Intelligent air-cooling frequency-changing energy-saving system and method of transformer

A transformer, intelligent technology, applied in the direction of transformer/inductor cooling, program control in sequence/logic controller, electrical program control, etc., can solve the problems of poor cooling effect, poor flexibility, and uneconomical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

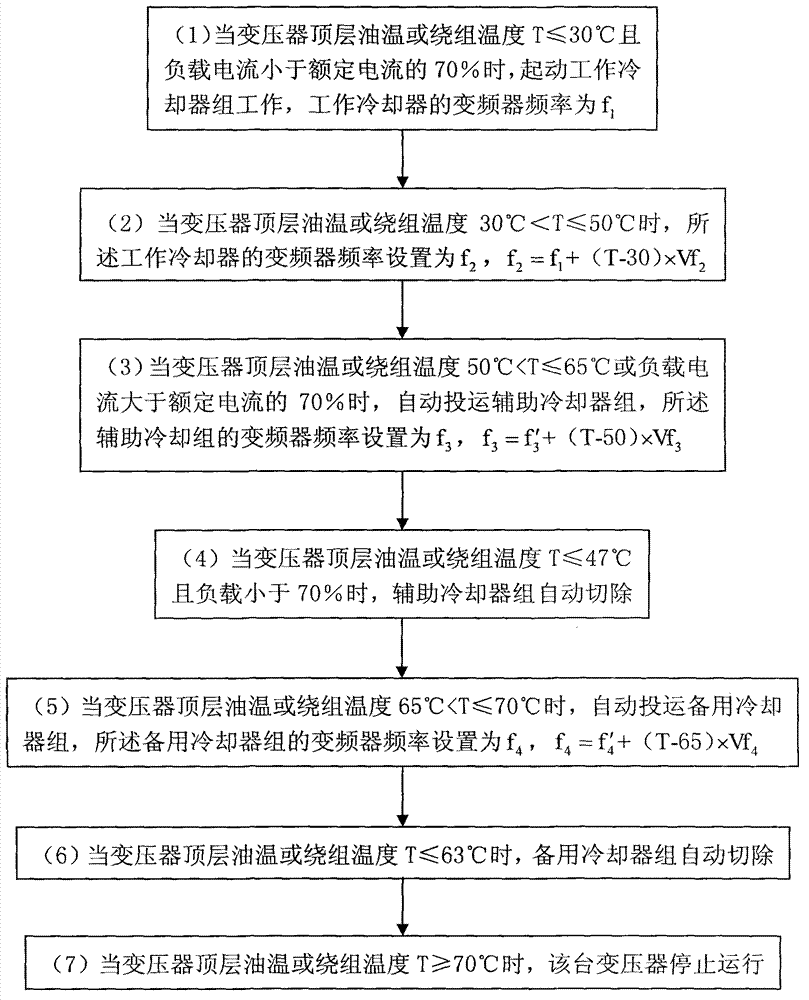

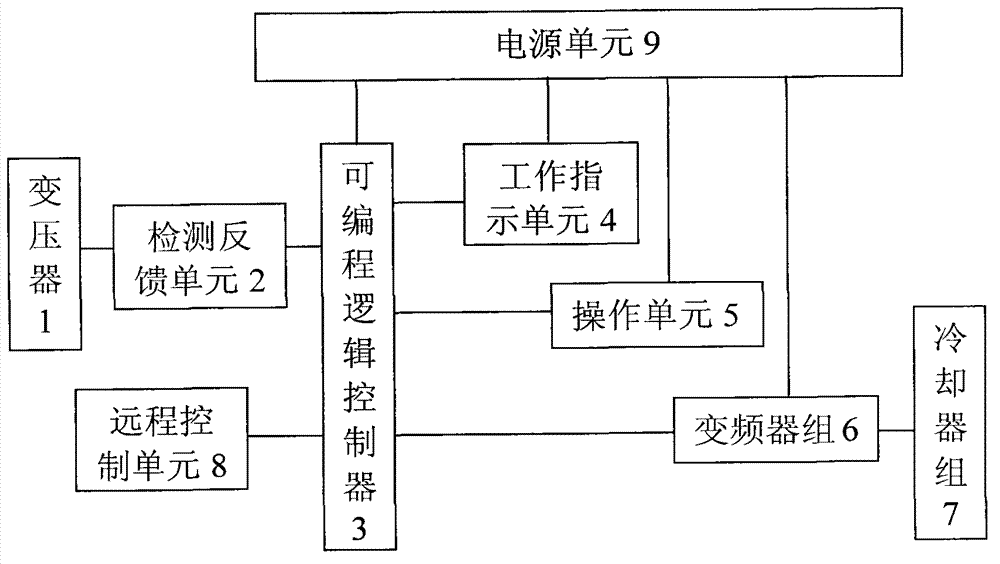

[0052] Flow chart of an energy-saving method for intelligent variable-frequency air-cooling of compressors provided in this embodiment figure 1 As shown, the transformer intelligent frequency conversion air-cooled energy-saving method is to jointly control the number of coolers and the fan speed according to the top oil temperature of the transformer, the winding temperature and the load current. The method is as follows:

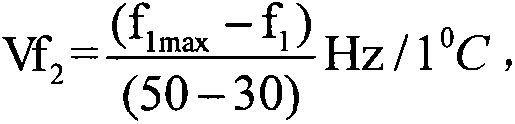

[0053] (1) When the oil temperature on the top layer of the transformer or the winding temperature T≤30°C and the load current is less than 70% of the rated current, start the working cooler group, and the maximum frequency of the frequency converter of the working cooler group is limited to f 1max , the initial frequency of the frequency converter of the working cooler group is f 1 , at this time the frequency converter of the working cooler group runs at the initial frequency f 1 , constant frequency and constant speed operation.

[0054] The initial fr...

Embodiment 2

[0094] Flow chart of an energy-saving method for intelligent variable-frequency air-cooling of compressors provided in this embodiment figure 1 As shown, the transformer intelligent frequency conversion air-cooled energy-saving method is to jointly control the number of coolers and the fan speed according to the top oil temperature of the transformer, the winding temperature and the load current. The method is as follows:

[0095] (1) When the oil temperature on the top layer of the transformer or the winding temperature T≤30°C and the load current is less than 70% of the rated current, start the working cooler group, the maximum frequency of the frequency converter of the working cooler group is limited to 48Hz, and the working The inverter frequency of the cooler group is 5Hz, running at constant frequency and constant speed.

[0096] (2) When the oil temperature on the top layer of the transformer or the winding temperature is 30℃

[0097] At this time, when the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com