Touch control writing brush head with conductive function and manufacture method thereof

A brush and touch technology, applied in the electronic field, can solve the problems of damage to the capacitive touch screen, hard scratches of the capacitive touch screen, etc., and achieve the effect of soft texture and smooth touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

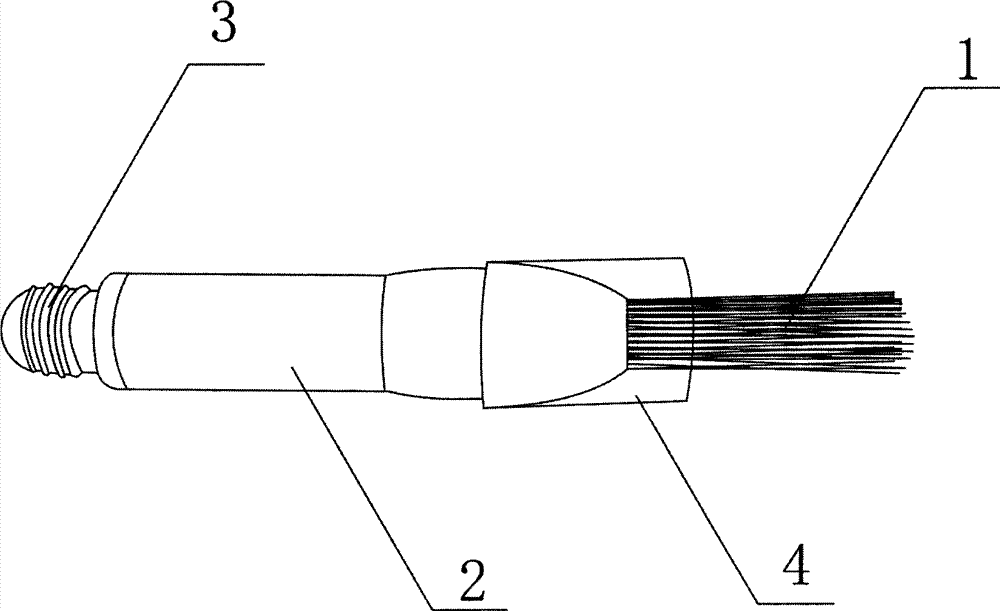

[0026] see figure 1 , a kind of touch writing brush tip with conductive function of the present invention, comprises conductive fiber filament bundle 1, metal casing 2 and bolt 3, and one end of conductive fiber filament bundle 1 is fixed on one end of metal casing 2, and metal casing The other end of the pipe 2 is fixedly connected with the bolt 3 . The metal sleeve 2 can be a sleeve made of pure metal, or an electroplated sleeve with a metal layer plated on a hard plastic surface. The metal sleeve 2 can be a hollow structure or a solid structure. As long as one end is fixed to the conductive fiber bundle 1 and the other end is fixed to the bolt 3, it falls within the protection scope of the present invention.

[0027] In this embodiment, the above-mentioned touch brush head further includes a handle (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com