Electric reactor coil of multi-section structure

A reactor and segment structure technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of large partial discharge and large interlayer voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

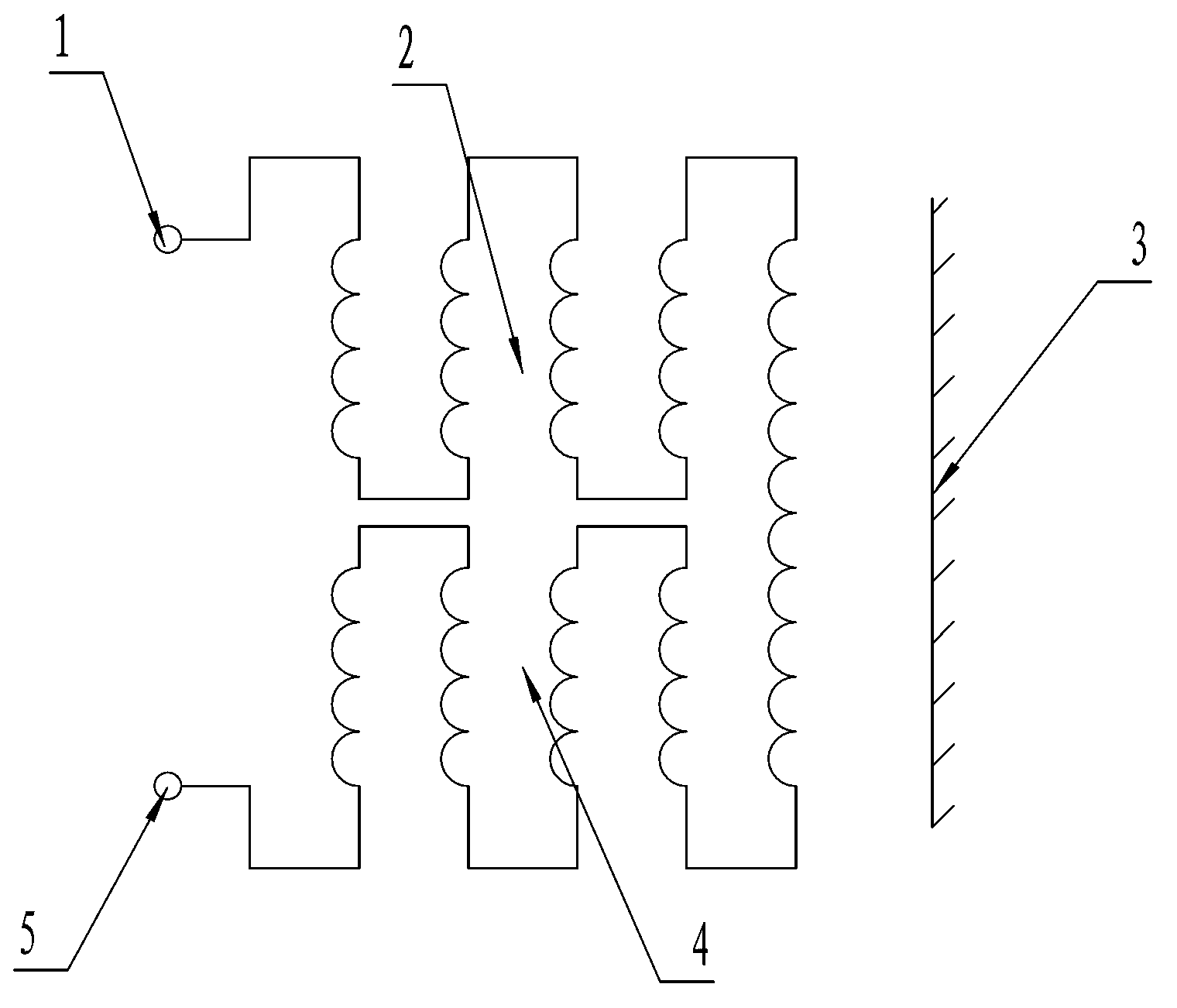

[0010] Embodiment 1, a multi-segment structure reactor coil, including coils wound on the core 3, is characterized in that: each continuously wound coil is evenly divided into two coil segments, the first segment coil 2, the second segment coil 3. Each coil segment is formed by continuous winding of at least three layers of coils.

Embodiment 2

[0011] Embodiment 2, a reactor coil with a multi-segment structure, including coils wound on the core 3, is characterized in that each continuously wound coil is evenly divided into three coil segments, the first segment coil, the second segment coil, The third section of coil, each coil section is formed by continuous winding of at least three layers of coils.

[0012] The winding method of the reactor coil with multi-section structure is characterized in that: standardize the position of the lead wire and the size of each section of the coil on the mold or insulating cylinder according to the drawing, the winding sequence is to wind the odd number of sections first, and turn the mold 180 degrees after winding After re-fixing, wind the even-numbered segments, and effectively connect each segment, and wind the longitudinal insulation and end insulation at the same time when winding the wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com