Magnetic transmission type tire pressure sensor, setting tool and setting method

A tire pressure sensor and tool technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve problems such as power consumption, large transmission power, and complex demodulation circuit, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

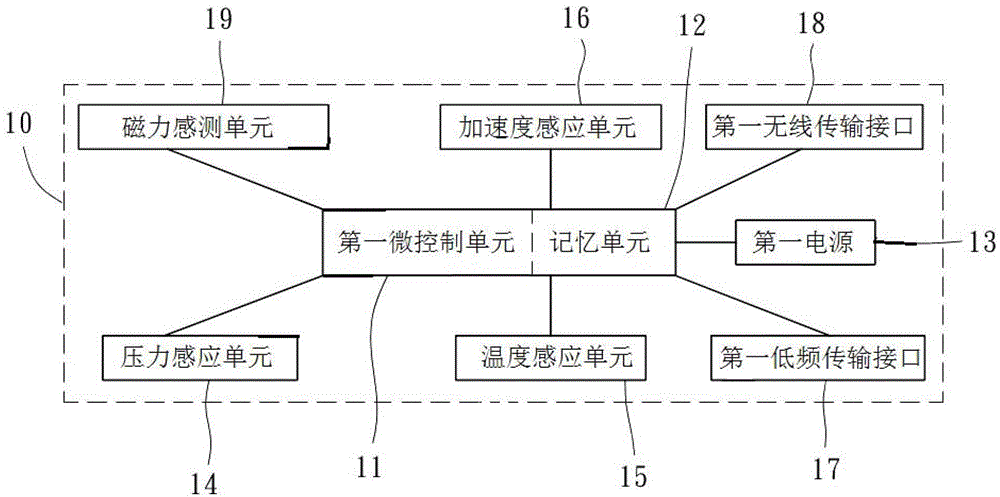

[0052] figure 1 It is a functional block diagram of the tire pressure sensor of the present invention. Such as figure 1 As shown, this embodiment proposes a tire pressure sensor 10, including:

[0053] a first microcontroller unit 11;

[0054] A memory unit 12, the memory unit 12 is connected to the first micro control unit 11 by telecommunication;

[0055] A first power supply 13 for providing power required by the tire pressure sensor 10, the first power supply 13 is connected to the first micro control unit 11 by telecommunication;

[0056] A pressure sensing unit 14 for measuring the air pressure in the tire, the pressure sensing unit 14 is connected to the first micro control unit 11 by telecommunication;

[0057] A temperature sensing unit 15 for measuring the temperature inside the tire, the temperature sensing unit 15 is connected to the first micro control unit 11 by telecommunication;

[0058] An acceleration sensing unit 16 for measuring tire acceleration, the ...

Embodiment 2

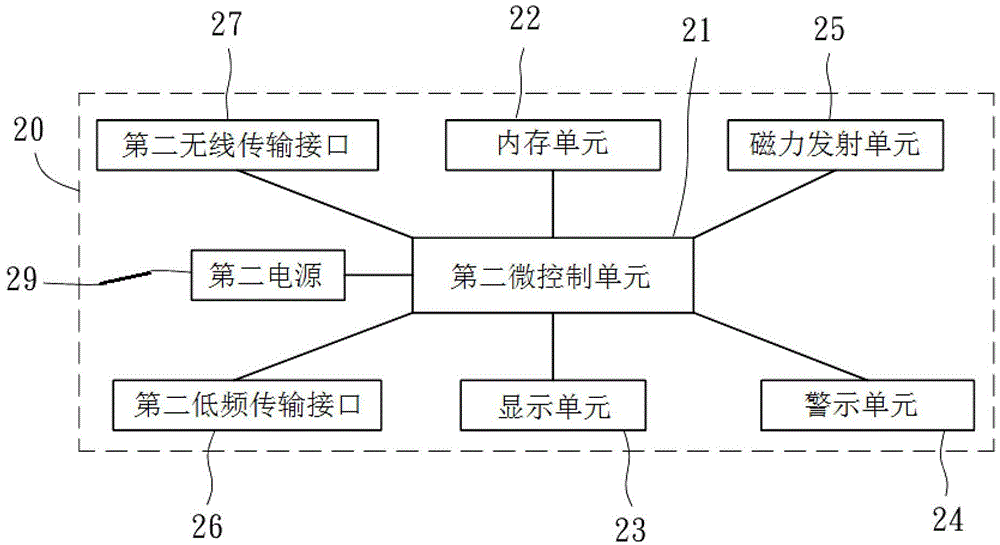

[0063] figure 2 A functional block diagram of the setting tool for the present invention. Corresponding to the tire pressure sensor 10, the present invention also includes a setting tool 20 to cooperate with the tire pressure sensor 10, such as figure 2 As shown, the setting tool 20 includes:

[0064] a second micro control unit 21;

[0065] A memory unit 22 for storing the ID (Identification) and communication protocol data of the tire pressure sensor 10, the memory unit 22 is connected to the second micro control unit 21 by telecommunication;

[0066] A display unit 23 for displaying the operation information of the setting tool 20, the display unit 23 is connected to the second micro control unit 21 by telecommunication;

[0067] A magnetic force emission unit 25 for emitting magnetic force lines, the magnetic force emission unit 25 is connected to the second micro-control unit 21 by telecommunication, exemplary, the magnetic force emission unit 25 of this embodiment i...

Embodiment 3

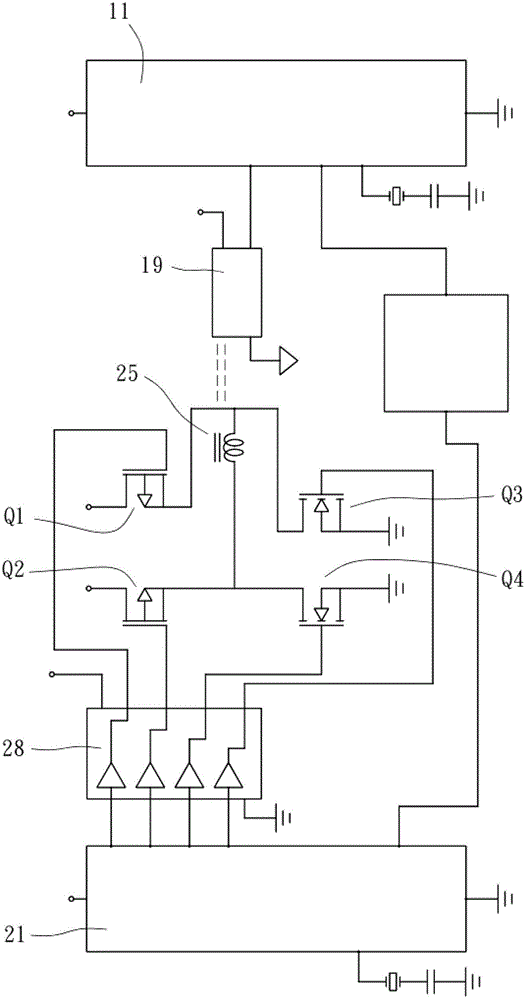

[0074] As shown in the drawings, through the structure of the tire pressure sensor 10 of the first embodiment and the setting tool 20 of the second embodiment, the setting method of the tire pressure sensor of the present embodiment is as follows:

[0075] First provide the tire pressure sensor 10 in the first embodiment, and the setting tool 20 in the second embodiment; After the second micro-control unit 21 codes, the magnetic force transmitting unit 25 transmits the control program to the magnetic sensing unit 19 of the tire pressure sensor 10 to receive; finally the first micro-control unit 11 of the tire pressure sensor 10 is reading the magnetic force After the waveform output by the measuring unit 19, the original control program is restored and stored in the memory unit 12.

[0076] As shown in FIG. 3 , it is a schematic circuit diagram of the setting tool 20 and the tire pressure sensor 10 in the present invention. Specifically, the second micro-control unit 21 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com