Polyvinyl alcohol-based film, polarizing film and polarizing plate, and method for producing polyvinyl alcohol-based film

A technology of polyvinyl alcohol-based and manufacturing methods, applied to polarizing elements, optical elements, flat products, etc., can solve the problems of polyvinyl alcohol-based film rupture productivity, etc., achieve excellent swelling and stretchability, and appropriate birefringence , The effect of less chromaticity unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0179] (Production of polyvinyl alcohol-based film)

[0180] In a 5000L dissolving tank, add 1000kg of polyvinyl alcohol-based resin with a weight average molecular weight of 142000 and a saponification degree of 99.8 mol%, 2500kg of water, 105kg of glycerin as a plasticizer, and 0.25kg of polyoxyethylene laurylamine as a surfactant, It heated up to 150 degreeC, carried out pressure-dissolution with stirring, and adjusted the concentration to obtain the aqueous solution of the polyvinyl-alcohol-type resin with a resin density|concentration of 25 weight%. Then, after supplying the polyvinyl alcohol-based resin aqueous solution to a twin-screw extruder for defoaming, the temperature of the aqueous solution was set at 95° C., and it was discharged from a discharge port of a T-shaped slot die (discharge speed 1.3 m / min) and cast onto the surface. Film formation was performed on a casting drum at a temperature of 80°C. The formed film was peeled from the casting drum, and was drie...

Embodiment 2

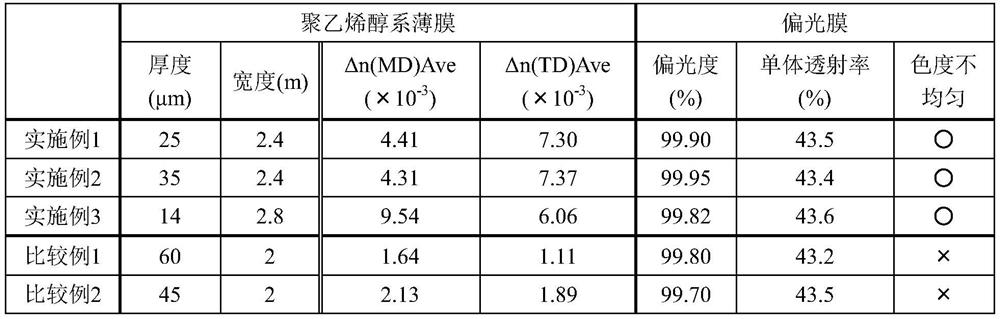

[0185] In Example 1, the polyvinyl alcohol-based resin aqueous solution was discharged (discharge speed 1.9m / min) and cast to a casting drum with a surface temperature of 88°C to form a film, and the same procedure as in Example 1 was performed. , and a film (width 2 m, thickness 45 μm) having a water content of 10% by weight was obtained. Then, in the same manner as in Example 1, the film was stretched 1.2 times in the width direction (TD) at 80°C using a stretcher, and then transported in a dryer at 135°C with a fixed width of 2.4m to obtain a polyvinyl alcohol-based film. Film (width 2.4 m, thickness 35 μm, length 2 km). The properties of the obtained polyvinyl alcohol-based film are shown in Table 1 below.

[0186] Moreover, using the said polyvinyl-alcohol-type film, it carried out similarly to Example 1, and obtained the polarizing film and the polarizing plate. In the swelling step during the production of the polarizing film, the above-mentioned polyvinyl alcohol-bas...

Embodiment 3

[0188] In Example 1, except that the discharge speed at the time of film formation was set to 0.8 m / min, and film formation was carried out by discharge and casting, it was carried out in the same manner as in Example 1, and a moisture content of 5% by weight was obtained. film (width 2m, thickness 20μm). Then, in the same manner as in Example 1, the film was stretched 1.4 times in the width direction (TD) at 80°C using a stretcher, and then transported in a dryer at 130°C with a fixed width of 2.8m to obtain a polyvinyl alcohol-based film. Film (width 2.8 m, thickness 14 μm, length 2 km). The properties of the obtained polyvinyl alcohol-based film are shown in Table 1 below.

[0189] Moreover, using the said polyvinyl-alcohol-type film, it carried out similarly to Example 1, and obtained the polarizing film and the polarizing plate. In the swelling step during the production of the polarizing film, the above-mentioned polyvinyl alcohol-based film did not generate creases or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com