Compressor motor and electric compressor using same

一种电动压缩机、电动机的技术,应用在机器/发动机、机电装置、电动组件等方向,能够解决电动机电线束长度变长等问题,达到缩短导线长度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

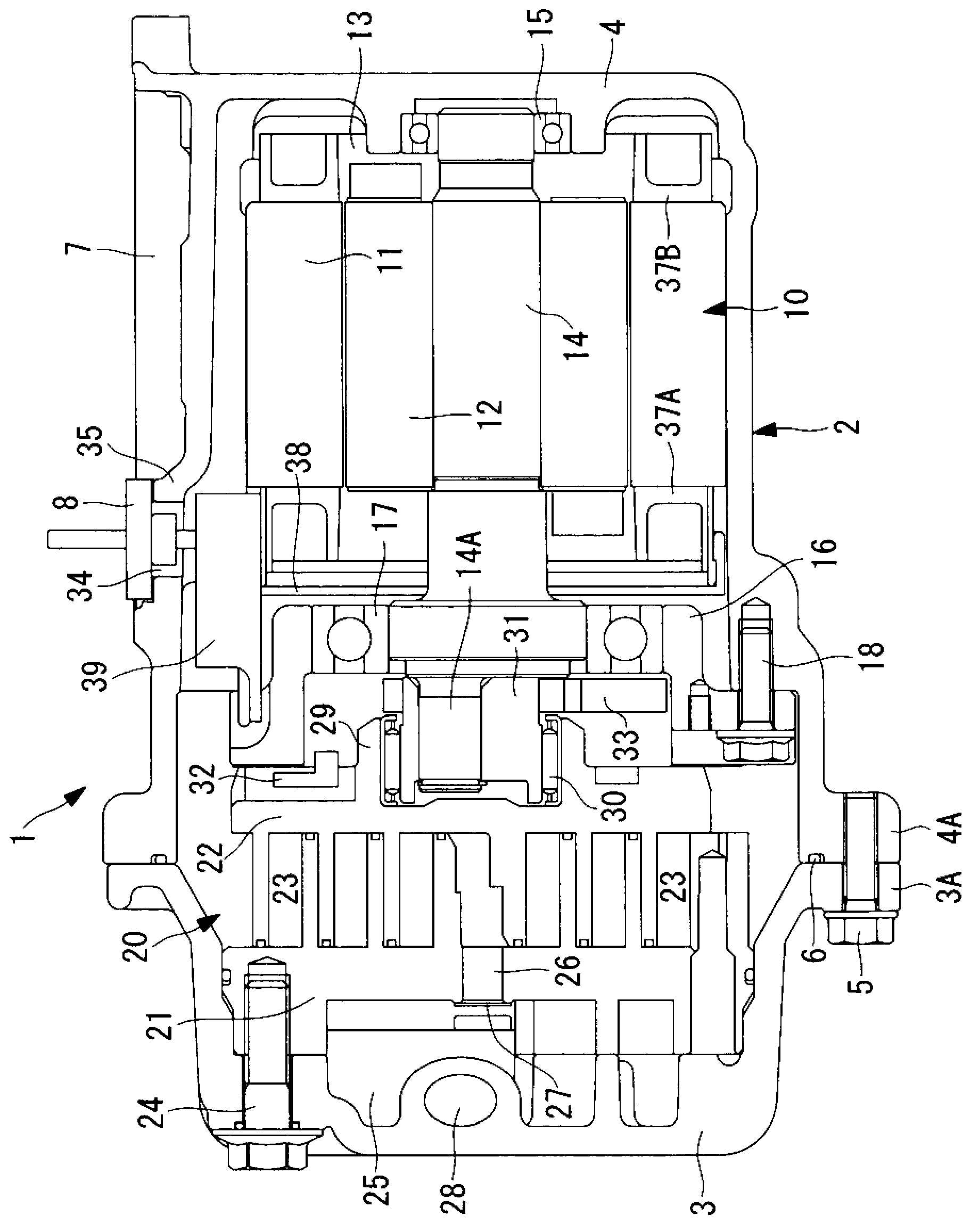

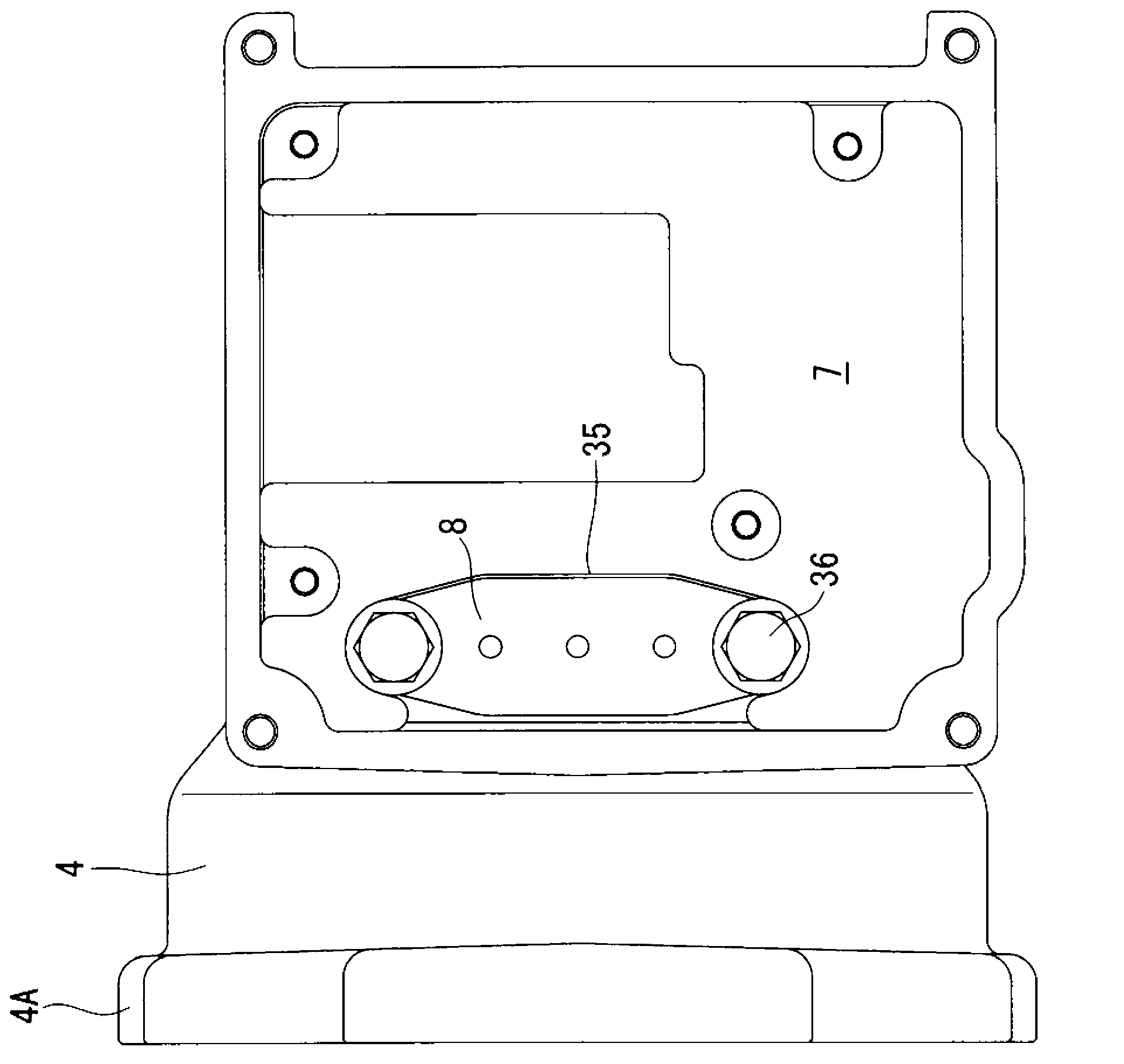

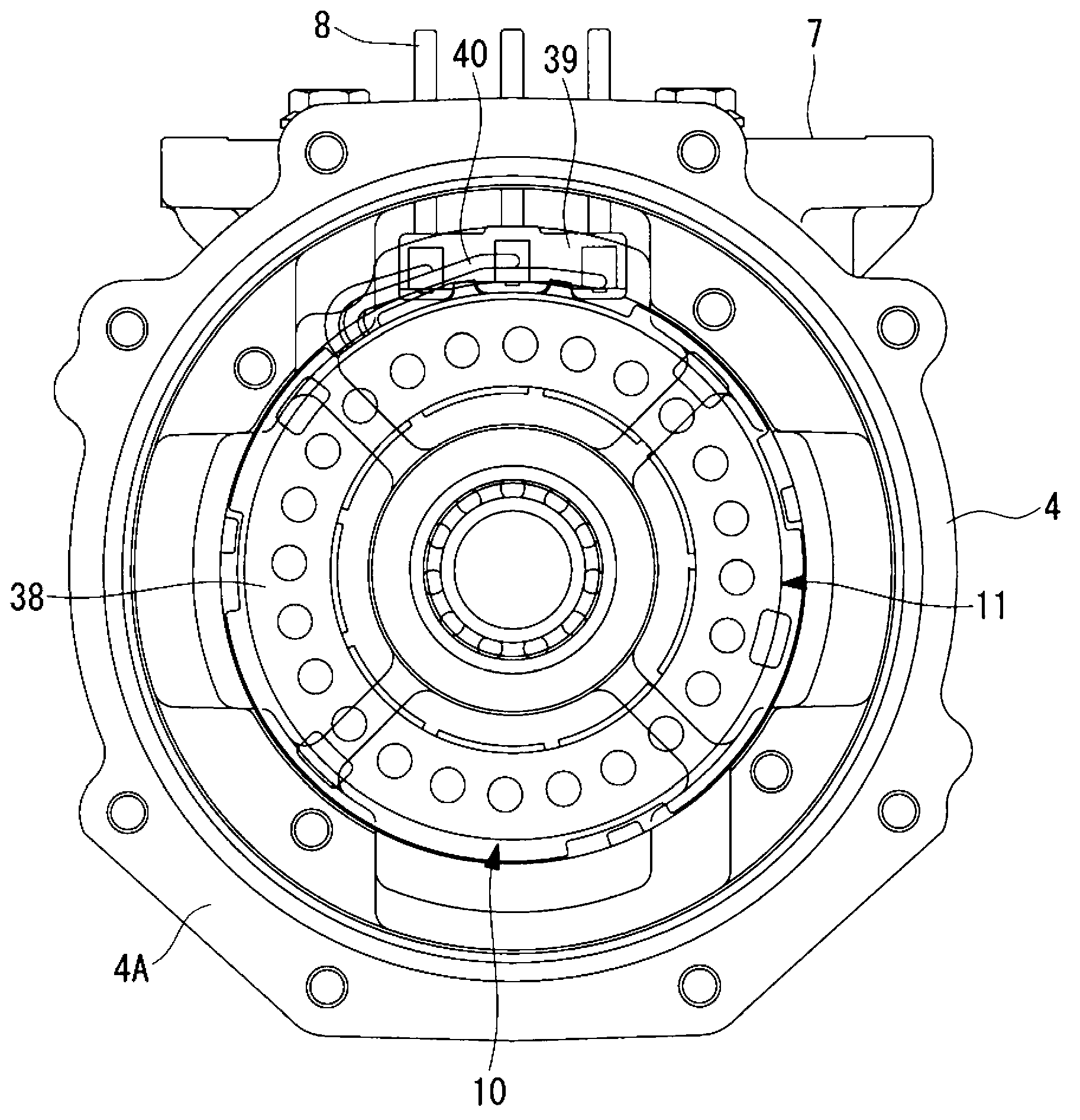

[0071] Below, use figure 1 The first embodiment of the present invention will be described with reference to FIG. 8 .

[0072] figure 1 A longitudinal sectional view showing an electric compressor according to an embodiment of the present invention without an inverter unit, figure 2 A plan view showing the motor side of the compressor, image 3 It shows the front view of the compressor motor side viewed from the compression mechanism side, Figure 4 A longitudinal sectional view showing the compressor motor side.

[0073] In this embodiment, a scroll type electric compressor 1 is illustrated as the electric compressor 1 . The electric compressor 1 has a cylindrical casing 2 constituting an outer casing. The casing 2 includes: a compressor casing 3 which is a cylindrical aluminum die-casting part with a bottom; solid and made into an integrated structure.

[0074] An inverter housing portion 7 is integrally provided on the outer periphery of the motor case 4 . In this ...

no. 2 approach

[0111] Next, a second embodiment of the present invention will be described.

[0112] This embodiment differs from the first embodiment described above in that a block 39 is provided on the bobbin 37A at the coil end of the stator 11 . Others are the same as those of the first embodiment, and description thereof will be omitted.

[0113] That is, in the present embodiment, the outer peripheral portion of the bobbin 37A on the side of the compression mechanism 20 among the pair of bobbins 37A, 37B provided at the coil ends of the stator 11 of the motor 10 uses the same arrangement as that of the first embodiment. The block 39 is constructed or provided by being sandwiched between the bobbin 37A and the stator coil end case 38 .

[0114] The bobbin 37A is made of an insulating resin material as described above, and claws etc. are integrally formed thereon, so that the block 39 can be locked, and the block 39 can be arranged in the circumferential direction and / or the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com