Rapid printing device for textiles

A textile and fast technology, applied in printing devices, printing, printing machines, etc., can solve the problems of inconvenient printing and dyeing, low pass rate of printing and dyeing, etc., and achieve the effects of improving work efficiency, avoiding damage, improving work efficiency and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

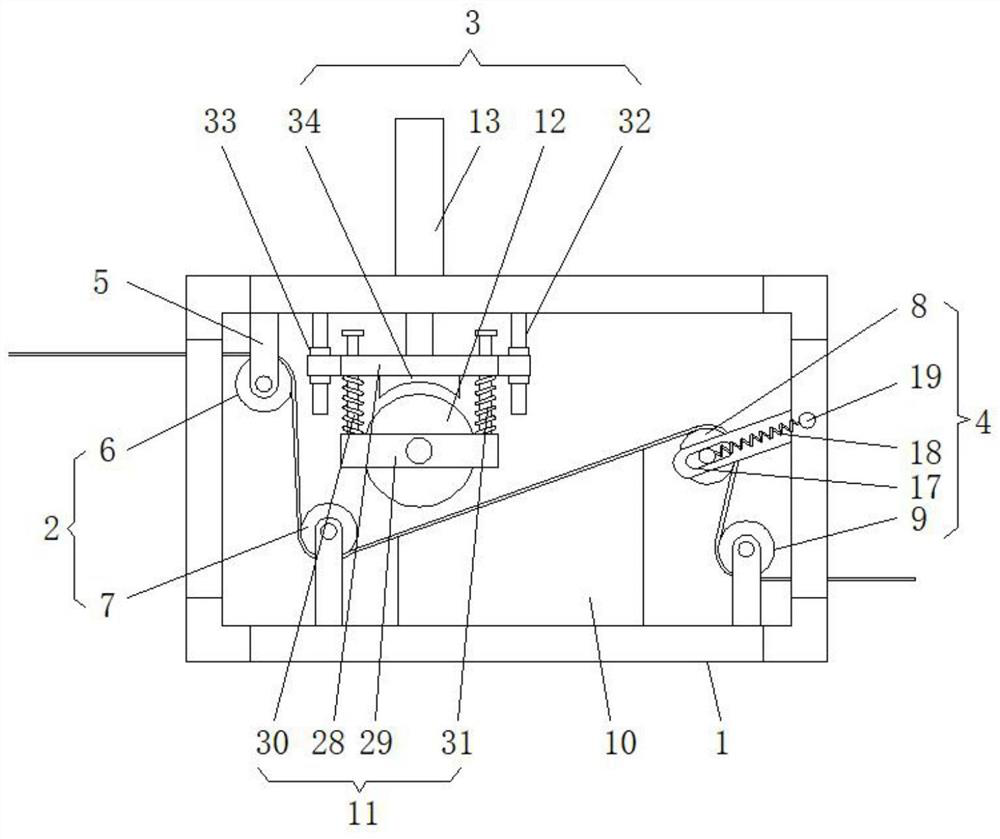

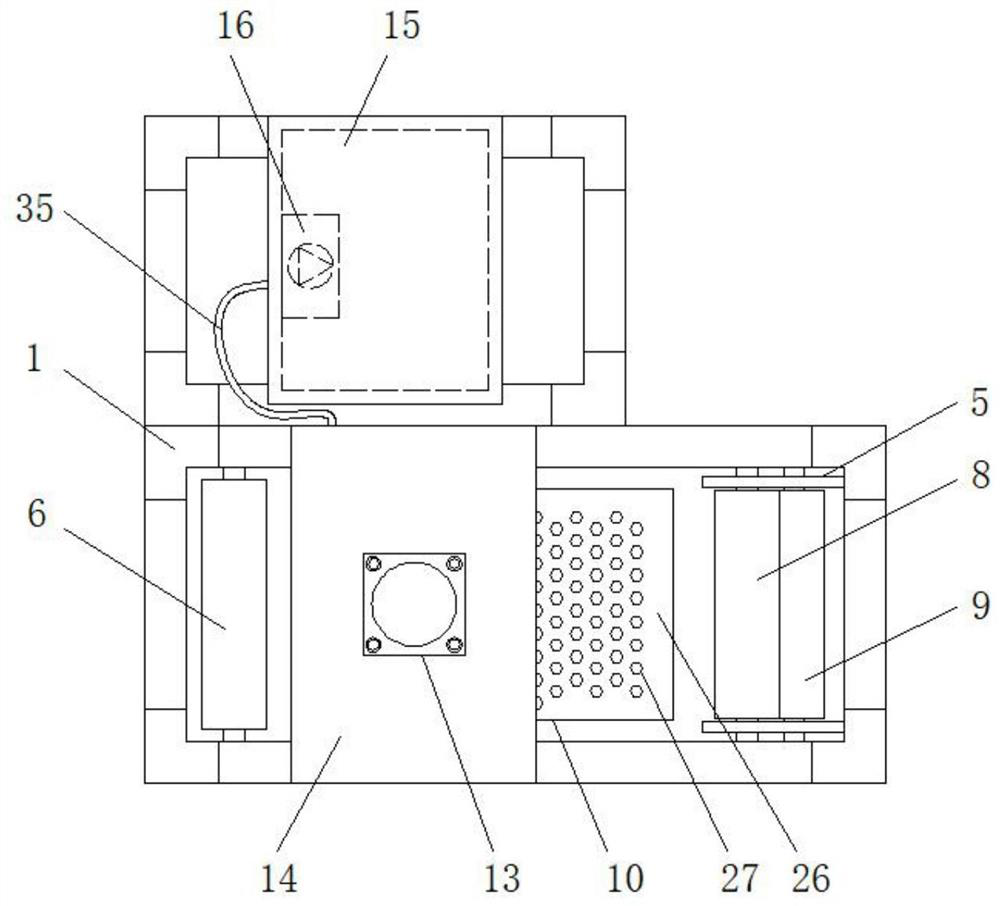

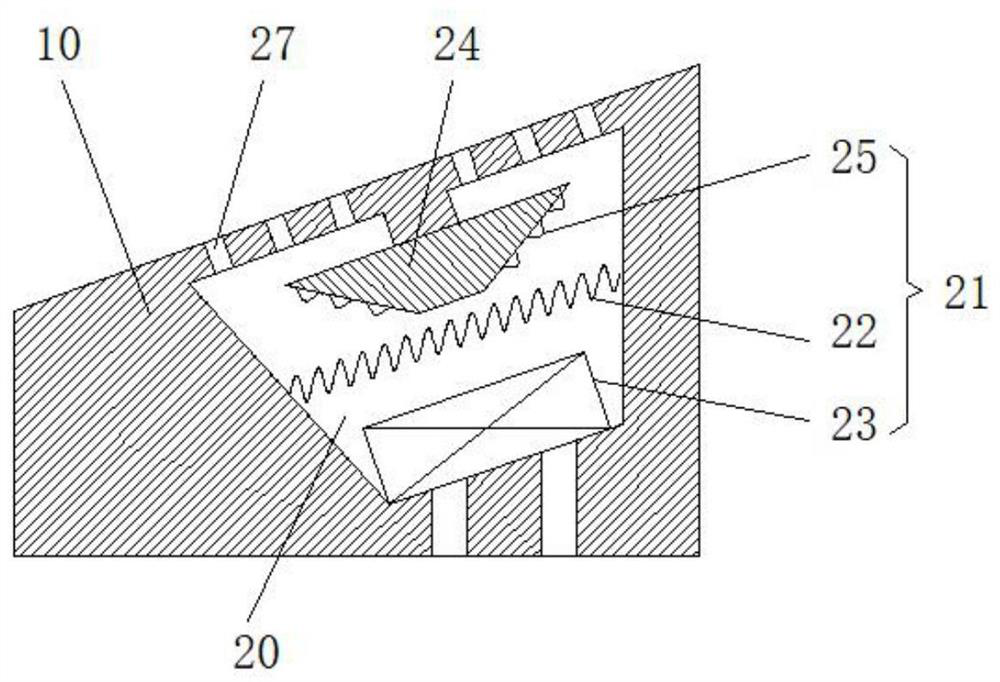

[0033] When the present invention is working, the textile cloth is fed into the printing and dyeing mechanism 3 along the feed roller group 2 and discharged from the discharge roller group 4, and the hydraulic rod 13 pushes the printing and dyeing frame 11 to move downward, so that the printing and dyeing roller 12 is closely attached to the surface of the textile cloth , as the movement of the textile cloth drives the printing and dyeing roller 12 to rotate, the printing and dyeing roller 12 transfers the pattern on its surface to the surface of the textile cloth, and the printed textile cloth continues to move along the surface of the printing and dyeing table 10 to the air outlet 27, and the fan 23 will The heat generated by the thermal resistance wire 22 is blown to the surface of the textile fabric, which facilitates rapid drying of the dyes on the surface of the textile fabric, and improves the working efficiency and printing quality of the printing and dyeing process.

Embodiment 2

[0035] When the present invention is carrying out printing and dyeing processing, the pump body 16 in the dye tank 15 regularly sends the dye to the painting pad 34 under the control of the relay, so as to ensure the painting efficiency of the painting pad 34 on the printing and dyeing roller 12, and the painting pad 34 The dye inside is fully absorbed by the sponge pad 37, and the dye is evenly coated on the surface of the printing and dyeing roller 12 when the printing and dyeing roller 12 rotates, thereby ensuring that the printing and dyeing roller 12 quickly prints and dyes the textile cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com