Dyeing device for textile fabric

A technology for textile fabrics and material blocks, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of high printing and dyeing price, high price, long production cycle, etc., and achieve the effect of easy use, low cost, and convenient printing and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

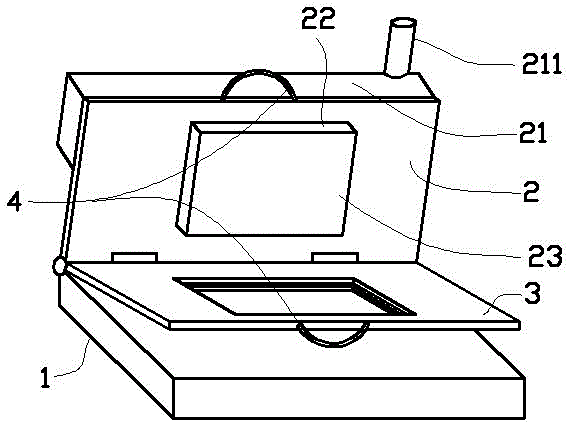

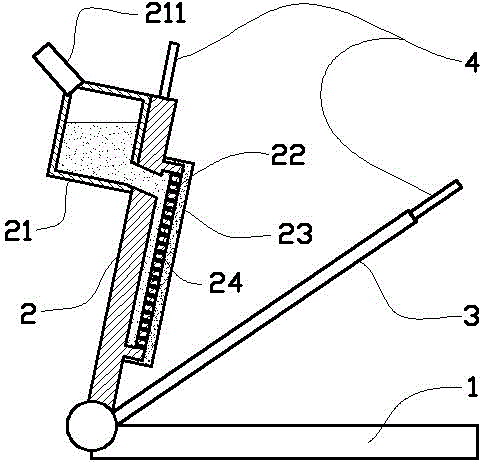

[0014] Such as figure 1 and figure 2 As shown in the embodiment, the textile fabric printing and dyeing device includes a placement base plate 1, a printing and dyeing cover plate 2 hinged on the top of the placement base plate, and a template frame 3 hinged between the placement base plate 1 and the printing and dyeing cover plate 2 The top of the printing and dyeing cover plate 2 is fixed with a paint box 21, and the bottom of the printing and dyeing cover plate 2 is fixed with a raised discharge block 22, and the bottom of the discharge block 22 is a plane, wrapped with a sponge body 23; Evenly distributed liquid outlet holes 24 are processed on the lower plane of the discharge block 22, and the liquid outlet holes 24 communicate with the inner cavity of the paint box 21, and a printing and dyeing template is installed in the middle of the template frame 3.

[0015] The textile fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com