Novel railboat for diffusing silicon wafers

A quartz, a new type of technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems affecting battery efficiency, affecting the uniformity of diffusion, incompatibility between quartz boats and diffusion equipment, etc., to achieve battery High efficiency and the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

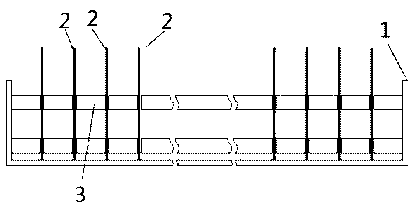

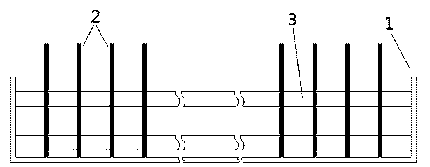

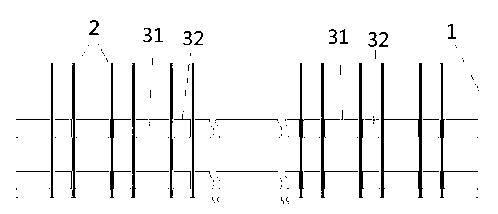

[0028] refer to image 3 , the specific embodiment adopts the following technical solutions: a new type of quartz boat for diffusion, which is used to place silicon wafers 2, which includes a boat body 1, and the boat body 1 is provided with at least three slots for placing silicon wafers 3. The distance between a certain card slot and the adjacent card slot is L1 and L2 respectively, where L1>L2 or L1

[0029] The present invention designs several sets of L1 and L2 unequal width intervals, the number of slots 3 increases but the total length of the boat body 1 of the quartz boat remains basically unchanged, so that the compatibilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com