Hydraulic drive gearbox for harvesting machine

A technology for harvesting machinery and gearboxes, applied in the field of hydraulically driven gearboxes, which can solve the problems of inability to bring comfortable operating environment to drivers, high requirements for operating skills and physical fitness, limited cab space, etc., and achieve novel structural design and comfortable operation Environment, the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

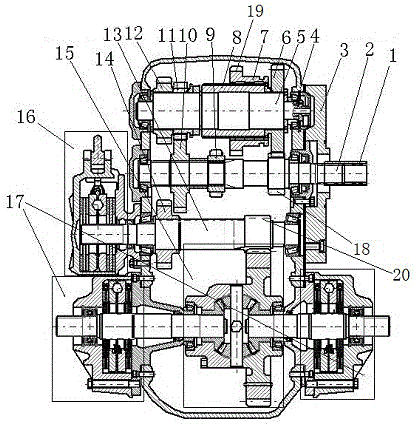

[0009] The present invention is realized in this way, it includes coupling sleeve 1, gearbox input shaft 2, input housing 3, gearbox housing 4, intermediate shaft 5, first gear driven gear 6, gear sleeve 7, gear hub 8, Second gear driving gear 9, third gear driving gear 10, third gear driven gear 11, intermediate shaft driving gear 12, driven shaft 13, driven shaft driven gear 14, differential mechanism 15, hand brake mechanism 16, foot brake Mechanism 17, first gear driving gear 18, second gear driven gear 19 and driven shaft driving gear 20, its structural feature is that the left end of the gearbox input shaft 2 is connected on the left side inner wall of the gearbox housing 4, and the gearbox input shaft The right end of 2 is located outside the right side of the gearbox housing 4, the right end of the gearbox input shaft 2 is connected with a coupling sleeve 1, and the right side of the gearbox input shaft 2 is fixed on the gearbox housing 4 through the input housing 3, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com