Converter primary exhaust gas dry dedusting coarse ash pneumatic conveying method

A technology of pneumatic conveying and dry dust removal, which is applied in the manufacture of converters, etc., can solve the problems of stuck ash, uneven humidification of coarse ash, and occupying indoor space, so as to reduce the failure rate of equipment, reduce the amount of equipment maintenance, and reduce the number of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0024] The method for pneumatic conveying of crude ash from a converter's primary flue gas dry dust removal method of the present invention includes steps S1-S6, which are specifically as follows:

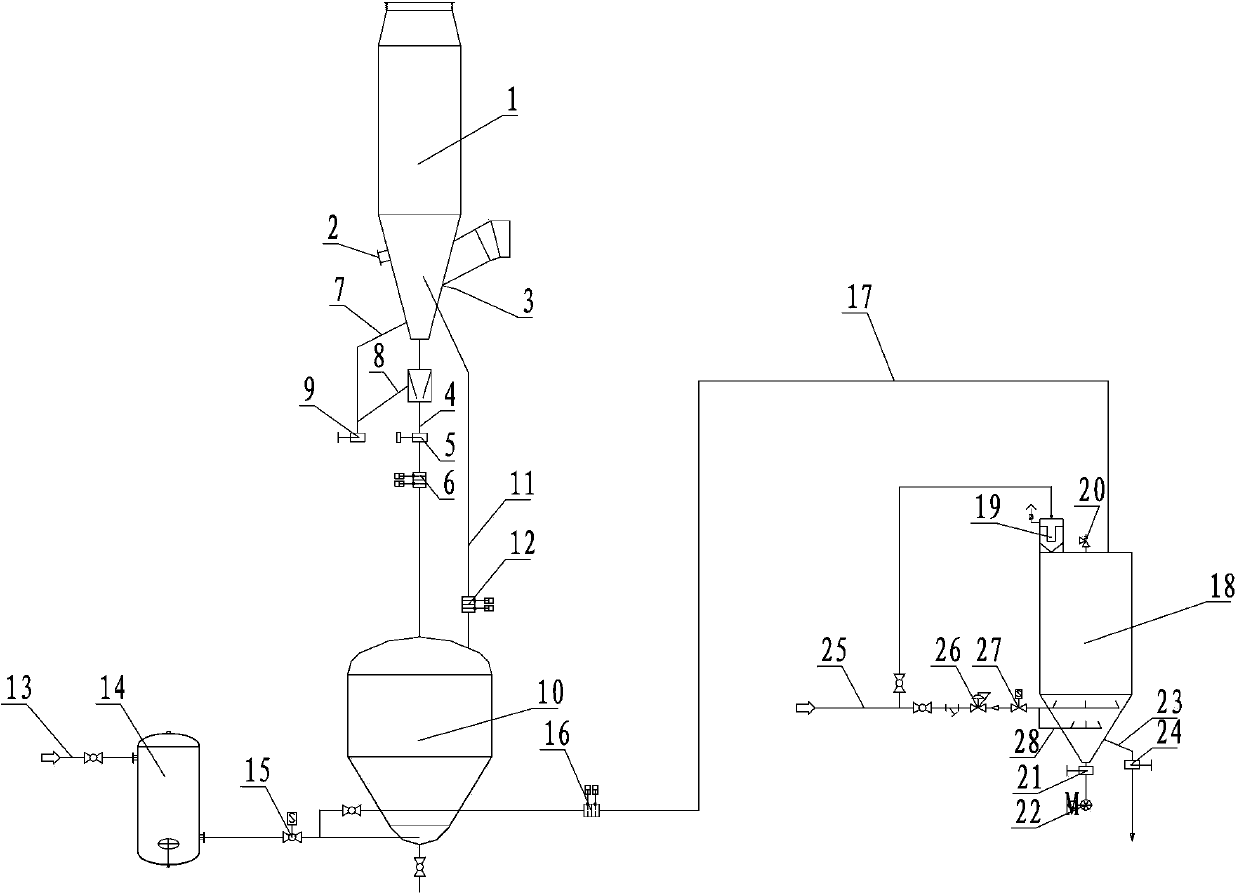

[0025] S1. Construct a pneumatic conveying system for the primary flue gas dry dust removal and coarse ash of the converter, such as figure 1 As shown, it includes an evaporative cooling tower 1, an ash unloading pipe 4, a silo pump 10, a pneumatic conveying pipe 17 and a coarse ash silo 18 connected in sequence.

[0026] The lower cone of the evaporative cooling tower 1 is used to capture the crude ash in the raw gas. The evaporative cooling tower 1 is equipped with a level meter 3, and the level of the evaporative cooling tower 1 can be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com