Prestress-reinforced light high-strength controllable-degradation medical composite material and preparation method thereof

A composite material and prestressing technology, applied in medical science, surgery, etc., can solve the problems of non-degradable absorption, low strength, and large difference between elastic modulus and cortical bone, so as to limit the generation and expansion of cracks and improve shear resistance and torsion resistance, reducing the effect of stress shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

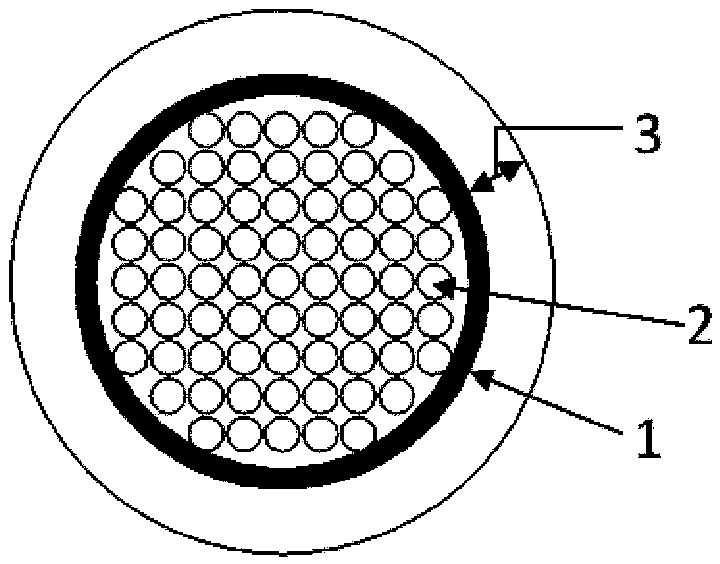

[0034] The selected polymer matrix is PLLA polylactic acid with a molecular weight of 160,000 to 200,000; the composition of the magnesium alloy wire is AZ31B, the yield strength is 220MPa, the diameter is 0.32mm, and the volume fraction is 5%, 10%, and 20%; The ribs are the same as the reinforced magnesium alloy wire.

[0035] Perform micro-arc oxidation treatment on the surface of the magnesium alloy wire, use 10g / L sodium silicate, 2g / LNaOH and 10g / L hydroxyapatite nanoparticles as the micro-arc oxidation electrolyte system, and immerse the magnesium alloy wire in it, Apply a voltage of 400V and perform micro-arc oxidation treatment for 10 minutes to form a ceramic protective layer rich in magnesium oxide, magnesium silicate and hydroxyapatite in situ on the surface.

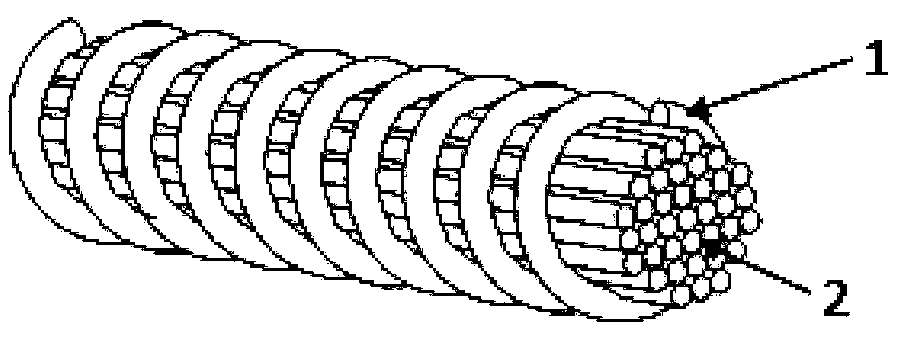

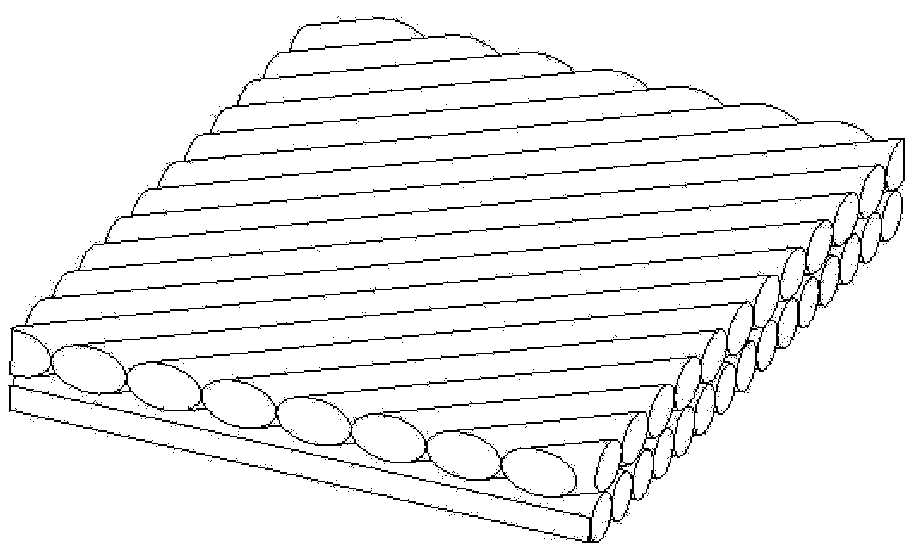

[0036] Magnesium alloy wires are oriented parallel to the axial direction of the composite material, and then tensile stress is applied to both ends, and then the stirrups are bound (see attached Figure 4...

Embodiment 2

[0042] PLA and PGA copolymer PLGA is selected as the polymer matrix. Relevant studies have shown that the degradation half-life of PLGA is related to the content of PGA: when the PGA content is less than 20%, the degradation half-life decreases significantly with the increase of the content; the content is 20% to 80%. %, the degradation half-life first decreases slowly, reaches the minimum at 50%, and then increases slowly; after exceeding 80%, the degradation half-life increases rapidly again. The PLGA selected in this example is synthesized by copolymerization of 15% PGA and 85% PLA, with a molecular weight of 150,000 to 200,000; the diameter of the magnesium alloy wire is 0.8 mm, the composition is MB8, the yield strength is 170 MPa, and the volume fraction is 9 %; The stirrup material and surface treatment method are the same as the reinforced magnesium alloy wire, with a diameter of 0.5mm.

[0043] Phosphate treatment on the surface of magnesium alloy wire, the solution i...

Embodiment 3

[0050] The selected polymer matrix is a blend copolymer of polylactic acid-polycaprolactone (PLA-PCL); the magnesium alloy wire is QE22, with a diameter of 0.5mm and a volume fraction of 20%; stirrups and reinforced magnesium alloy wire same. Use 10g / L sodium silicate, 3g / L hydroxyapatite nanopowder, and 2g / LNaOH as the micro-arc oxidation electrolyte system, immerse the magnesium alloy wire in it, apply a voltage of 400V, and perform micro-arc oxidation for 15 minutes treatment to generate magnesium oxide and hydroxyapatite composite ceramic protective layer on the surface in situ.

[0051] Magnesium alloy wires are oriented parallel to the axial direction of the composite material, and then tensile stress is applied to both ends. The tensile stress is 20% of the yield strength of the magnesium alloy wires, and then the stirrups are tied. The alloy wires are fixedly arranged in the cavity of the mould. The polymer solution in the molten state is injected into the mold cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com