Semiconductor laser temperature control system based on TEC

A temperature control system, laser technology, applied in temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of no TEC heat dissipation, complex design circuit, expensive chip, etc., to achieve less heat dissipation and low power consumption , The effect of improving power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but this should not be used as a limitation to the protection scope of the claims of the present application.

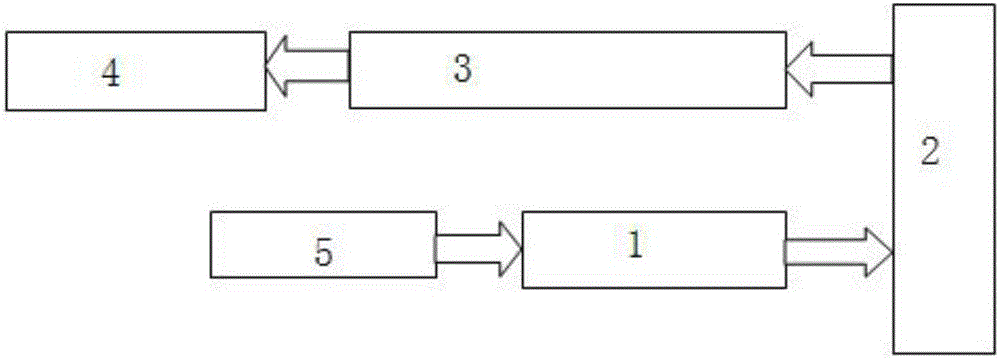

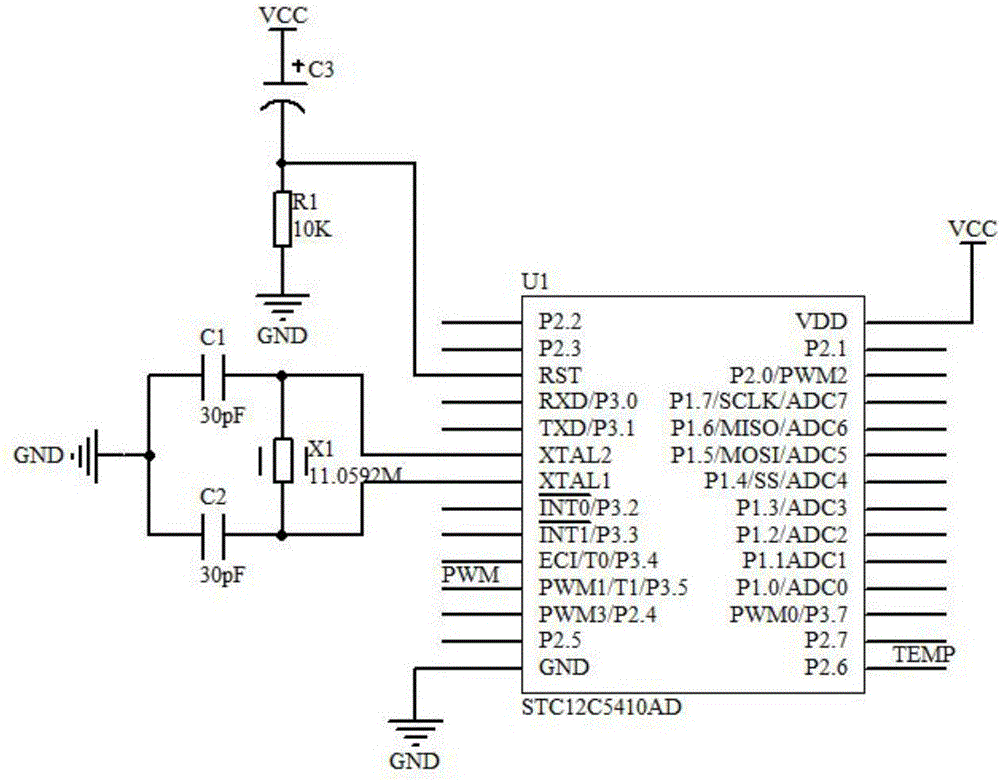

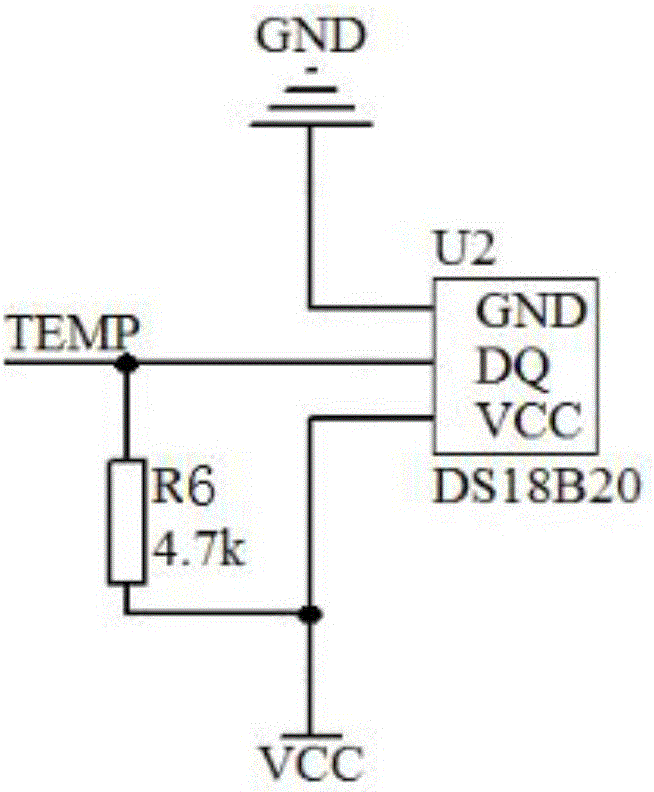

[0022] The present invention is based on TEC semiconductor laser temperature control system (abbreviation temperature control system, see Figure 1-6 ) includes a temperature sensor 1, a single-chip microcomputer 2, a TEC digital PWM power drive circuit 3 and a TEC cooling assembly 4, and the TEC cooling assembly 4 (see Figure 5 ) including TEC44, refrigeration block 41, heat dissipation aluminum plate 42 and exhaust fan 43, the cold surface and hot surface of TEC44 are evenly coated with thermal conductive silicone grease, the cold surface of TEC44 is close to refrigeration block 41, and the hot surface of TEC44 is close to heat dissipation aluminum plate 42, There is an exhaust fan 43 directly under the heat dissipation aluminum plate 42, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com