Soil resistant floor cleaner

A technology of anti-fouling agent and anti-slip agent, which can be applied in the direction of anti-fouling/underwater coating, detergent compounding agent, detergent composition, etc., and can solve the problems of reducing the appearance of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

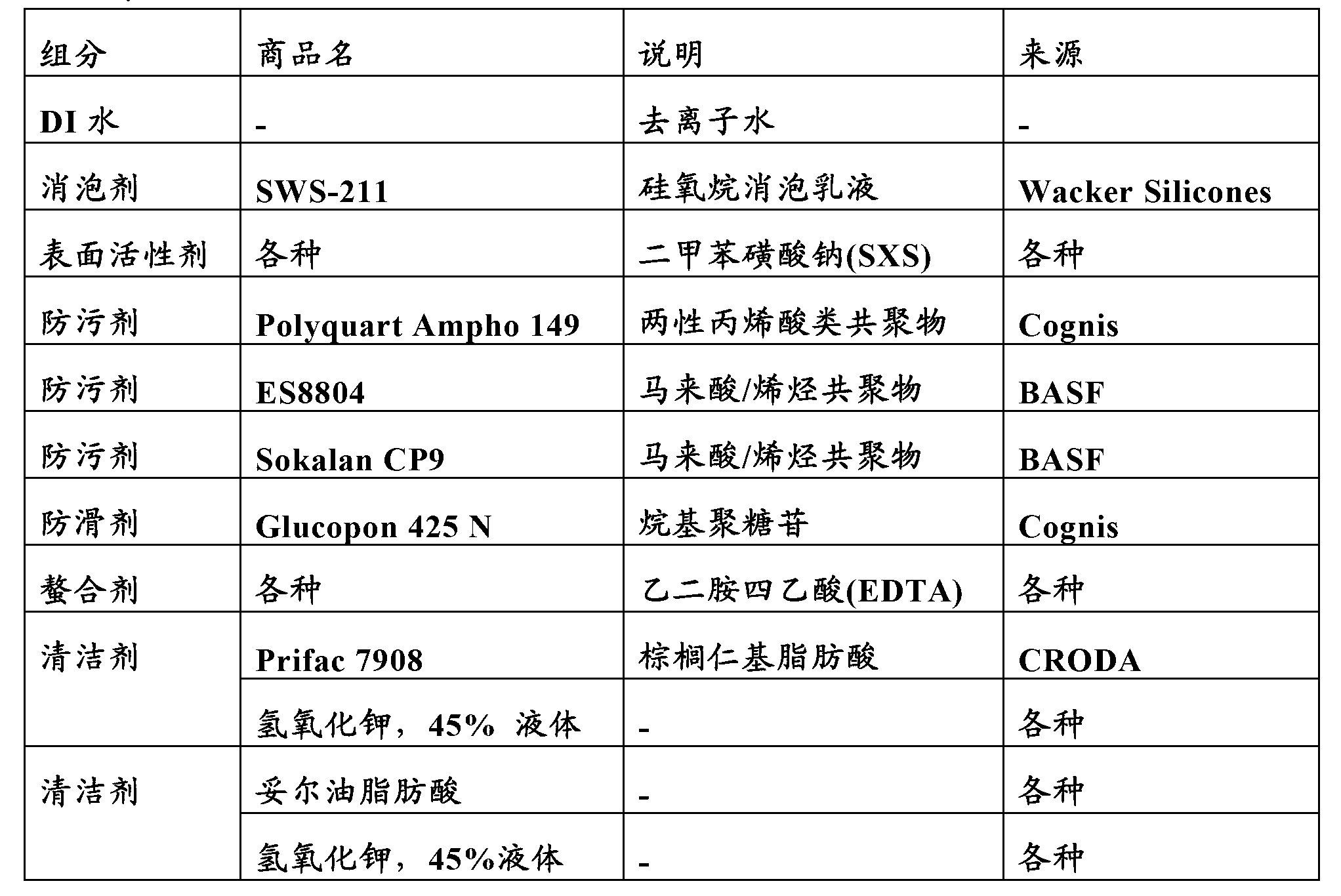

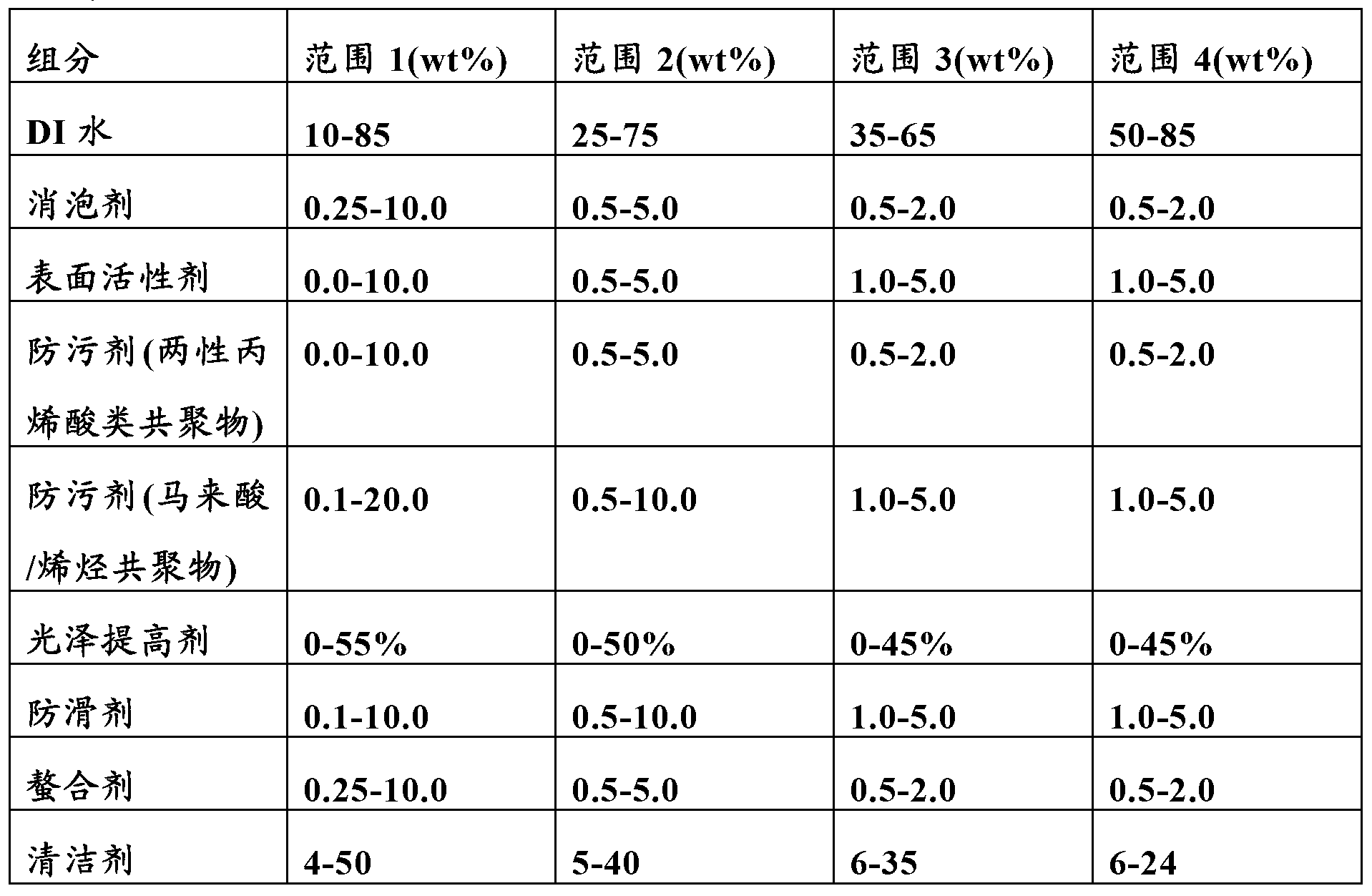

Method used

Image

Examples

Embodiment 1 and 2

[0110] Embodiment 1 and 2 and comparative example A

[0111] Examples 1 and 2 are compositions of the present invention that improve surface gloss. In particular, the compositions of Examples 1 and 2 contained a mixture of StoneMedic DCC (a cleaner) and MarketStar (a floor finish). Add the ingredients together and mix to form a homogeneous mixture.

Embodiment 3 and 4

[0130] Examples 3 and 4 are inventive compositions for increasing the slip resistance of surfaces. The compositions of Examples 3 and 4 were similar to the compositions of Examples 1 and 2, except that the compositions of Examples 3 and 4 contained an anti-slip agent instead of a gloss enhancing agent. In particular, the compositions of Examples 3 and 4 included StoneMedic DCC (a cleanser), and StoneMedic Anti-Slip Treatment (an anti-slip agent). Mix the ingredients together to form a homogeneous mixture.

[0131] A composition of StoneMedic DCC was used as Comparative Example A.

[0132] Table 4 provides the component concentrations of the compositions of Examples 3 and 4 and Comparative Example A.

[0133] Table 4

[0134] components

Example 3 (wt%)

Example 4 (wt%)

Comparative example A (wt%)

StoneMedic DCC

98

97

100

StoneMedic anti-slip treatment

2

3

0

[0135] The compositions of Examples 3 and 4 and Com...

Embodiment 5

[0139] Examples 5, 6, 7, 8 and 9

[0140] Examples 5, 6, 7, 8 and 9 are compositions evaluated for gloss enhancement. The compositions of Examples 5-9 contained the component concentrations (weight percent) of water, oleic acid, monoethanolamine (MEA), Hostapur SAS, Belclene 283 and Morglo 8 provided in Table 6. Add the ingredients together and mix to form a homogeneous mixture.

[0141] The composition of Example 1 was shown to function effectively as a gloss enhancer, and the composition of Example 1 was used as a control. The composition of Example 1 comprised 98 wt% StoneMedic DCC and 2 wt% MarketStar and had a pH of 9.77.

[0142] Table 6 provides the component concentrations of the compositions of Examples 1, 5, 6, 7, 8 and 9 and the pH of each composition.

[0143] Table 6

[0144]

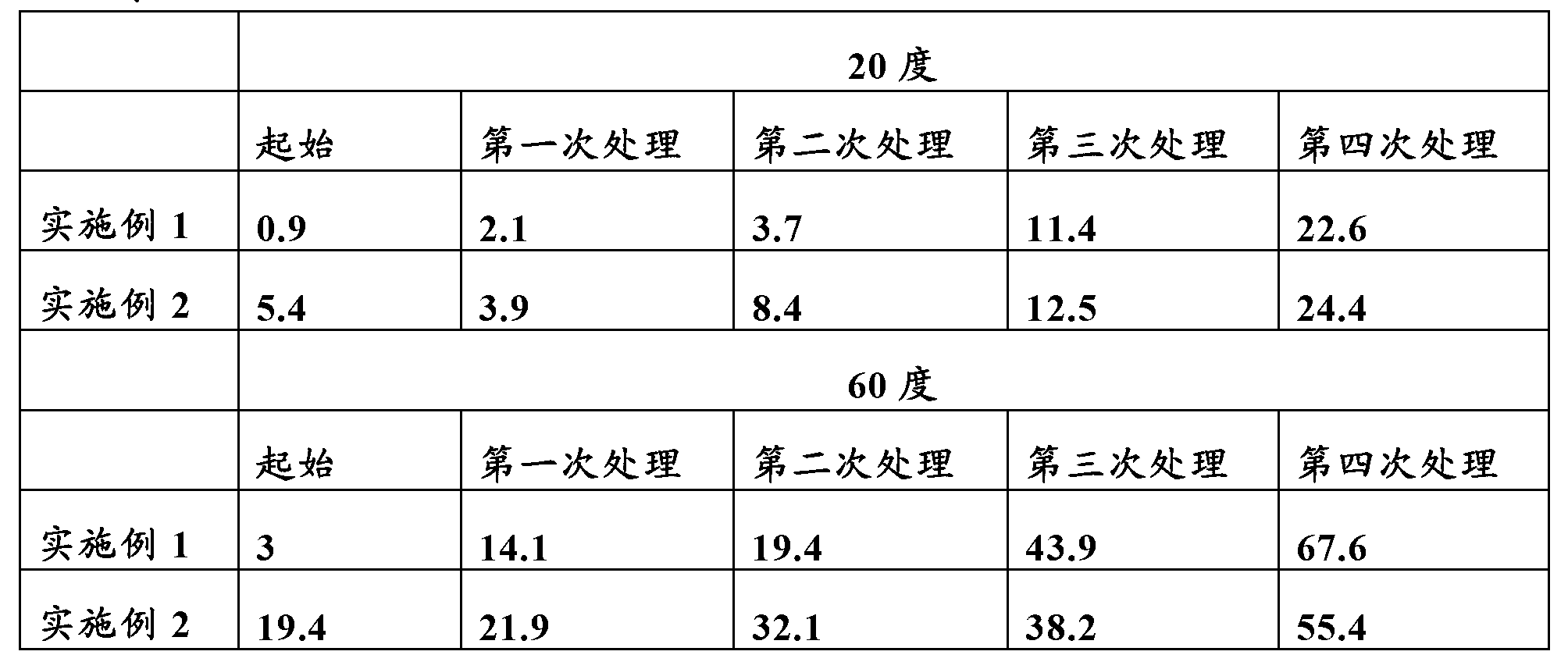

[0145] At the beginning and in use obtained from The compositions of Examples 5-9 and Example 1 were measured at about 20 degrees and 60 degrees after each of three cleaning treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com