Intelligent safety device of hydraulic press

A safety protection device and hydraulic press technology, which is applied in the field of hydraulic presses, can solve the problems of hidden dangers of safety accidents, increased maintenance time, and high turnover rate of personnel, and achieve the effects of reducing maintenance time, high labor intensity, and eliminating equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

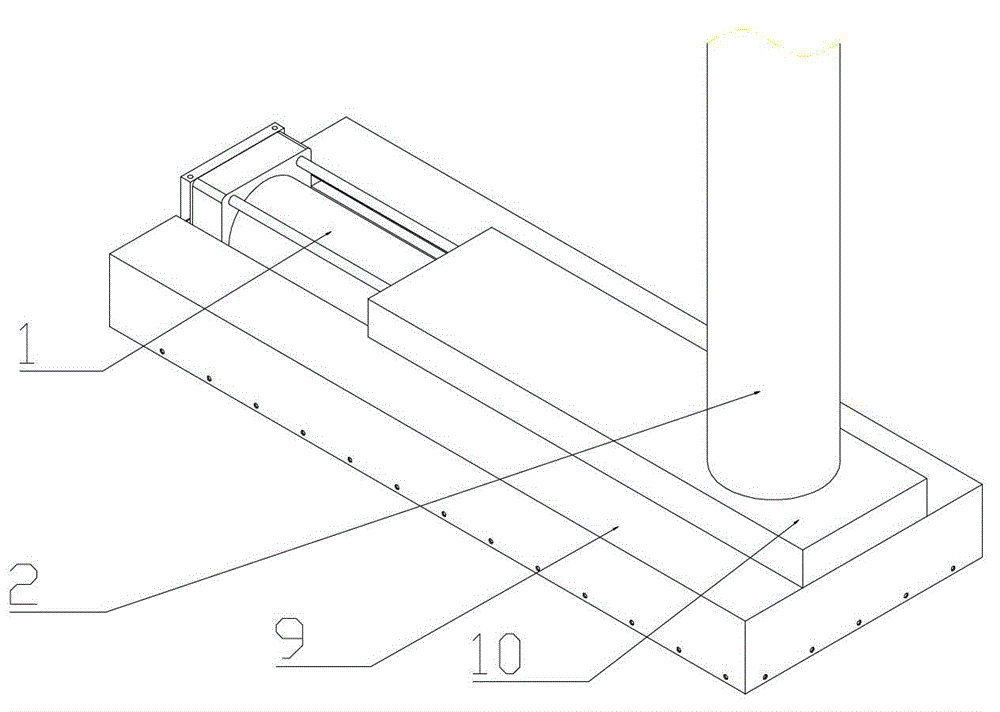

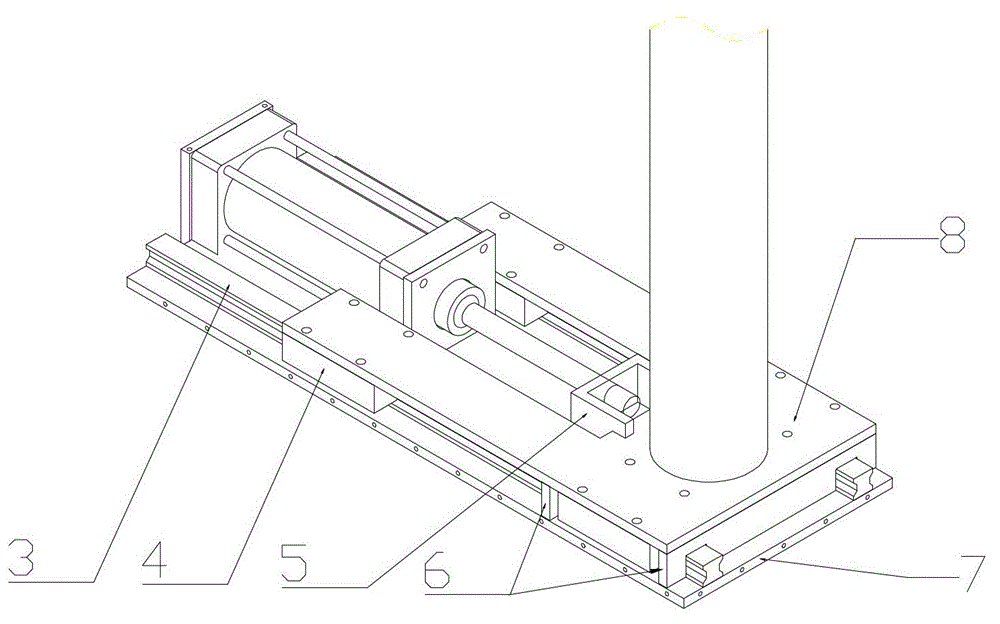

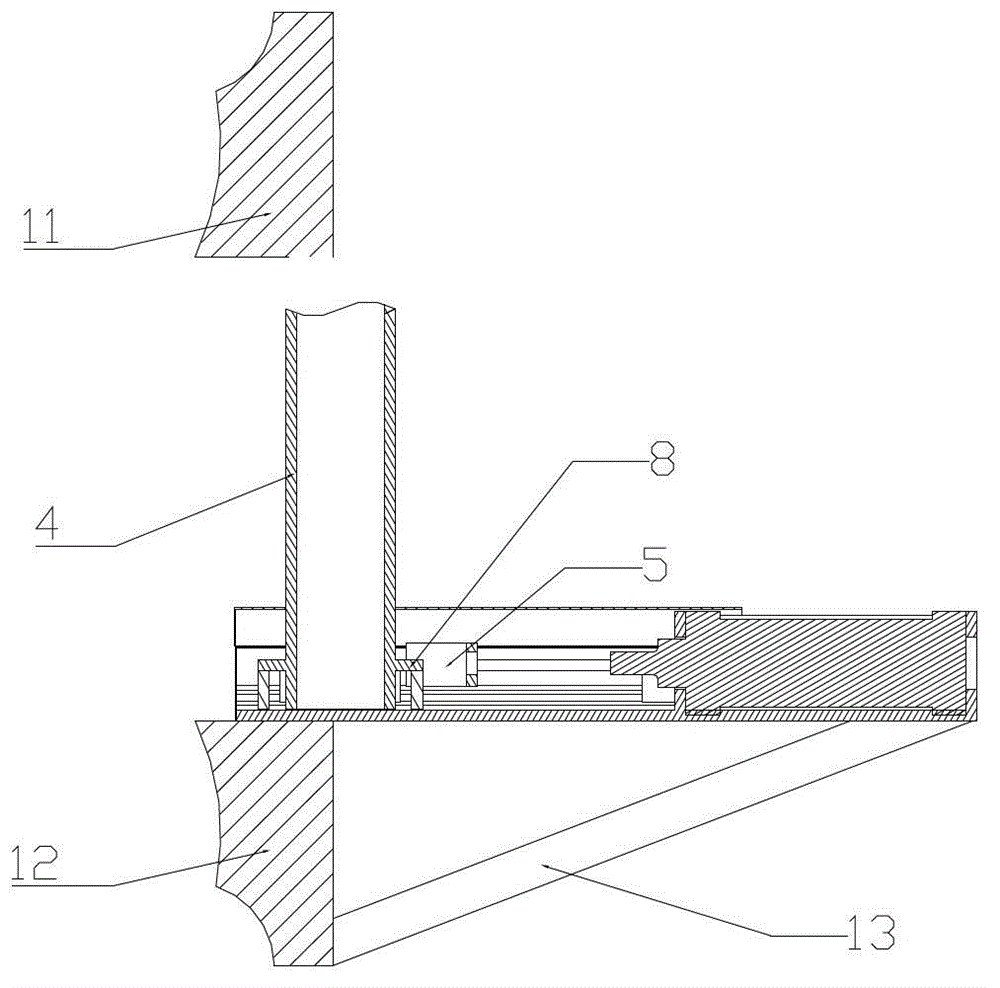

[0029] Such as figure 1 , 2 as shown,

[0030] The hydraulic machine intelligent safety protection device includes a safety column 2, a conveying device, and a control circuit; the conveying device includes a magnetic ring cylinder 1, a linear guide rail 3, a slider 4, a connecting plate 5, a reinforcing rib 6, and a mounting plate 7, wherein :

[0031] The magnetic ring cylinder 1 receives information and is responsible for the entry and exit of the safety column 2; the safety column 2 prevents the hydraulic machine table from falling; the linear guide rail 3 and the slider 4 ensure the smooth and brisk entry and exit of the safety column 2; the connecting plate 5 connects the magnetic ring cylinder 1 and the fixed plate 8. Adjust cylinder stroke. The ribs 6 prevent the deformation of the fixing plate 8 and friction with the mounting plate 7; the mounting plate 7 is fixed with the lower table 12 of the hydraulic press, and the safety column 2 is fixed with the equipment; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com