An enhanced boiling heat transfer test device and test method

A test device and enhanced boiling technology, applied in the field of boiling heat transfer, can solve the problems of difficult verification accuracy, smooth surface can not meet the requirements, complex data processing, etc., to achieve accurate test stability, good container sealing effect, test The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

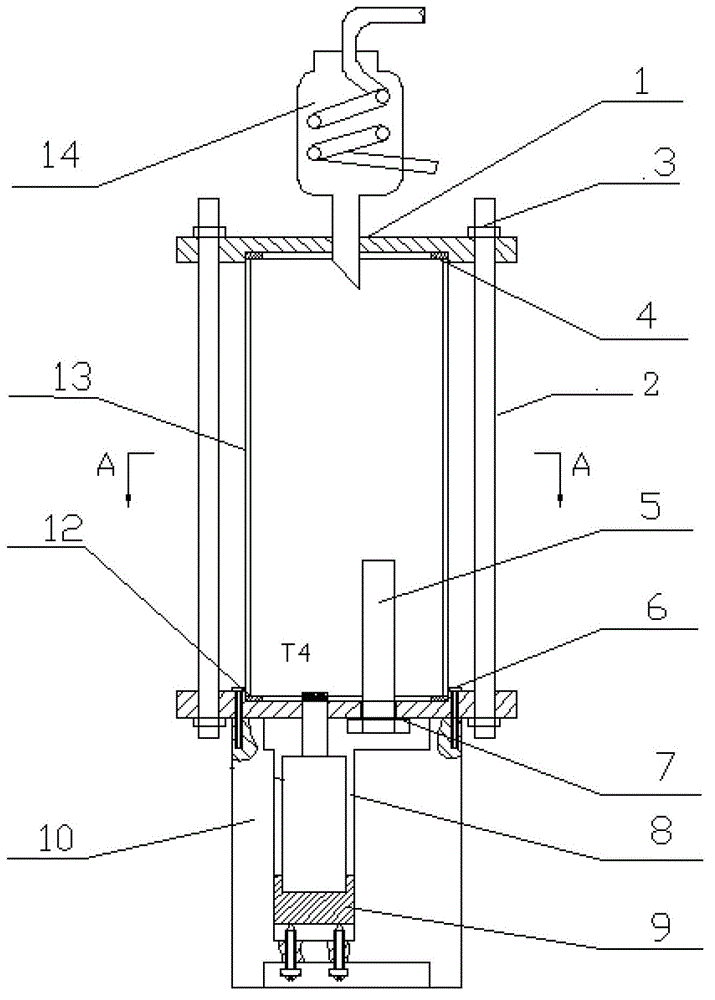

[0041] like figure 1 Shown is an enhanced boiling heat transfer test device, comprising a condenser 14, a main container, a base 10 and a heater;

[0042] The condenser 14 communicates with the main container, specifically connected to the through hole between the left and right ends of the upper cover plate 1, and is used to collect the working fluid when the main container boils, and the gas condenses and flows back to the main container, while the opening is connected to the outside world. Keep the air pressure of the main container stable during the test, and always maintain an atmospheric pressure.

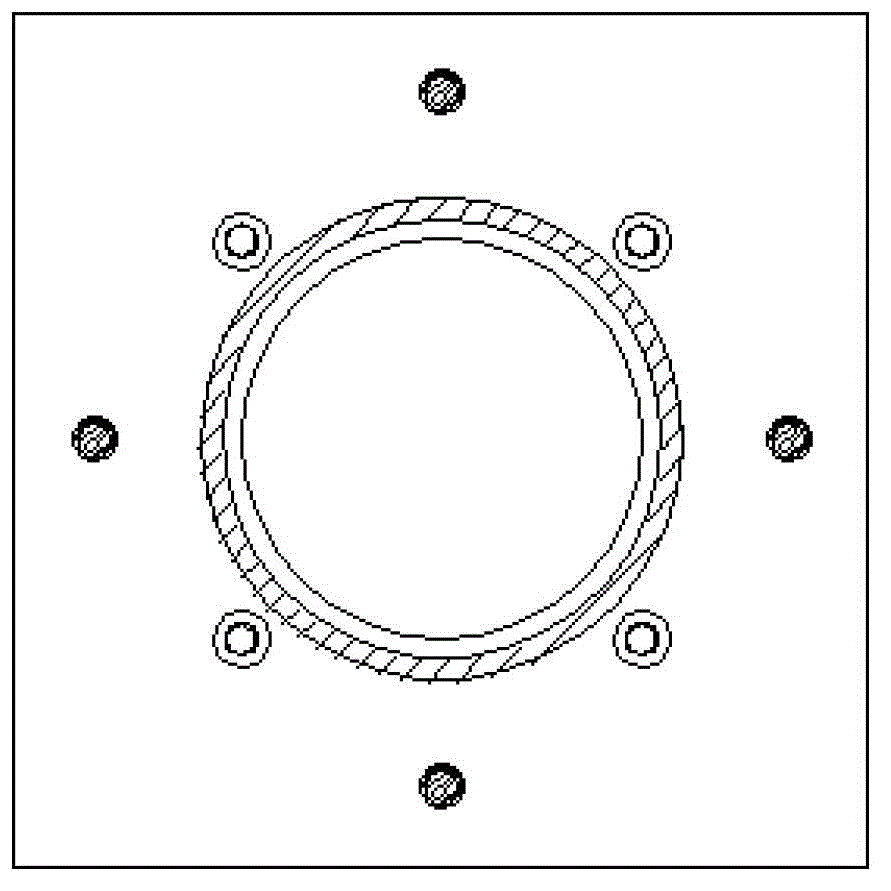

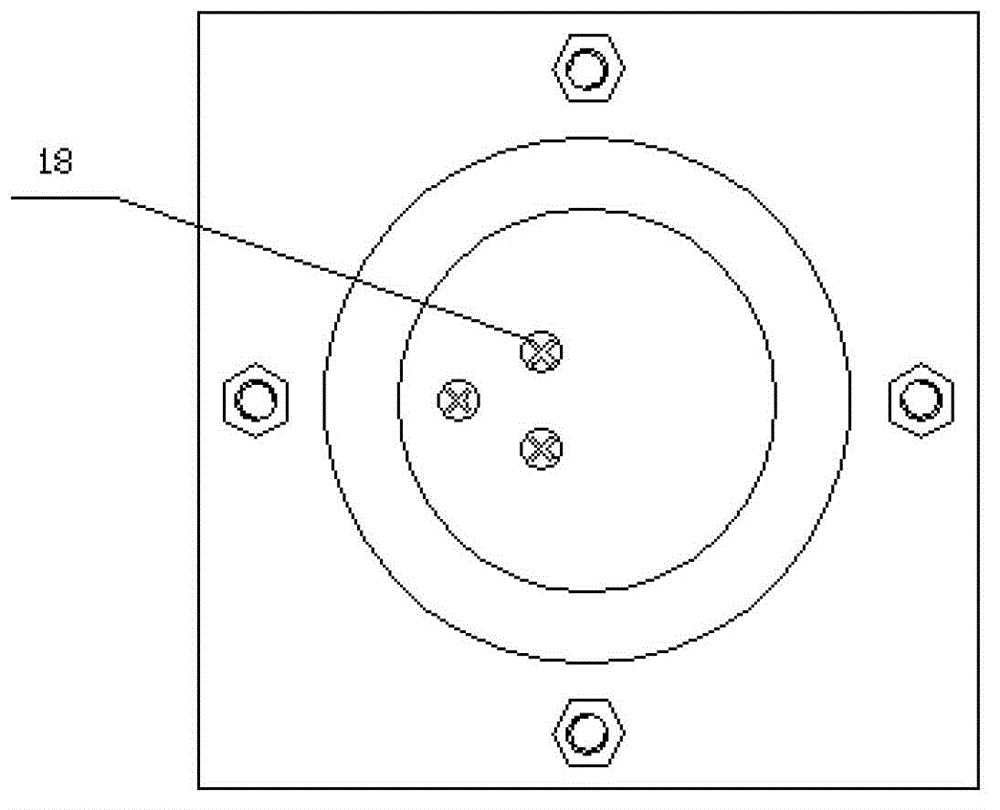

[0043] The main container comprises a glass container 13, a screw mandrel 2, an upper cover plate 1 covered at the top of the glass container and a lower cover plate 12 covered at the bottom end of the glass container, the glass container 13 is transparent, and the upper and lower cover plates The left and right ends of each have through holes for connecting the screw mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com