Non-end plate fuel cell stack fit for low-temperature starting

A fuel cell stack without end plate technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problem of water and heat balance of terminal electrodes, and achieve good water and heat balance, strong resistance to vibration, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

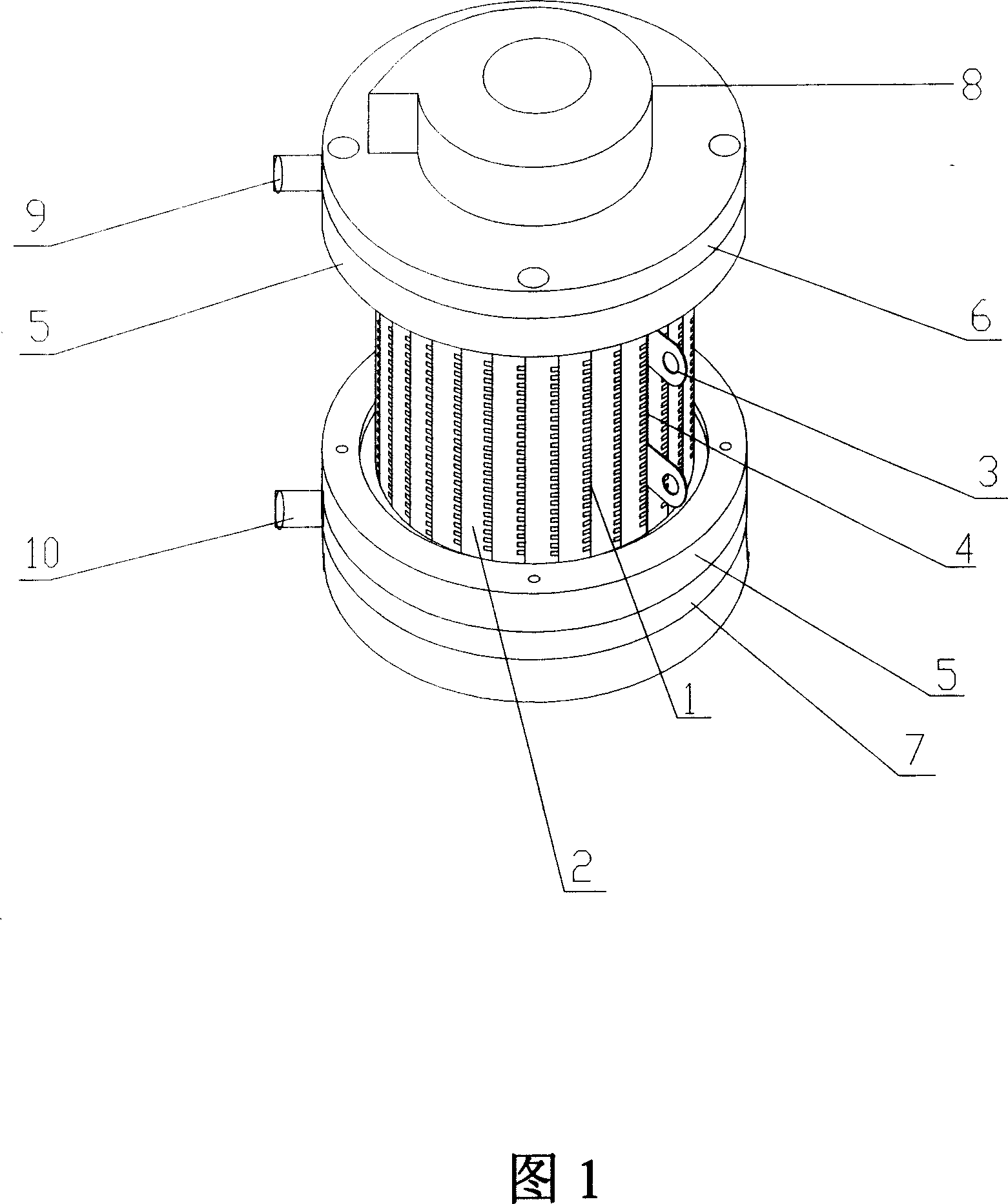

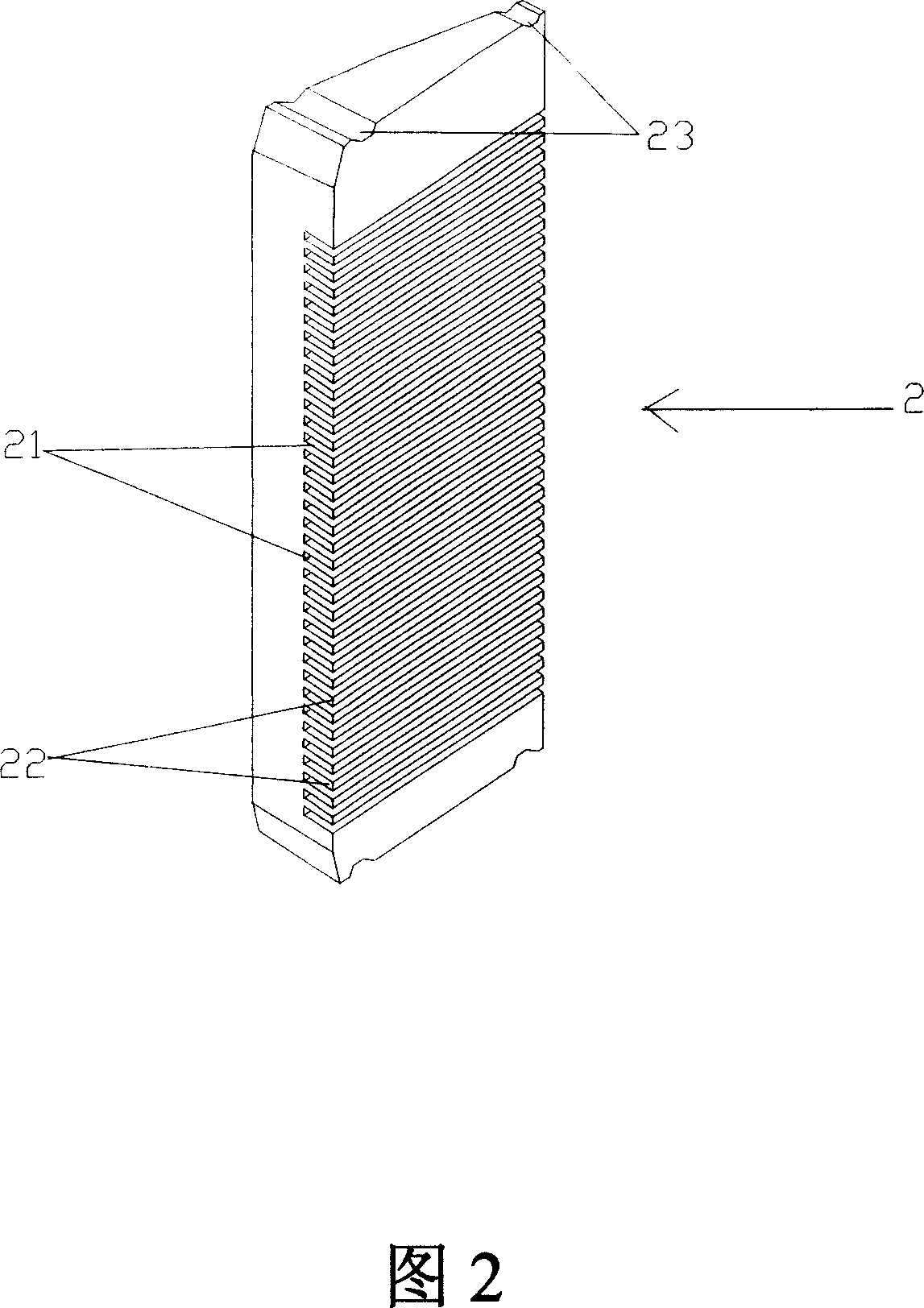

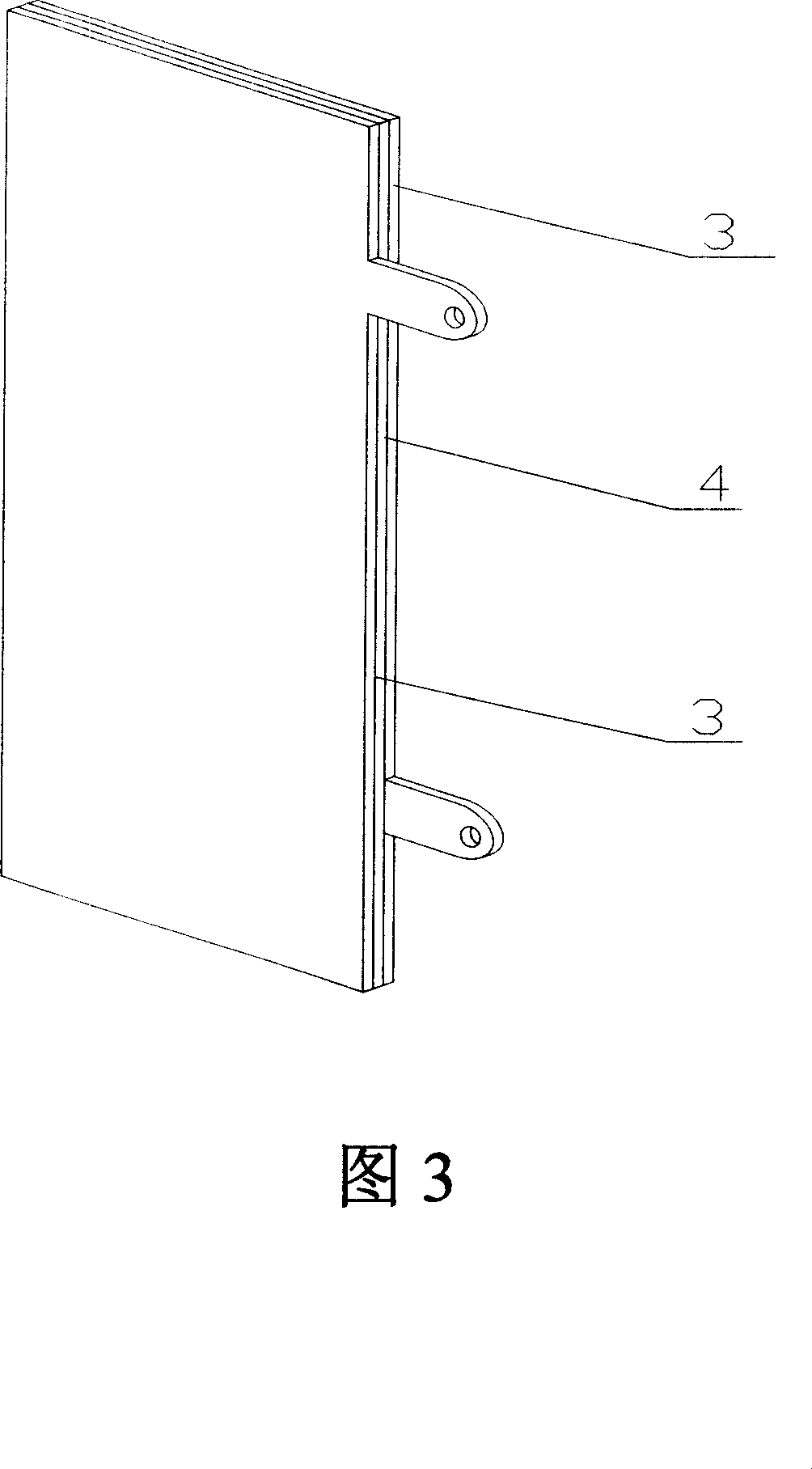

[0043] Referring to FIG. 1 , an end-plate fuel cell stack suitable for low temperature startup of the present invention includes a plurality of membrane electrodes 1 , a plurality of wedge-shaped bipolar plates 2 , at least one pair of current collector lead plates 3 , at least one electrically insulating separator 4 , Two fastening circles 5 , upper cover 6 , lower cover 7 and centrifugal fan 8 . Among them, an electrical insulating separator 4 is sandwiched between a pair of current collecting lead plates 3 to form a set of current output mechanisms. A plurality of membrane electrodes 1 , a plurality of wedge-shaped bipolar plates 2 and at least one group of current output mechanisms enclose a cylindrical fuel cell stack, and are fastened together by two fastening circles 5 . The upper end cover plate 6 and the lower end cover plate 7 are respectively connected to the upper and lower shaft ends of the cylindrical fuel cell stack, and the electrical insulating separator 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com