Hot-melt and pressure sensitive plaster matrigel

A plaster base, hot-melt technology, applied in the directions of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc. Strong, large drug loading, good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

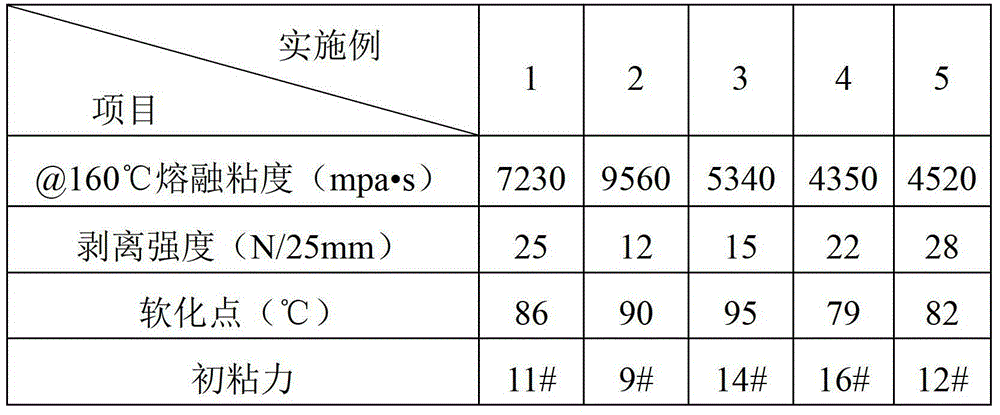

Examples

Embodiment 1

[0018] Embodiment 1: a kind of hot-melt pressure-sensitive plaster base glue and preparation thereof

[0019] Take the following components by weight: thermoplastic elastomer SIS200g, thermoplastic elastomer SBS50g, thermoplastic elastomer SEPS50g, C5 / C9 copolymerized petroleum resin 100g, C5 petroleum resin 100g, rosin resin 300g, food grade carmine 50g, naphthenic oil KNH4010200g , Antioxidant is BHT26410g.

[0020] The thermoplastic elastomer SIS, thermoplastic elastomer SBS, thermoplastic elastomer SEPS, naphthenic oil KNH4010 were added to the reaction kettle at the same time, and the reaction kettle was stirred and melted for 60 minutes at a temperature of 130 ° C under the condition of nitrogen gas, and then Add C5 / C9 copolymerized petroleum resin, C5 petroleum resin, rosin resin, and food grade carmine into the reaction kettle, melt and mix at 140°C for 60 minutes, and finally add antioxidant to stir and mix BHT264. And vacuumize to remove air bubbles, discharge, cool...

Embodiment 2

[0021] Embodiment 2: a kind of hot-melt pressure-sensitive plaster base glue and preparation thereof

[0022] Take the following components by weight: thermoplastic elastomer SIS150g, thermoplastic elastomer SBS150g, thermoplastic elastomer SEPS50g, C5 / C9 copolymerized petroleum resin 100g, C5 petroleum resin 200g, rosin resin 150g, naphthenic oil KNH4010200g, antioxidant BHT26410g.

[0023] The thermoplastic elastomer SIS, thermoplastic elastomer SBS, thermoplastic elastomer SEPS, naphthenic oil KNH4010 were added to the reaction kettle at the same time, and under the condition of nitrogen gas, the reaction kettle was stirred and melted at a temperature of 150 ° C for 70 minutes, and then Add C5 / C9 copolymerized petroleum resin, C5 petroleum resin, and rosin resin into the reaction kettle, melt, stir and mix at 150 ° C for 70 minutes, finally add antioxidant, stir and mix, and vacuumize to remove air bubbles, discharge, and cool to form.

Embodiment 3

[0024] Embodiment 3: a kind of hot-melt pressure-sensitive plaster base glue and preparation thereof

[0025] Take the following components by weight: thermoplastic elastomer SIS50g, thermoplastic elastomer SBS50g, thermoplastic elastomer SEPS200g, C5 / C9 copolymerized petroleum resin 150g, C5 petroleum resin 150g, rosin resin 150g, food grade bright blue 25g, food grade lemon yellow 25g, naphthenic oil KNH4010250g, antioxidant BHT26410g.

[0026]The thermoplastic elastomer SIS, thermoplastic elastomer SBS, thermoplastic elastomer SEPS, naphthenic oil KNH4010 were added to the reaction kettle at the same time, and the reaction kettle was stirred and melted at a temperature of 150 ° C for 80 minutes under the condition of nitrogen gas. Add C5 / C9 copolymerized petroleum resin, C5 petroleum resin, rosin resin, food-grade bright blue, and food-grade tartrazine into the reaction kettle, melt, stir and mix at 160°C for 90 minutes, and finally add antioxidant BHT264, stir and mix, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap