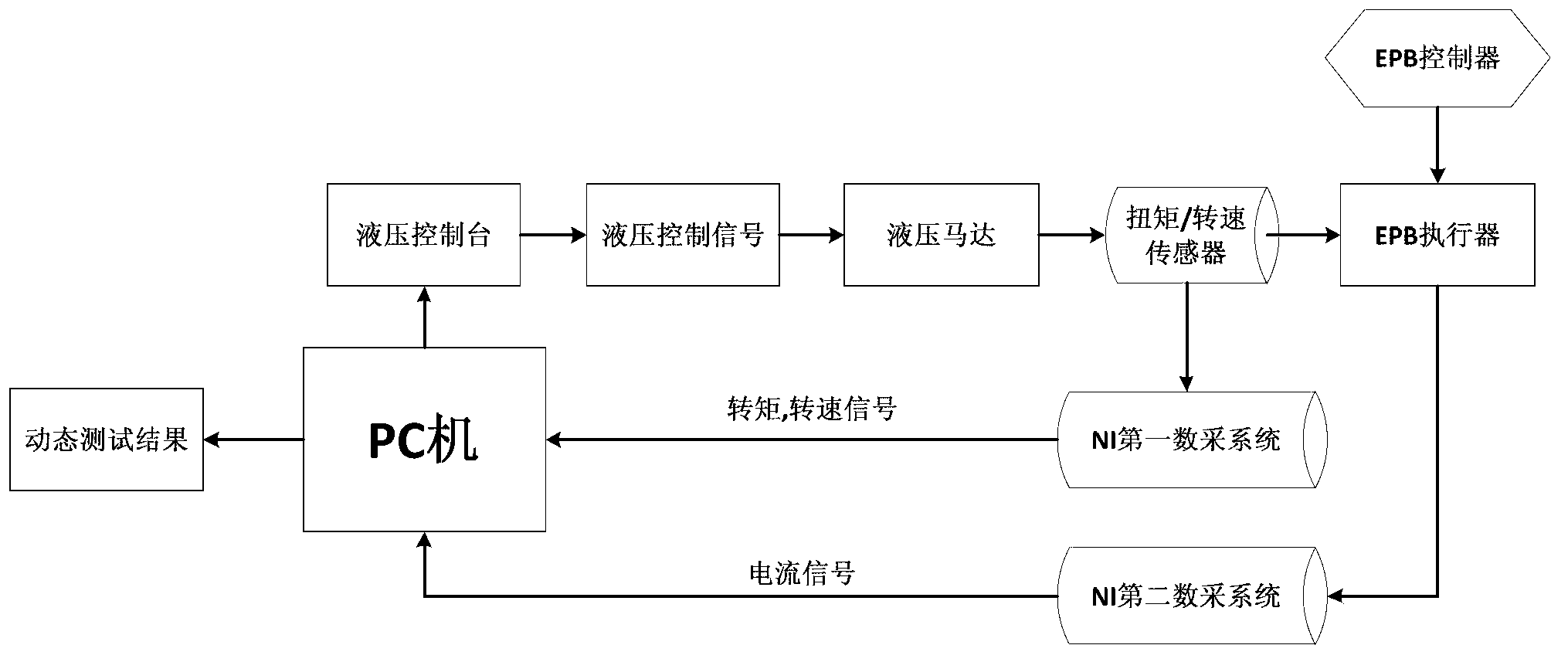

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention includes two parts of a mechanical transmission device and a control device. The mechanical device consists of a brake bracket 1, a brake 2 with EPB, a flange 3, a shaft coupling 4, a sensor support 5, and a torque speed sensor 6. , reducer support 7, reducer 8, hydraulic motor support 9, hydraulic motor 10, hydraulic pipeline 11, hydraulic control console 12, pedestal base 13 is made up; Described control device part is made up of hydraulic control console 12, torque speed sensor 6 , PC, and EPB controller.

[0015] The brake 2 with EPB is fixed on the brake bracket 1, and the brake bracket 1 is fixed on the base 13 of the stand through the feet, and the flange 3 is connected to the brake disc in the brake 2 with EPB, and through the coupling 4 is connected to the torque speed sensor 6, and the torque speed sensor 6 is fixed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com