Double-clad optical fiber

A double-clad optical fiber and cladding technology, which is applied in the direction of cladding optical fiber, multi-layer core/cladding optical fiber, etc., can solve the problems of complex stacking process, etc., and achieve simple production operation, reduced coating cost, and easy process realization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

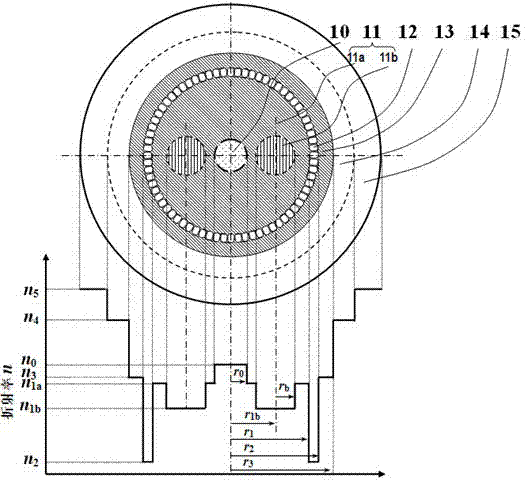

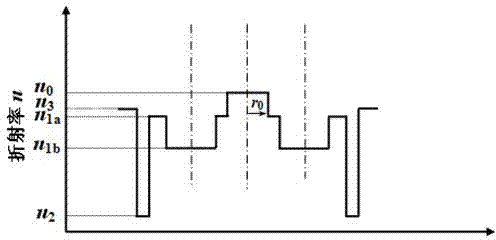

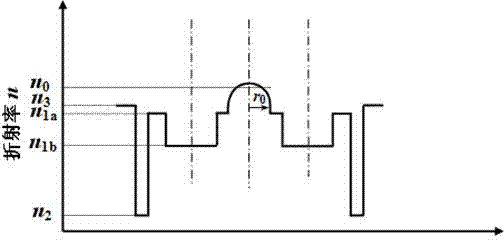

[0031] Example 1 , according to the optical fiber structure design requirements listed in Table 1, the chemical vapor deposition process was used to prepare Er-doped 3+ and Al 3+ The silica-based glass core rod of the company uses a quartz tube to outsource the doped core rod, and then bores through holes in the cladding with the doped silica glass core as the symmetry.

[0032] On the other hand, two boron-doped stress rods are prepared by chemical vapor deposition, and the stress rods are processed to match the size of the bore hole. Clean the surface of the bore and stress rods and assemble them together.

[0033] Then, on the periphery of the combination rod, the capillary is stacked and jacketed with a large-pore quartz tube. After the rod-tube assembly is fixed, it is cleaned. Then put it into the drawing tower, and draw it at 1700-2100 °C. At the same time, the conventional optical fiber coating is applied and cured to protect the optical fiber.

[0034] figure ...

Embodiment 2

[0035] Example 2 , according to the optical fiber structure design requirements listed in Table 1, the porous SiO 2 layer, and then use the solution soaking doping method to prepare Tm-doped 3+ and Al 3+ The silica-based glass core rod of the company uses a quartz tube to outsource the doped core rod, and then bores through holes in the cladding with the doped silica glass core as the symmetry.

[0036] On the other hand, two boron-doped stress rods are prepared by chemical vapor deposition process, and the stress rods are processed to match the size of the above-mentioned bore hole. Clean the surface of the bore and stress rods and assemble them together.

[0037] Then, on the periphery of the combination rod, the capillary is stacked and jacketed with a large-pore quartz tube. After the rod-tube assembly is fixed, it is cleaned. Then put it into the drawing tower, and draw it at 1700-2100 °C. At the same time, the conventional optical fiber coating is applied and cure...

Embodiment 3

[0039] Example 3 , according to the optical fiber structure design requirements listed in Table 1, first use chemical vapor deposition process to prepare Ge or P doped porous SiO 2 layer, and then use the solution soaking doping method to prepare only doped Yb 3+ or Yb 3+ 、Al 3+ For the co-doped silica-based glass core rod, the doped core rod is covered by a quartz tube, and then in the cladding, the doped silica glass core is symmetrical, and through holes are respectively bored.

[0040] On the other hand, two boron-doped stress rods are prepared by chemical vapor deposition process, and the stress rods are processed to match the size of the above-mentioned bore hole. Clean the surface of the bore and stress rods and assemble them together.

[0041] Then, on the periphery of the combination rod, the capillary is stacked and jacketed with a large-pore quartz tube. After the rod-tube assembly is fixed, it is cleaned. Then put it into the drawing tower, and draw it at 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com