A method for analyzing nitrogen components of low-nitrogen steel samples in front of furnace

An analysis method and component analysis technology, applied in the field of steelmaking, can solve problems such as data instability, achieve the effect of less wear of the cutter head, ensure accuracy, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

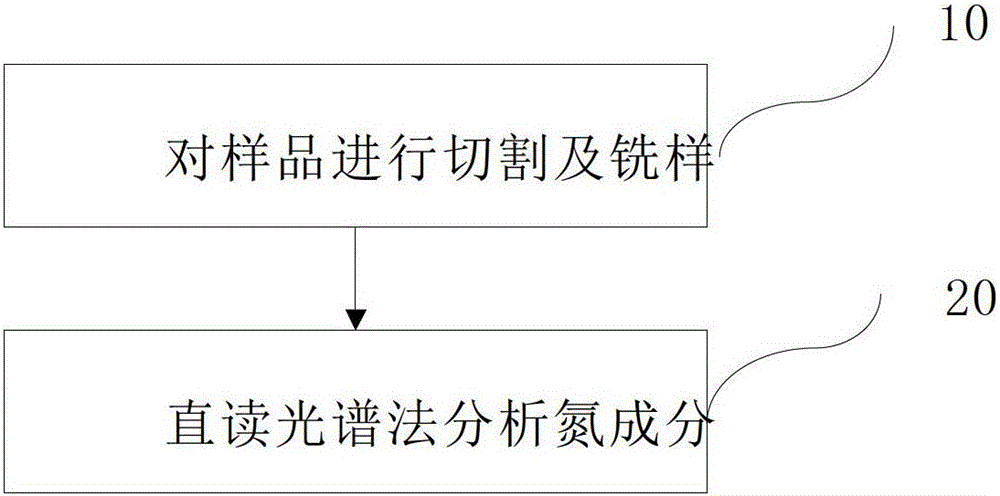

[0018] see figure 1 , the embodiment of the present invention provides a method for analyzing the nitrogen composition of the low-nitrogen steel sample in front of the furnace, including:

[0019] Step 10: Make a cylindrical sample and cut and mill the sample, specifically: take molten steel through a cylindrical sampler to make an upper diameter of 39cm-41cm, a lower diameter of 35cm-37cm, a height of A cylindrical sample of 68 cm to 70 cm. Cut at 1 / 3-1 / 4 of the top of the sample in the length direction of the sample. When cutting the sample, the cutting speed is 4500-4700 rpm. Mill the sample after cutting, so that the surface of the sample must have a certain regular texture and no blisters and shrinkage cavities on the surface. The sample depth is 15-20mm. Cool the milled sample to below 35°C.

[0020] Step 20: Analyze the nitrogen component of the sample after cutting and milling by direct-reading spectroscopy, specifically: keep the temperature of the laboratory wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com