Disazo reactive yellow dye and its preparation method and application

A technology of reactive yellow and disazo, applied in reactive dyes, azo dyes, dyeing methods, etc., can solve the problems of unfavorable environmental protection, high pollution, etc., reduce the use of inorganic salts, high reactivity, avoid heavy metals and carcinogenicity The effect of aromatic amine exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

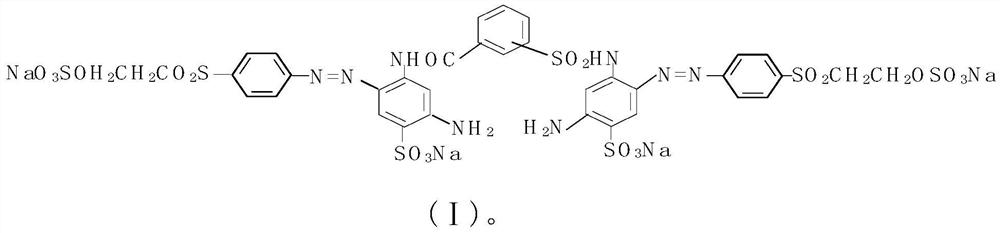

[0034] A kind of disazo reactive yellow dye, its structural formula is as (I)-1:

[0035]

[0036] The disazo reactive yellow dye is tested by the domestic reactive golden yellow RNL as a standard. The shade is reddish and brilliant, and the strength is 215%. It is suitable for exhaust dyeing, continuous dyeing and printing of cellulose fibers.

[0037] The present embodiment also provides the preparation method of this disazo active yellow dye, comprising the following steps:

[0038] a. Add sodium m-bisaminobenzenesulfonate with a purity of 80% and a percent weight of 126.12g to 1000ml of water, raise the temperature to 35°C under stirring, then add 100g of sodium chloride, keep the pH=7.2, and stir for 30min until solid The substance dissolves to obtain a clear solution;

[0039] b. Control the temperature at 35°C, add m-chlorosulfonylbenzoyl chloride with a percent weight of 76g to the clear solution obtained in step a at a uniform speed within 2h, carry out the acylat...

Embodiment 2

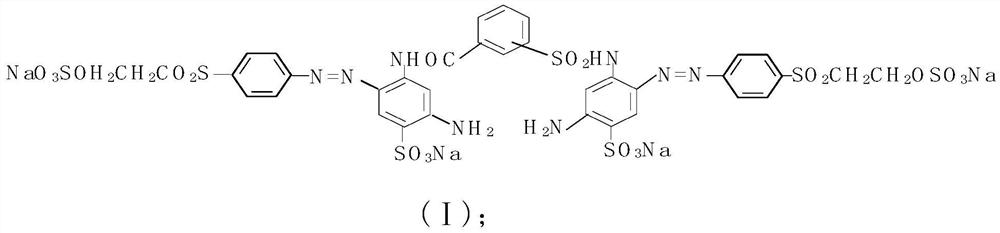

[0047] A kind of disazo reactive yellow dye, its structural formula is as (I)-1:

[0048]

[0049] This example also provides the preparation method of the disazo reactive yellow dye, which differs from Example 1 in that in step b, the temperature is controlled at 37° C. during the acylation reaction.

[0050] After testing, the analytical content of meta-bisacylate obtained in the process of preparing disazo reactive yellow dye in this example is ≧69.1%, HPLC purity ≧95.5%, meta-bis ≤0.76%, bis-acylated meta-bis ≤1.75%, others ≤2%.

Embodiment 3

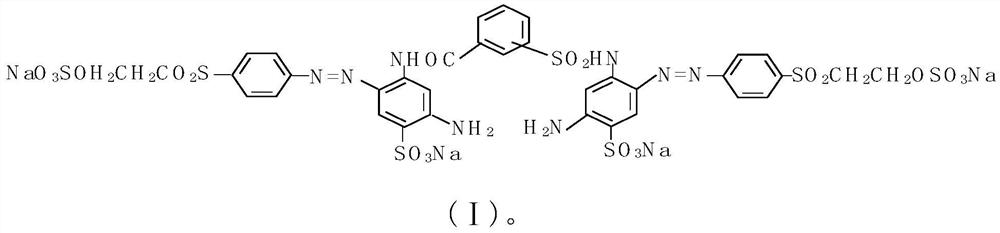

[0052] A kind of disazo reactive yellow dye, its structural formula is as (I)-1:

[0053]

[0054] This example also provides the preparation method of the disazo reactive yellow dye, which differs from Example 1 in that in step b, the temperature is controlled at 40° C. during the acylation reaction.

[0055] After testing, the analysis content of meta-bisacylate obtained in the process of preparing disazo reactive yellow dye in this example is ≧69.3%, HPLC purity ≧95.1%, meta-bis ≤0.74%, bis-acylated meta-bis ≤1.78%, others ≤1.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com